Hot-gas bypass defrosting system for variable-frequency air conditioner

A technology for hot gas bypass defrosting and inverter air conditioners, which is applied in space heating and ventilation, heating and ventilation control systems, heating and ventilation safety systems, etc. To ensure the effect of defrosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

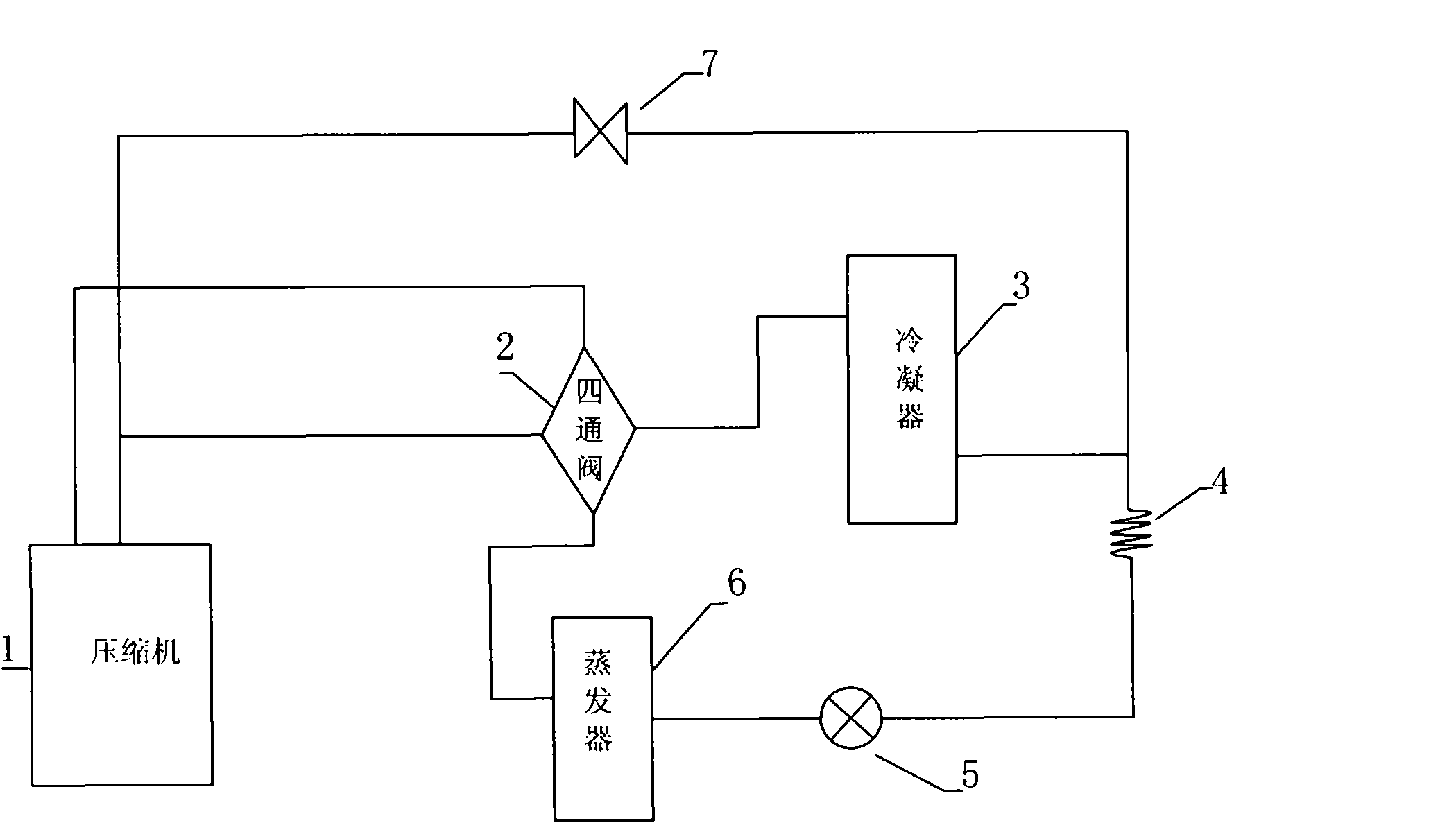

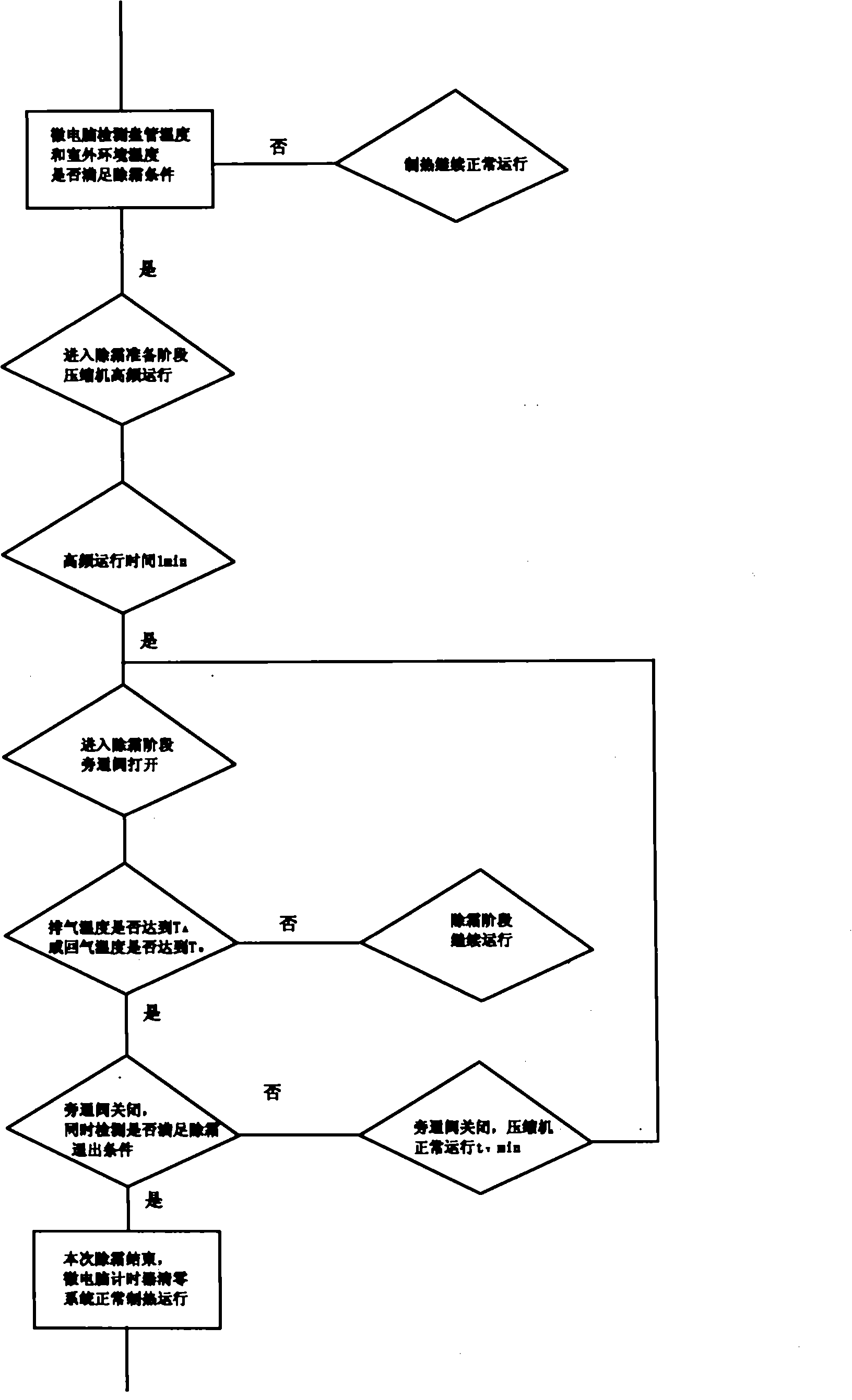

