Single mode fiber (SMF) laser with large effective area by changing cladding index distribution

A technology of cladding refractive index and effective area, which is applied in the field of large effective area single-mode fiber lasers, can solve the problem of inability to have both single-mode and high-power lasers, reduce the maximum power per unit volume, and is not easy to nonlinear effects. , the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

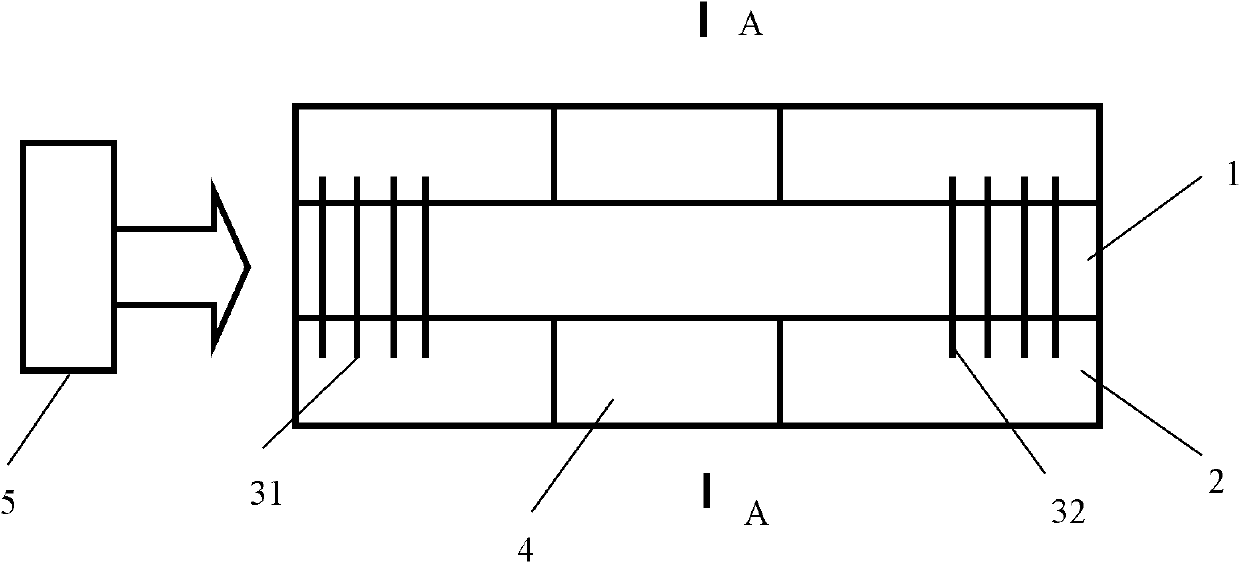

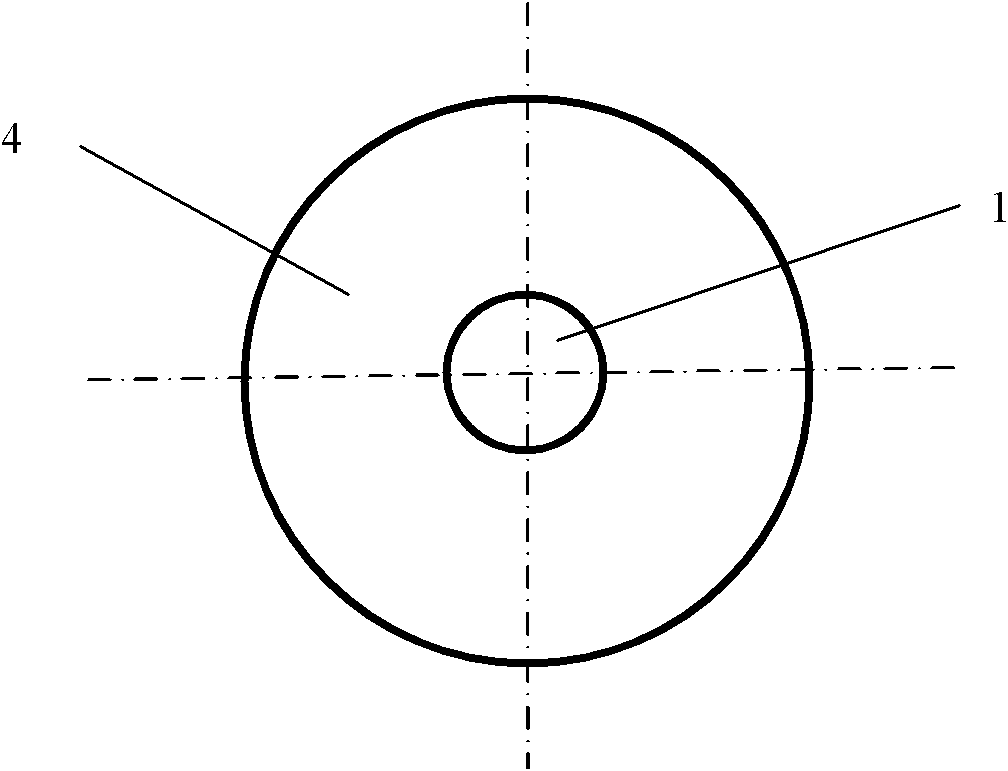

[0027] Large effective area single-mode fiber lasers by changing the refractive index distribution of the cladding, such as figure 1 , 2 shown. The laser includes: an optical fiber, a first fiber grating 31 written at both ends of the fiber core 1 , a second fiber grating 32 , and a pumping source 5 .

[0028] The refractive index of the core 1 of the optical fiber is 1.6, and the refractive index of the cladding 2 is 1.4.

[0029] Use hydrofluoric acid solution to etch away the annular region between the first fiber grating 31 and the second fiber grating 32, the axial length is 1 mm, the thickness of the ring is 50 microns, and it is filled with quartz with a refractive index of 1.5 to form a filling District 4.

[0030] The distance between the first fiber grating 31 and the second fiber grating 32 is 50 cm.

[0031] The radius of the core 1 is 8 microns, the thickness of the cladding 2 is 50 microns, and the axial length of the filling region 4 is 1 mm.

[0032] The p...

