Quartz rod structure for changing refractive index profile by external exposure method

A technology of refractive index distribution and quartz rods, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of complex production process, difficulty in meeting the requirements of high-quality quartz rods, and difficulty in effectively improving quality accuracy, so as to avoid Unstable and large loss, reduce the maximum power per unit volume, and reduce the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

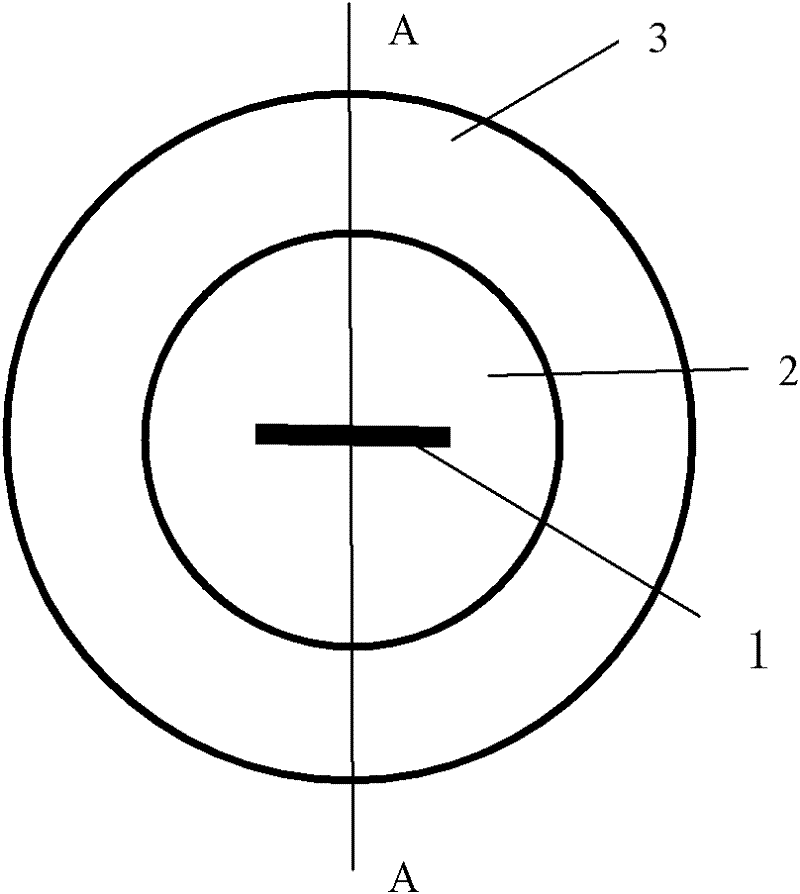

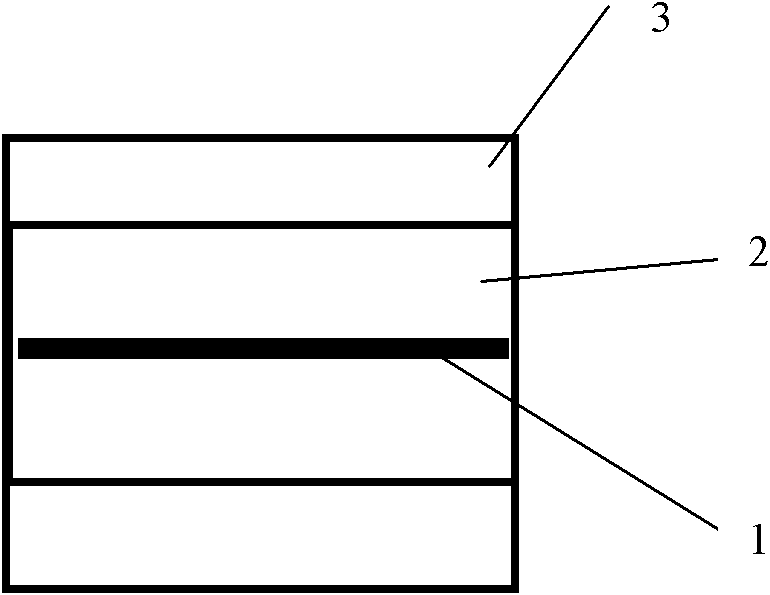

[0019] Embodiment 1, using external exposure method to change the refractive index distribution of the quartz rod structure, such as figure 1 , 2 , the quartz rod structure includes an exposure area 1 and an active quartz rod; the active quartz rod includes an active quartz rod core 2 and an outer cladding 3 , and the exposure area 1 is inside the active quartz rod core 2 .