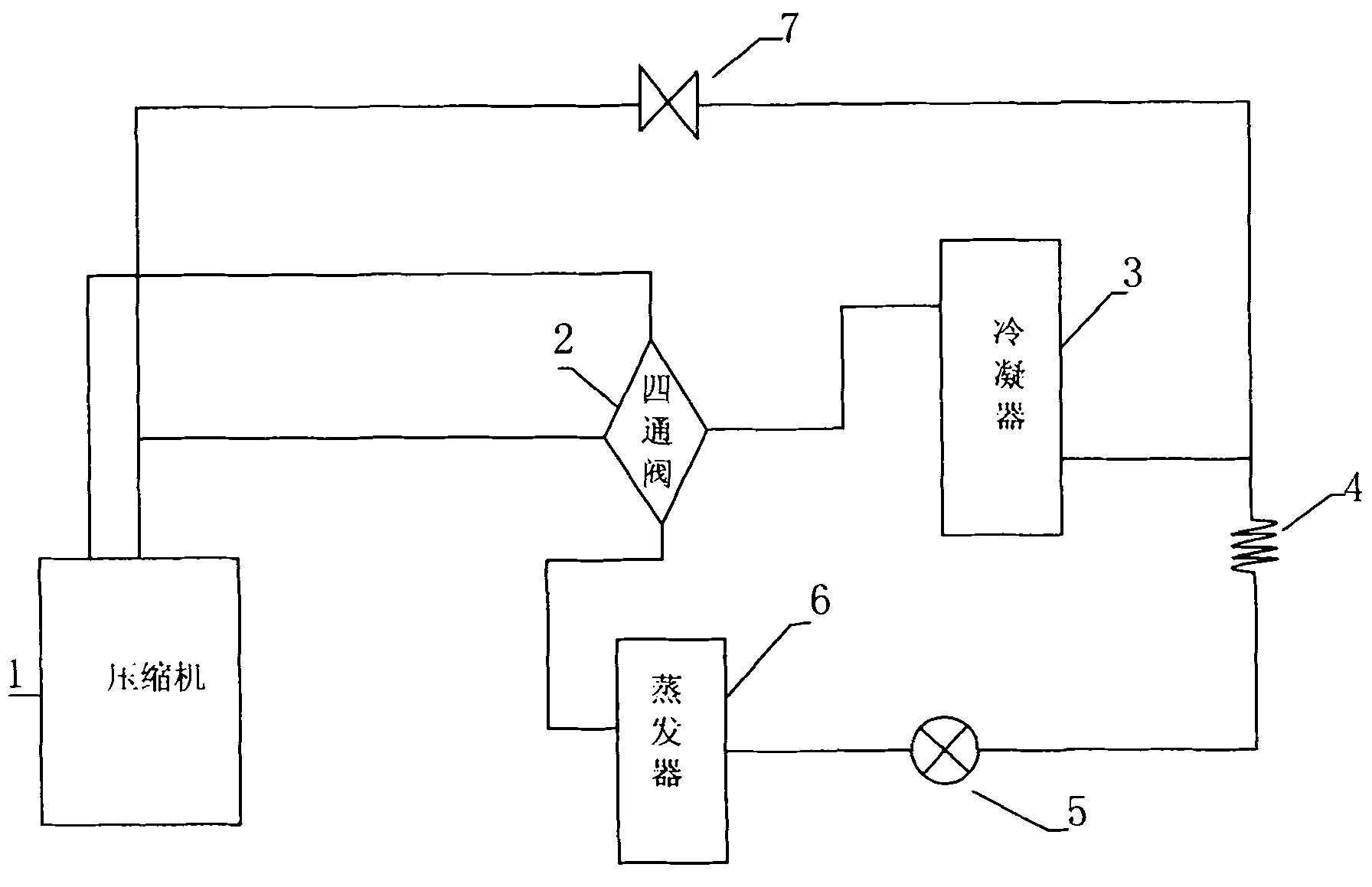

[0008] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 And attached figure 2 , the hot gas bypass defrosting system described in this embodiment, at first, install a temperature detector in the exhaust pipe of the compressor 1, the air return pipe and the 3 coils of the condenser respectively, and connect with the microcomputer, the temperature detector will detect The received temperature data is transmitted to the microcomputer, and the microcomputer analyzes and compares the received data. When the intermediate temperature of the condenser coil and the outdoor ambient temperature do not meet the conditions for entering defrosting, the compressor will run normally and continue to heat; When the intermediate temperature of the condenser coil and the outdoor ambient temperature meet the conditions for defrosting, the microcomputer sends an instructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com