Automobile body structure on lower part of automobile with moveable top

A technology of movable roof and body, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problems of insufficient strength and rigidity of non-cage body, and achieve the effect of strengthening rigidity, local strength, and bending resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

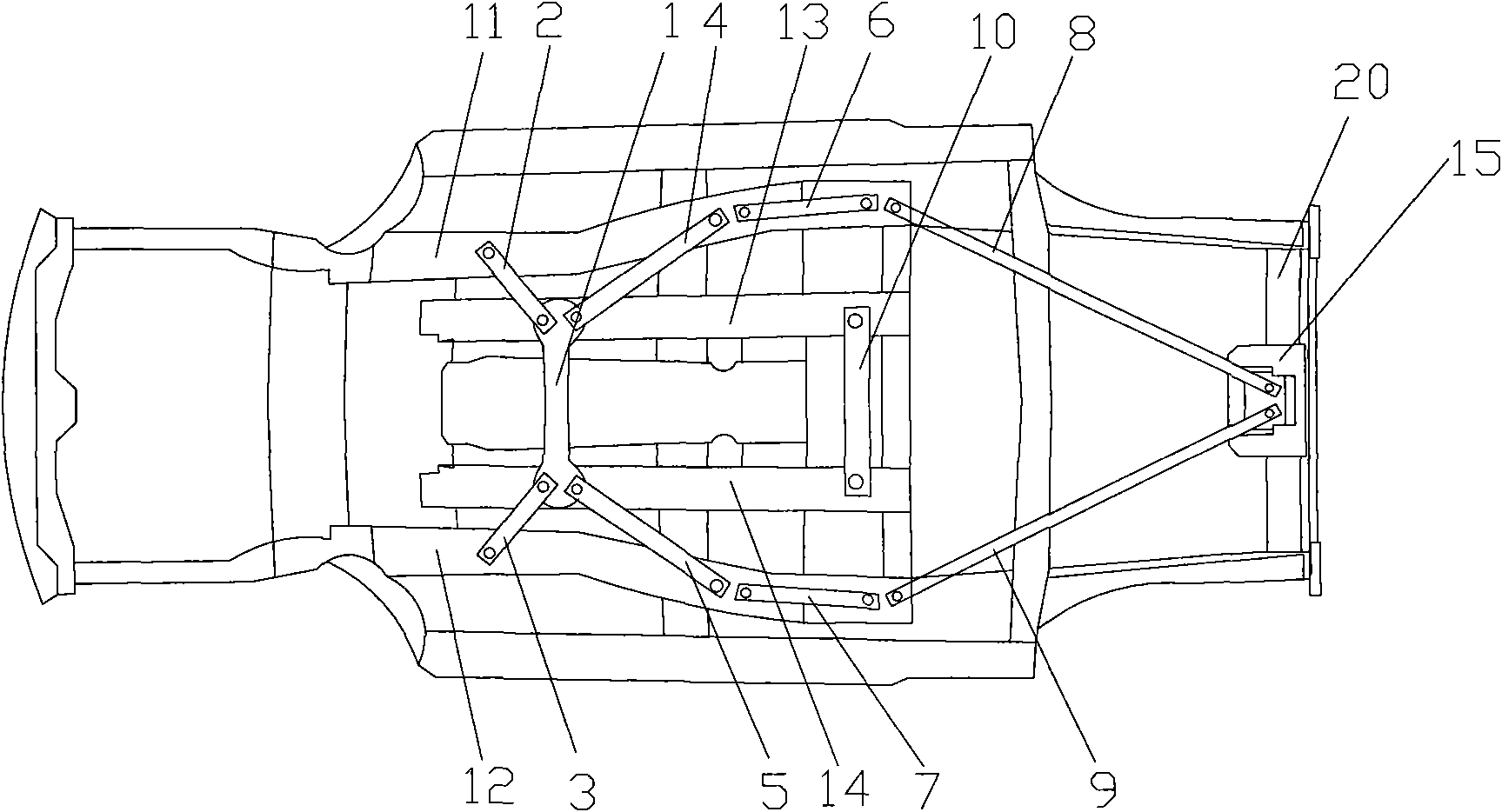

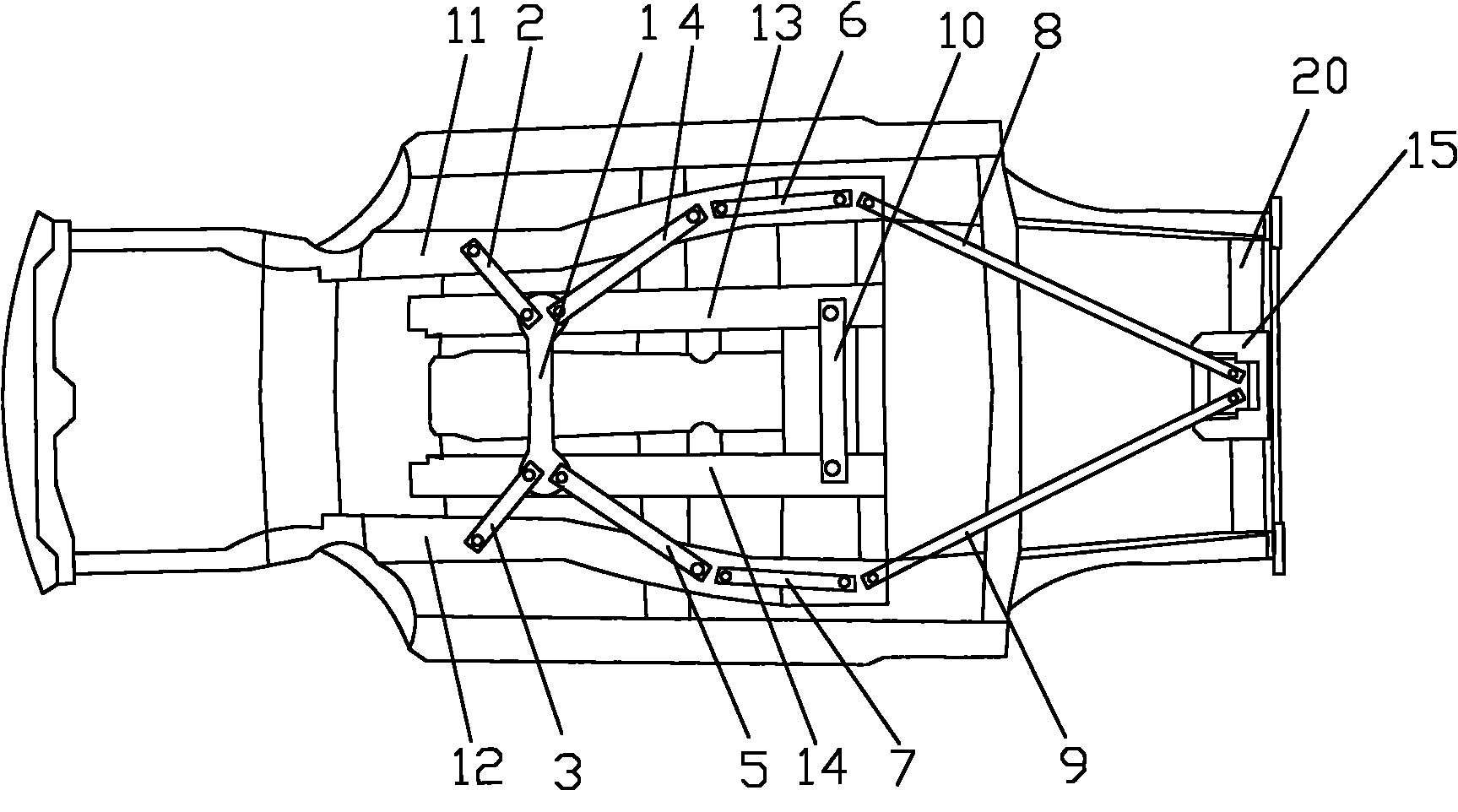

[0012] Example 1, as figure 1 As shown, a lower body structure of an automobile with a movable roof includes a left longitudinal beam 11 and a right longitudinal beam 12. The left and right longitudinal beams are symmetrically distributed on both sides of the vehicle body, and are arranged on the rear cross beam 20 at the rear end of the vehicle body; The inner side is also symmetrically provided with a left inner longitudinal beam 13 and a right inner longitudinal beam 14, and a reinforcing beam 1 is arranged between the front ends of the two inner longitudinal beams; A set of inclined support plates, including a first inclined support plate 2, a second inclined support plate 4, one end of the two inclined support plates are respectively fixed on the left longitudinal beam 11, and the other ends are respectively at the position of the reinforcing beam 1 and the left inner longitudinal beam 13. connected to form a triangular structure. A second group of oblique support plates...

Embodiment 2