[0020] The active quartz rod core 2 is a ytterbium-doped quartz rod with a radius of 3 mm. The thickness of the outer layer 3 is 1 mm, and the length of the active quartz rod is 0.5 mm.

[0021] The refractive index of the outer cladding 3 is selected to be 1.452, and the refractive index of the active quartz rod core 2 is 1.455.

[0022] From the left end face of the active quartz rod core 2, an ultraviolet laser is used to externally expose a 4*0.1mm rectangular area at the center of the active quartz rod core 2, so that the refractive index becomes 1.459, forming an exposure area 1.4* The 0.1mm rect...

Embodiment approach 2

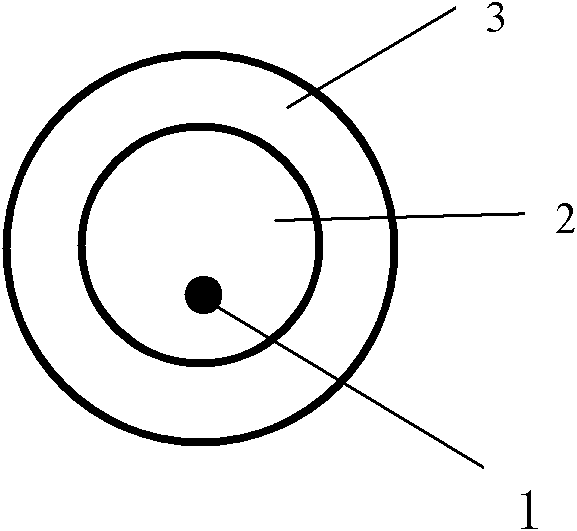

[0024] Embodiment 2, using external exposure method to change the quartz rod structure of the refractive index distribution, such as image 3 , the quartz rod structure includes: exposure area 1 and an active quartz rod. The active quartz rod includes: an active quartz rod core 2 and an outer cladding 3 , and the exposure area 1 is inside the active quartz rod core 2 .

[0025] The active quartz rod core 2 is an erbium-doped quartz rod with a radius of 0.5 mm. The thickness of the outer layer 3 is 1 mm, and the length of the active quartz rod is 10 mm.

[0026] The refractive index of the outer cladding 3 is selected to be 1.450, and the refractive index of the active quartz rod core 2 is selected to be 1.453.

[0027] From the left end face of the active quartz rod core 2, external exposure is performed on a circular area with a diameter of 10 μm at a distance of 10 μm from the center of the active quartz rod core 2, so that the refractive index becomes 1.455, and the expos...

Embodiment approach 3

[0029] Embodiment 3, using external exposure method to change the quartz rod structure of refractive index distribution, such as Figure 4 , the quartz rod structure includes: exposure area 1 and an active quartz rod. The active quartz rod includes: an active quartz rod core 2 and an outer cladding 3 , and the exposure area 1 is inside the active quartz rod core 2 .

[0030] The active quartz rod core 2 is a ytterbium-doped quartz rod with a radius of 0.5 mm. The thickness of the outer layer 3 is 62.5 μm, and the length of the active quartz rod is 20 mm.

[0031] The refractive index of the outer cladding 3 is selected to be 1.451, and the refractive index of the active quartz rod core 2 is 1.454.

[0032] From the left end face of the active quartz rod core 2, a femtosecond laser is used to externally expose a circular area with a diameter of 10 μm at the center of the active quartz rod core 2, so that the refractive index becomes 1.457, and the exposure area 1 is formed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com