Connector

A connector and housing technology, which is applied in the direction of connection, connection component installation, and connection device components, etc., can solve the problems of easy loosening of the fixed structure and low assembly efficiency, and achieve strong safety, improve assembly efficiency, and improve installation. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Further detailed description will be made below in conjunction with the accompanying drawings and preferred embodiments.

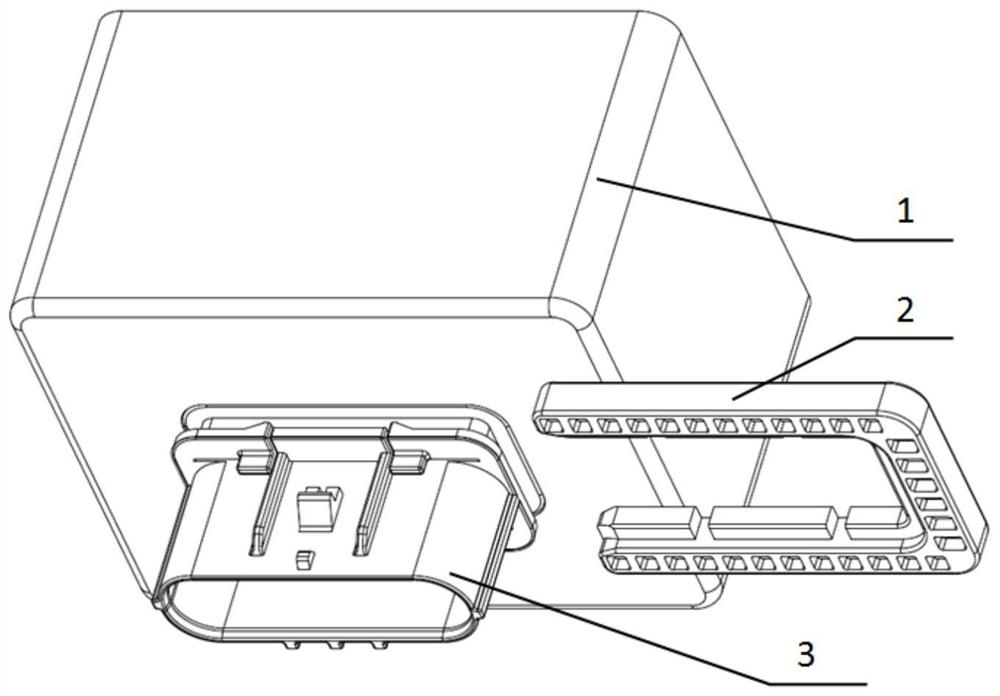

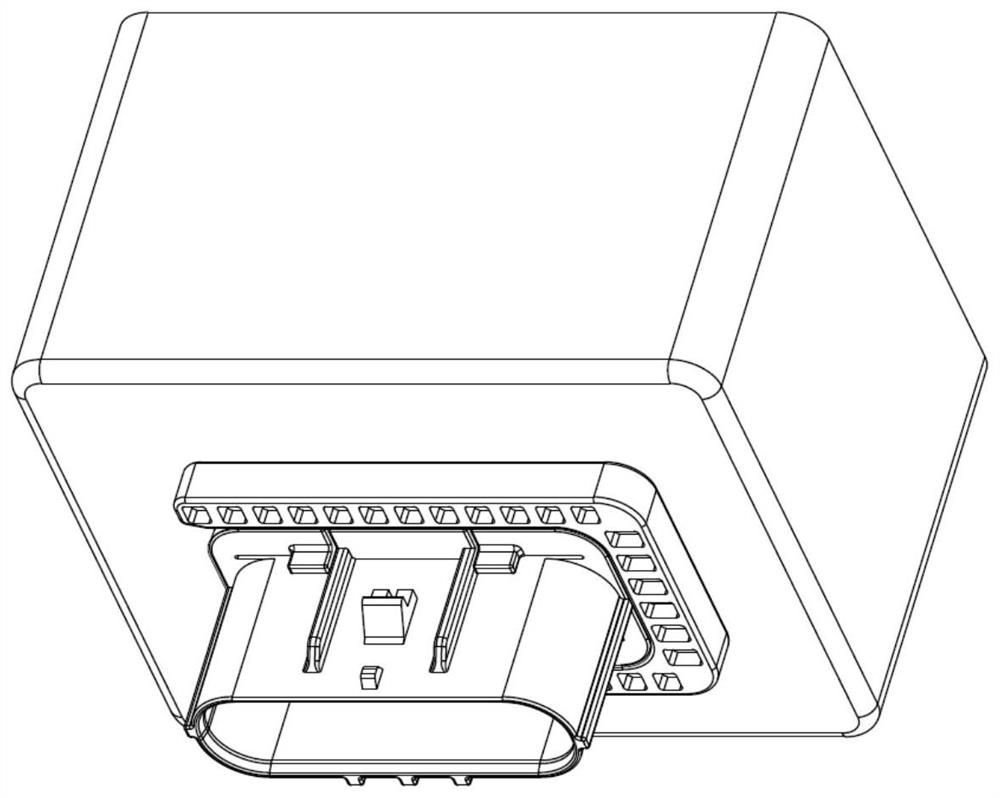

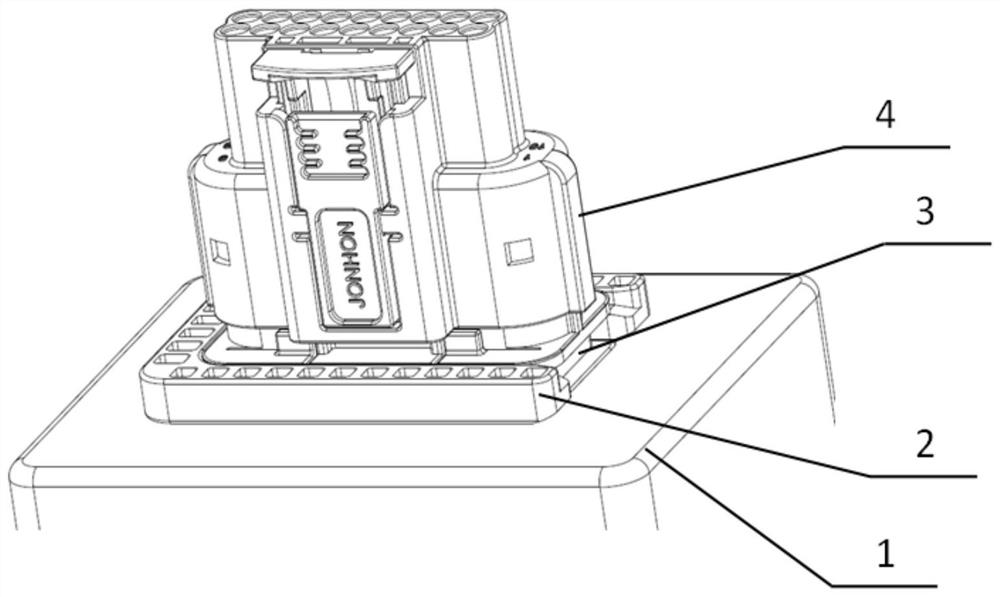

[0028] A specific embodiment of a connector of the present invention is Figure 1 to Figure 7 As shown, including the socket housing 3 and the installation lock 2, the front end of the socket housing is defined as the socket end mated with the front end of the adapter plug housing 4, and the rear end of the socket housing points to the front direction for assembly. Wearing direction in the equipment panel: the front end of the socket housing 3 passes through the wearing hole 11 on the equipment panel 1 along the wearing direction, and the rear end of the socket housing 3 is provided with a stop and fit with the inner wall of the equipment panel 1 to The flange 31 that realizes the constraint of the socket housing along the wearing direction, the installation lock 2 is inserted into the guide groove 32 opened on the socket housing along the perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com