Defrosting heating pipe component

A technology of heating tubes and components, which is applied in the field of defrosting heating tube components, can solve the problems of reduced heat exchange capacity of evaporators, high condensation pressure of refrigeration equipment, and large pressure difference between high and low pressures, so as to increase the heat exchange area and increase the defrosting capacity. Frost efficiency, effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

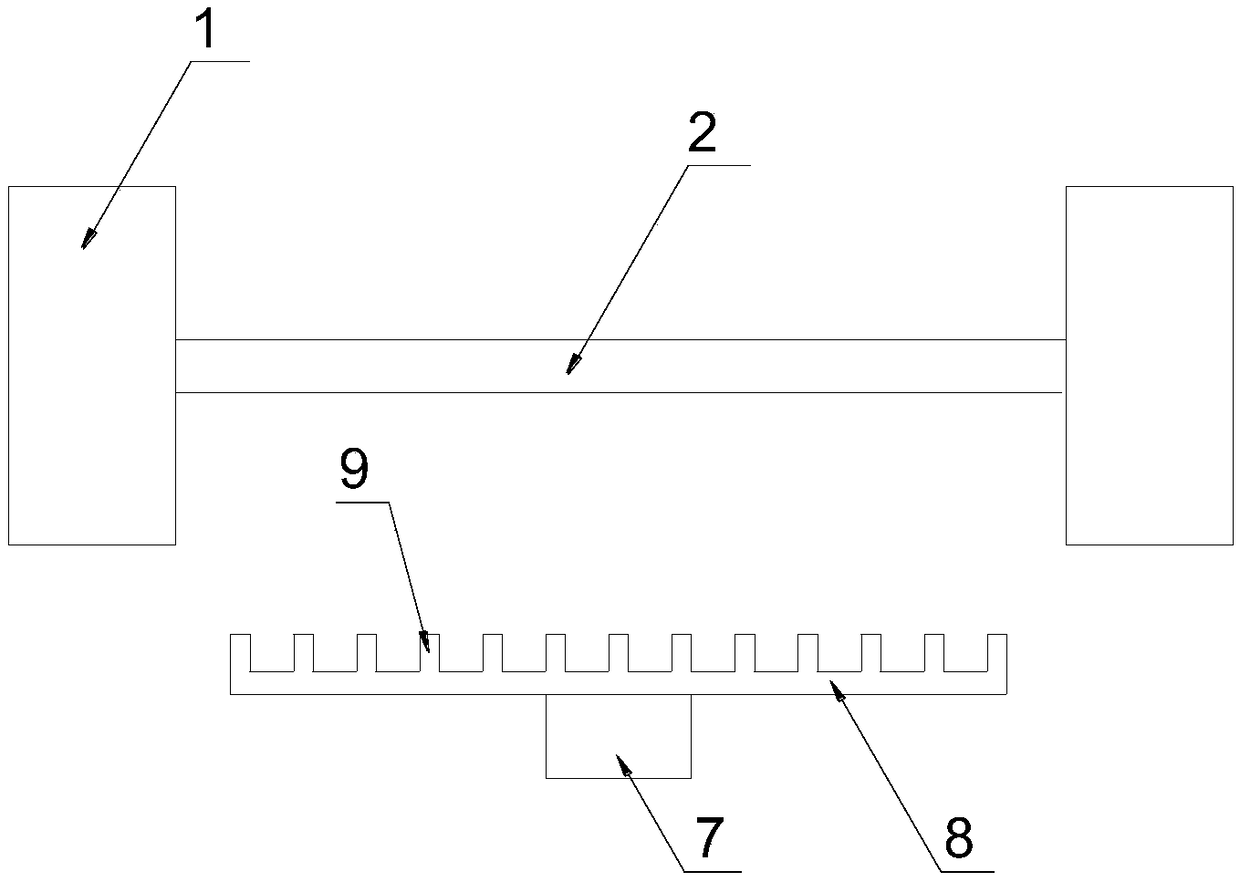

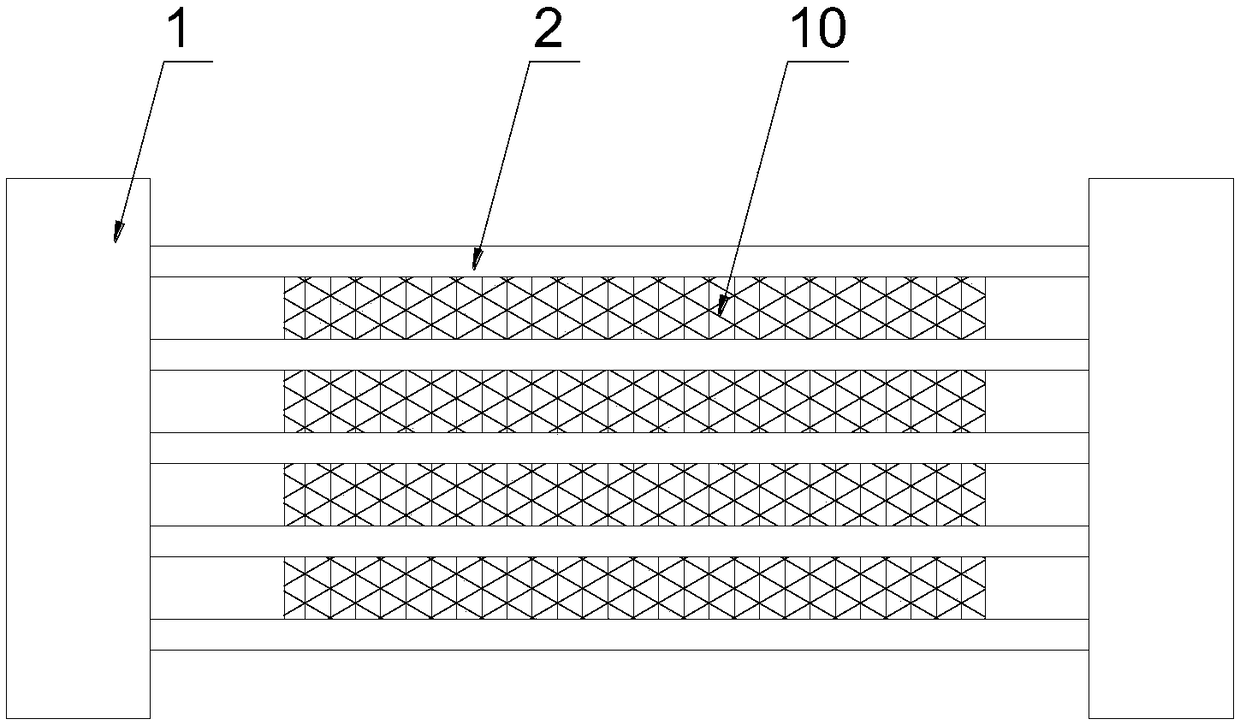

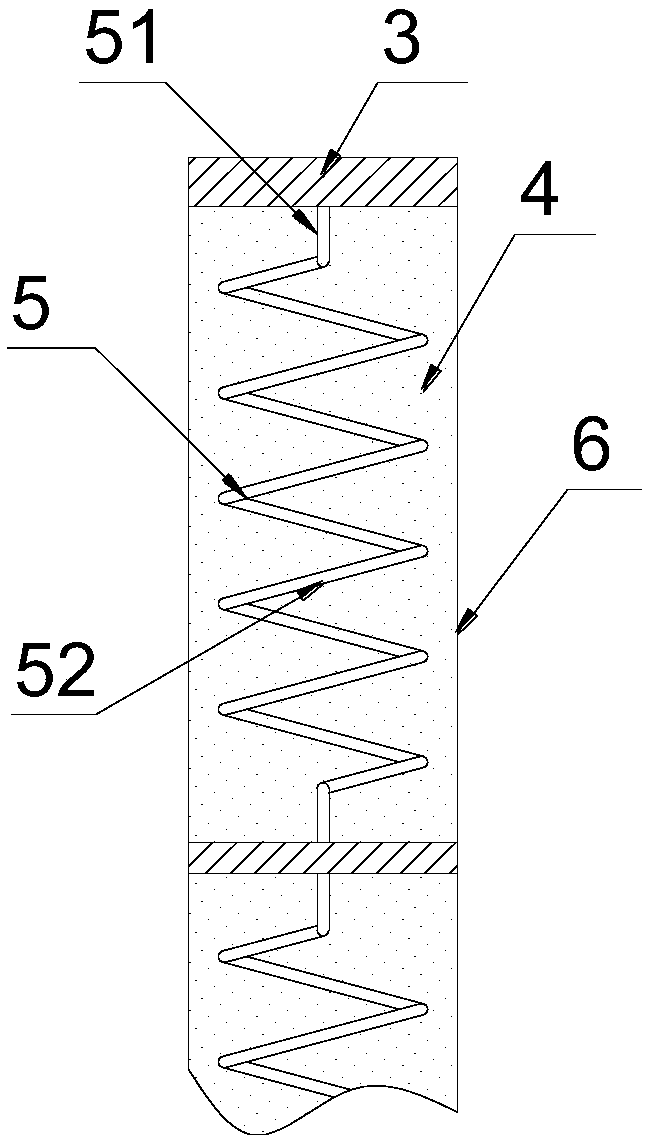

[0021] like Figure 1-3 as shown, figure 1 It is the front view of the defrosting heating tube assembly proposed by the present invention, figure 2 It is a top view of the defrosting heating tube assembly proposed by the present invention, image 3 It is a structural schematic diagram of the heating mechanism in the defrosting heating tube assembly proposed by the present invention.

[0022] refer to Figure 1-3 , a defrosting heating tube assembly proposed by the present invention, including a mounting base 1, a heating mechanism 2, a heat dissipation net 10, a fan 7, an air pipe 8 and an air spray head 9; wherein, the heating mechanism 2 includes an insulating member 3, insulating heat-conducting particles 4 , heating wire 5 and metal tube 6;

[0023] The heating mechanism 2 is arranged in a row in parallel, the two ends of the heating mechanism 2 are fixed on the two mounting bases 1, and the heating mechanism 2 is electrically connected to the mounting base 1;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com