[0013] Embodiment 2, on the basis of the technical solution of Embodiment 1, a fifth support plate 8 is further arranged between the rear cross beam 20 and the left longitudinal beam 11 , and between the rear cross beam 20 and the right longitudinal beam 12 A sixth support plate 9 is also provided. In order to facilitate the fixing of the fifth support plate 8 and the sixth support plate 9, a bracket 15 is provided in the middle of the rear cross member 20, and the fifth support plate 8 is fixedly connected between the bracket 15 and the left longitudinal beam 11. The support plate 9 is fixedly connected between the bracket 15 and the right longitudinal beam 12, and the fifth support plate 8 and the sixth support plate 9 are arranged in a V-shape, which can well enhance the rigidity of the rear end of the vehicle body.

Embodiment 3

[0014] Embodiment 3, on the basis of the technical solution of Embodiment 1 or Embodiment 2, a first support plate 6 is provided at the longitudinal middle position of the left longitudinal beam 11, and the support plate 6 is located between the second inclined support plate 4 and the first support plate 6. The five support plates 8 are between the fixed points on the left longitudinal beam 11 ; a second support plate 7 is provided at the position of the right longitudinal beam 12 corresponding to the first support plate 6 . The first support plate 6 and the second support plate 7 can enhance the bending resistance of the whole vehicle, and will not cause an obvious weak area in the middle of the vehicle under bending conditions, and when the entire front and rear directions are bent, the deformation is relatively evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com