Sand box turning mechanism

A technology of turning over boxes and sand boxes, which is applied in the direction of molding machines, casting molding equipment, metal processing equipment, etc., and can solve the problems of stability stuck, unstable way of turning over boxes, frequent frequency of turning over boxes, etc., so as to avoid jamming Stop and stop, suitable for continuous operation, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

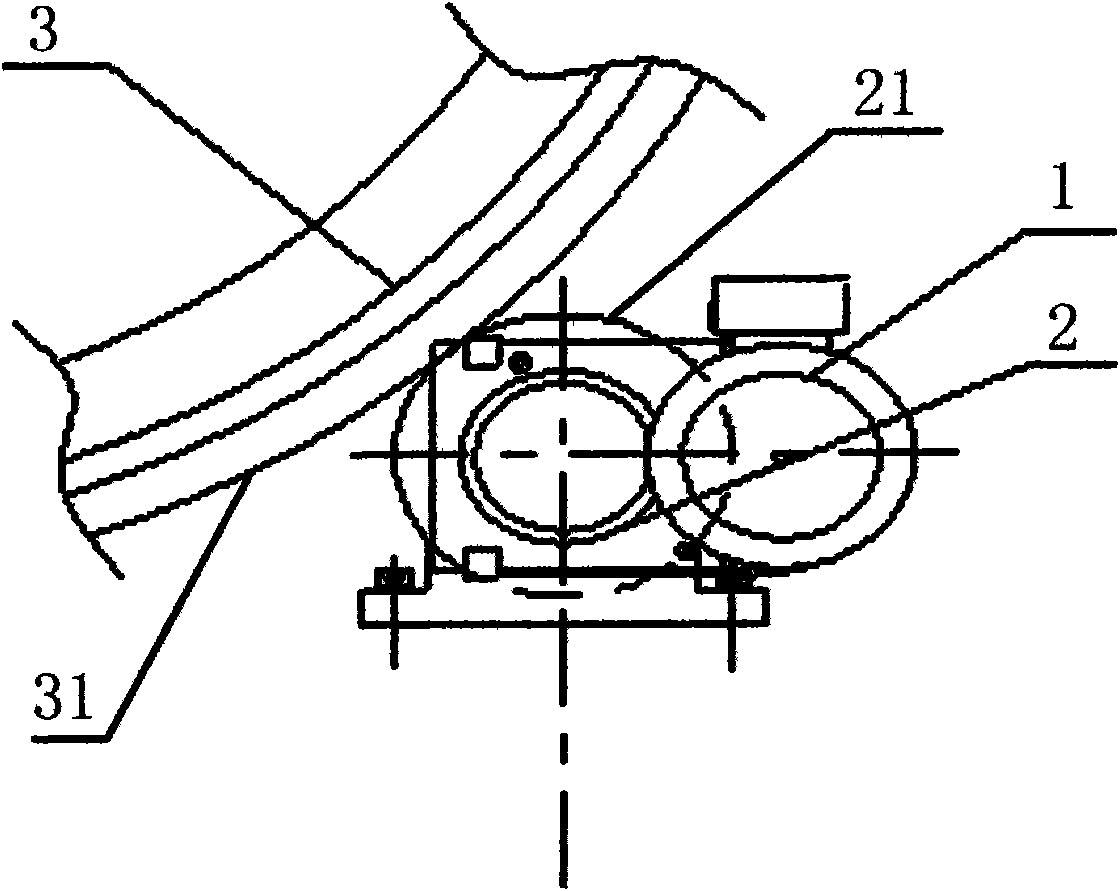

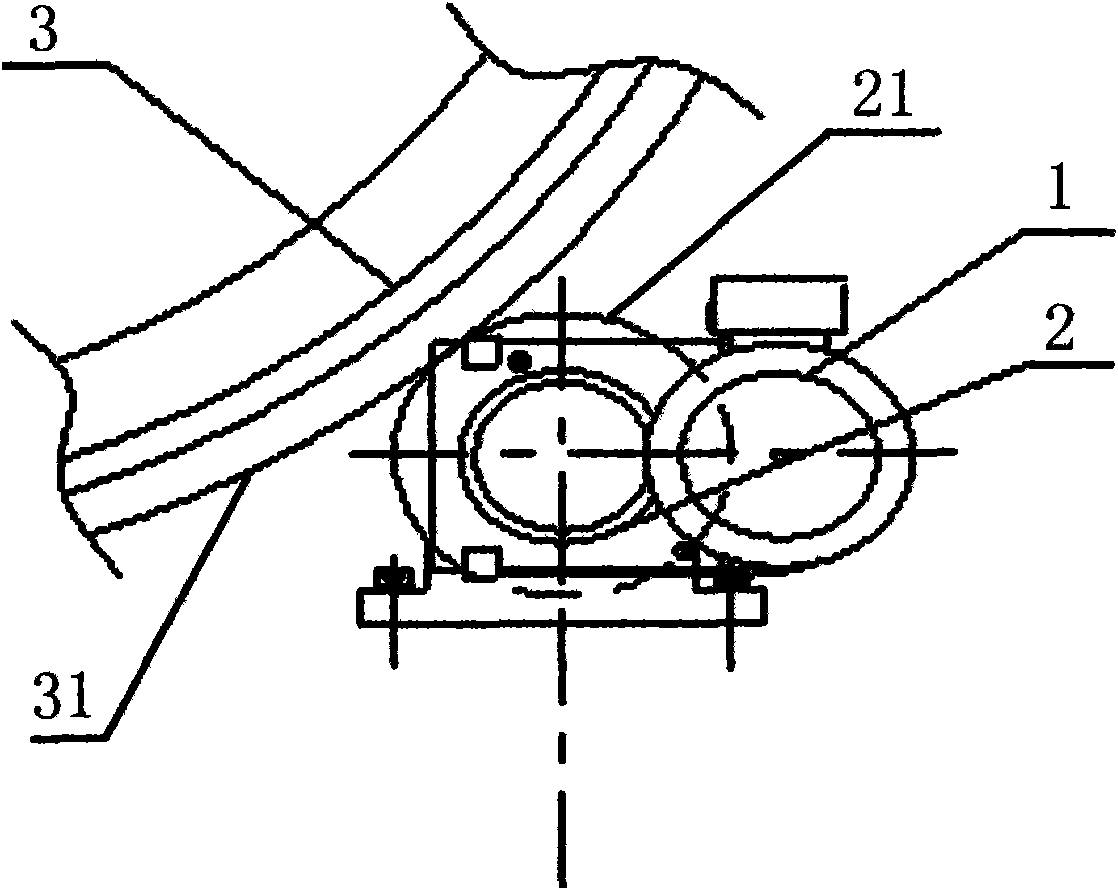

[0012] Such as figure 1 In the sand box turning mechanism shown, the outer rim surface 21 of the friction wheel 2 controlled by the motor 1 is a friction surface, and the turning machine wheel 3 controls its turning operation by being connected with the turned sand box. The outer rim surface 31 of the box machine wheel 3 is also a friction surface, wherein the two friction surfaces of the outer rim surface 21 and the outer rim surface 31 abut against each other in a circumscribed manner, driven by the motor 1, the rotating friction wheel 2 is driven by the friction force Drive the box turning machine wheel 3, thereby indirectly realize turning over the box, and reach the purpose of turning over the box smoothly.

[0013] The sand box turning mechanism provided by the invention solves the problem of the stability of turning the box, and solves the problems of easy slipping and instability when turning the box in the existing mechanism. Faults rarely occur during use, and the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com