Embodiment approach 2

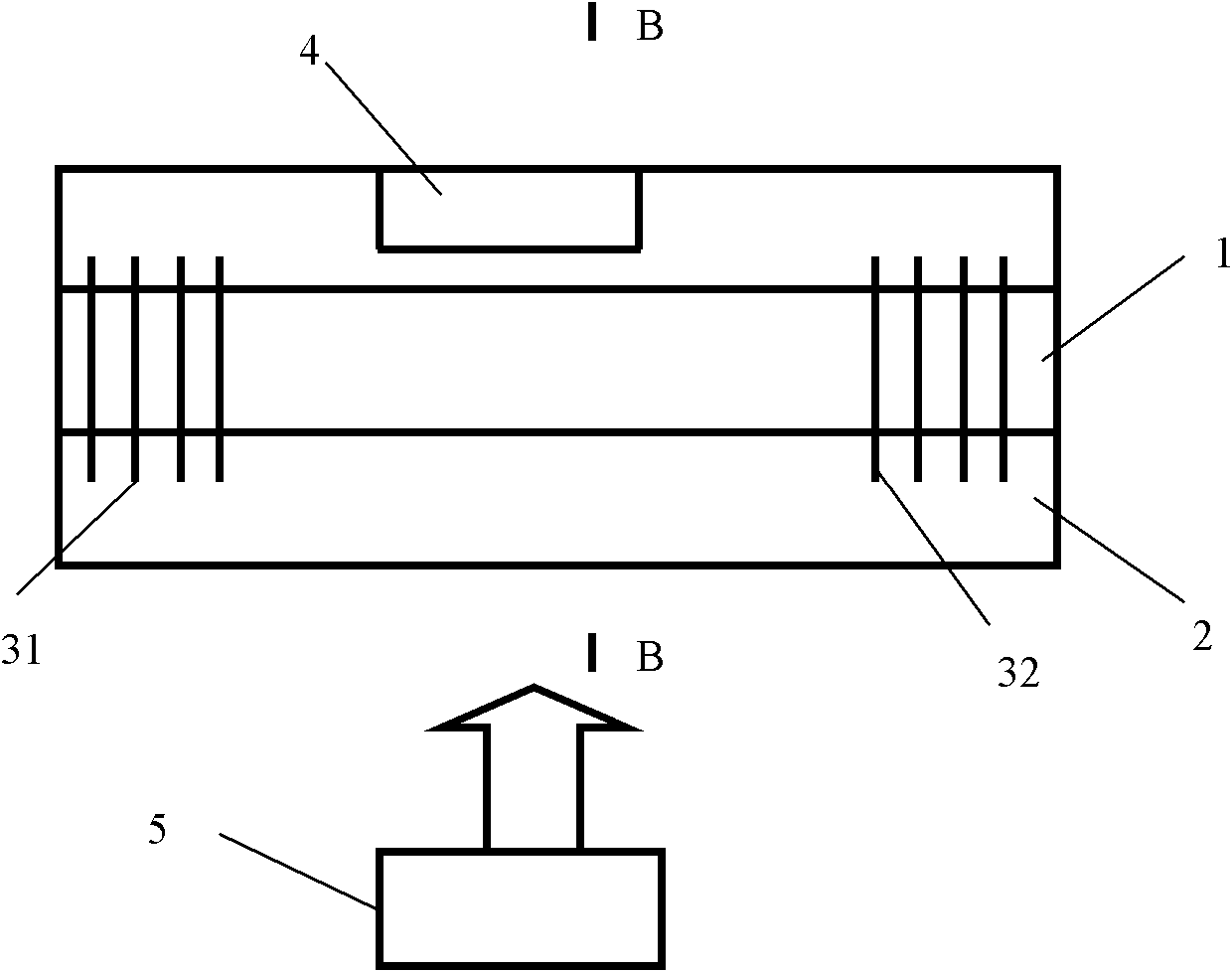

[0034] A large effective area single-mode fiber laser with a D-shaped filling area by changing the refractive index distribution of the cladding, such as image 3 , 4 shown. The laser includes: an optical fiber, a first fiber grating 31 written at both ends of the fiber core 1 , a second fiber grating 32 , and a pumping source 5 .

[0035] The refractive index of the core 1 of the optical fiber is 1.9, and the refractive index of the cladding 2 is 1.7.

[0036] Use hydrofluoric acid solution to etch away the shape between the first fiber Bragg grating 31 and the second fiber Bragg grating 32. The shape is D-shaped, the chord height is 10 microns, and the axial length is 10 mm. Fill it with quartz with a refractive index of 1.8 to form a filling District 4.

[0037] The radius of the core 1 is 100 microns, and the thickness of the cladding 2 is 100 microns.

[0038] The distance between the first fiber grating 31 and the second fiber grating 32 is 5 meters.

[0039] The pu...

Embodiment approach 3

[0041] A large effective area single-mode fiber laser whose filling area is a helical rectangular groove by changing the refractive index distribution of the cladding, such as Figure 5 shown. The laser includes: an optical fiber, a first fiber grating 31 written at both ends of the fiber core 1 , a second fiber grating 32 , and a pumping source 5 .

[0042] The refractive index of the core 1 of the optical fiber is 1.8, and the refractive index of the cladding 2 is 1.6.

[0043] Corrode the filling area 4 between the first fiber grating 31 and the second fiber grating 32 with a hydrofluoric acid solution to form a spiral rectangular groove, the groove width is 10 microns, the pitch is 100 microns, and the groove depth is the thickness of the cladding 2, to refract Filled with quartz with a ratio of 1.7 to form the filled region 4 .

[0044] The radius of the core 1 is 50 microns, and the thickness of the cladding 2 is 80 microns.

[0045] The distance between the first fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com