Submarine pipeline buckling preventing device, and manufacturing method and mounting method thereof

A kind of submarine pipeline, technology of making method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

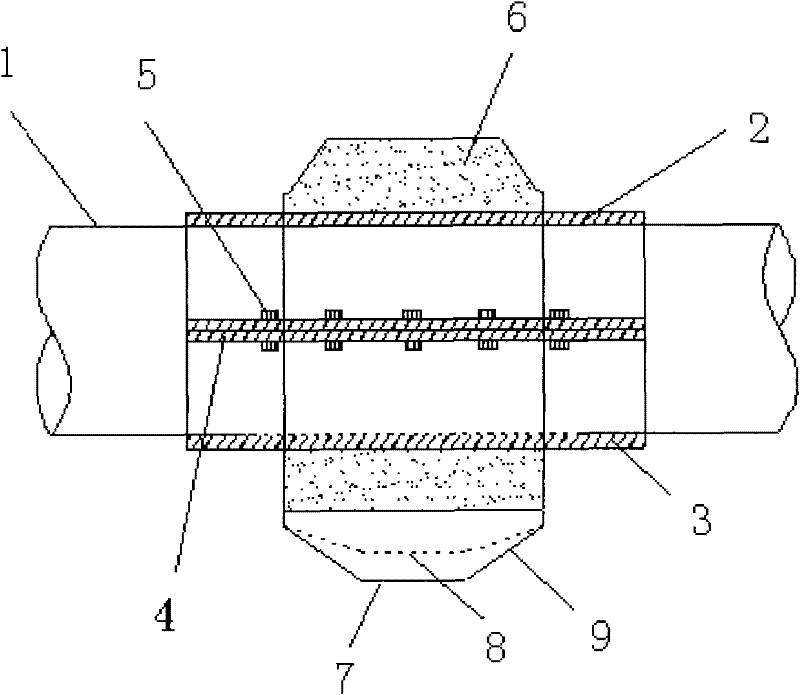

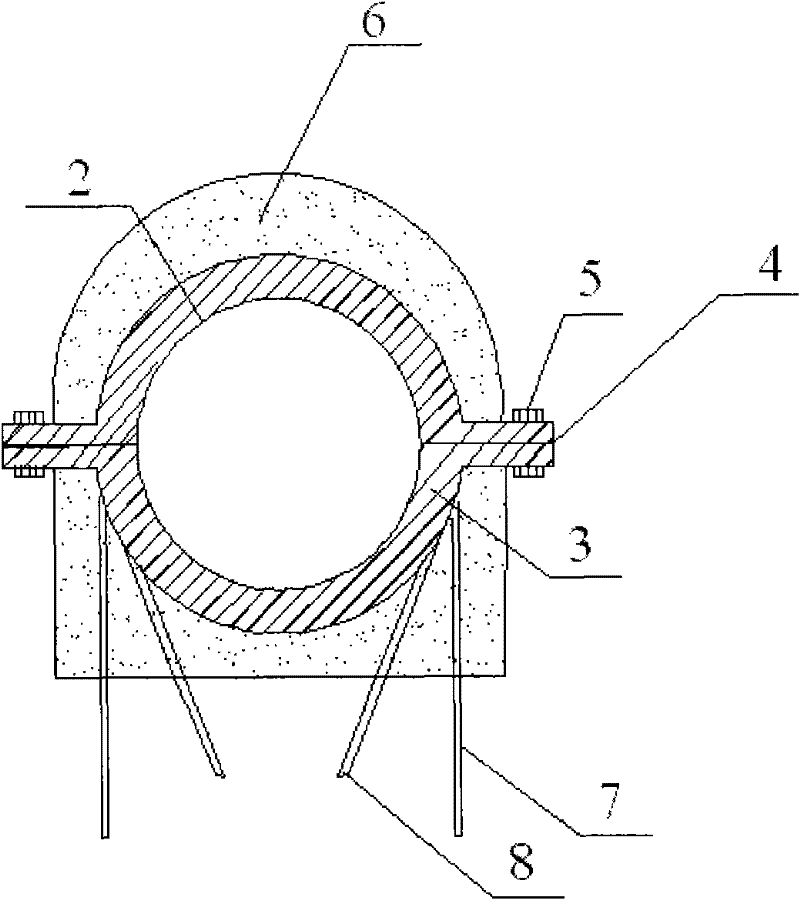

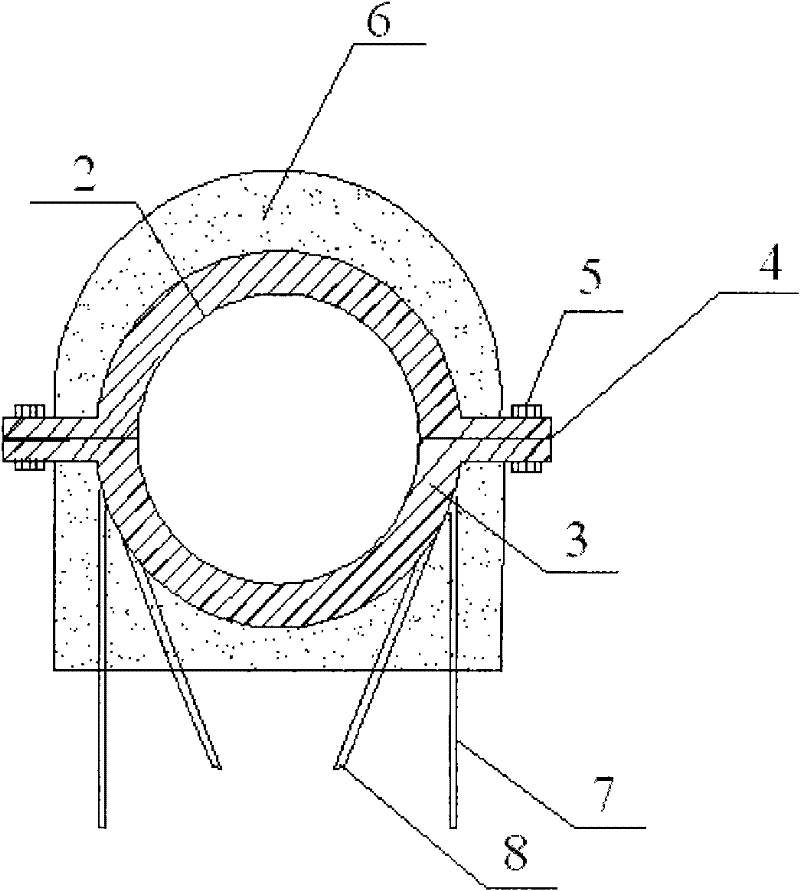

[0016] Such as figure 1 , figure 2 As shown, the present invention includes thick-walled shells 2, 3 that can be stuck on the outer wall of the submarine pipeline 1 from the top and bottom, and the two sections are ring-shaped thick-walled shells 2, 3. The upper and lower housings 2, 3 can be connected as a whole through the mounting holes and bolts 5 provided on the eye plate 4. The upper and lower casings 2 and 3 can be made of the same material as the submarine pipeline 1, for example: APLX65 or X70, X80 grade steel. Both shells 2 and 3 are poured with concrete briquettes 6 with a horseshoe-shaped cross-section. Two vertical anchor plates 7 and two oblique anchor plates 8 are welded symmetrically on both sides of the lower shell 3. Each anchor plate 7, The axial width of 8 along the lower shell 3 is the same as the axial width of the concrete b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com