Air conditioner defrosting control method, control device and air conditioner

A control method and technology for an air conditioner are applied in the field of air conditioners, air conditioner defrosting control methods, and control devices, and can solve the problems of inability to ensure clean defrosting and excess output power of compressors, so as to improve heating comfort and control. Thermal performance, the effect of reducing the attenuation of heating capacity and shortening the defrost cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

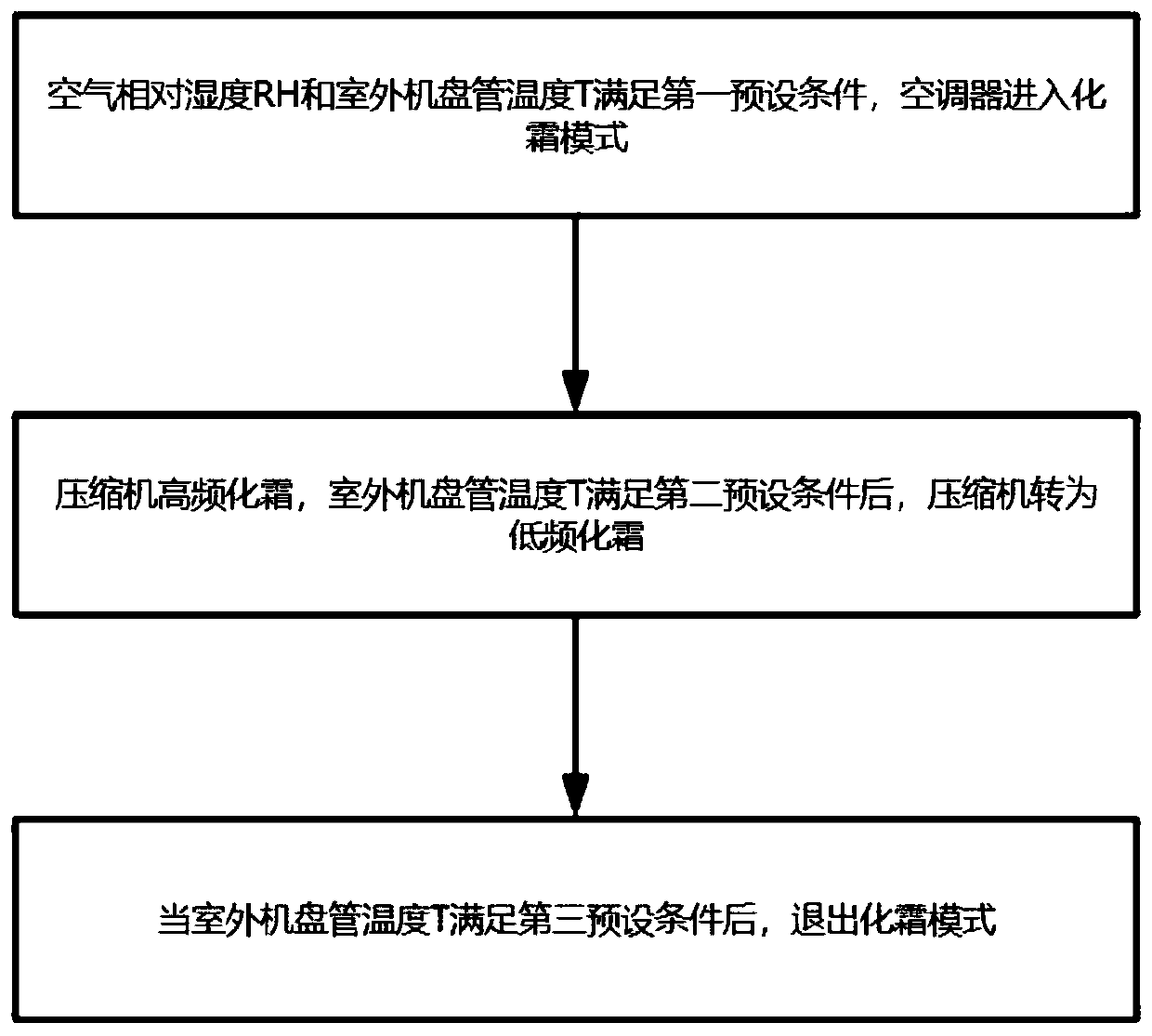

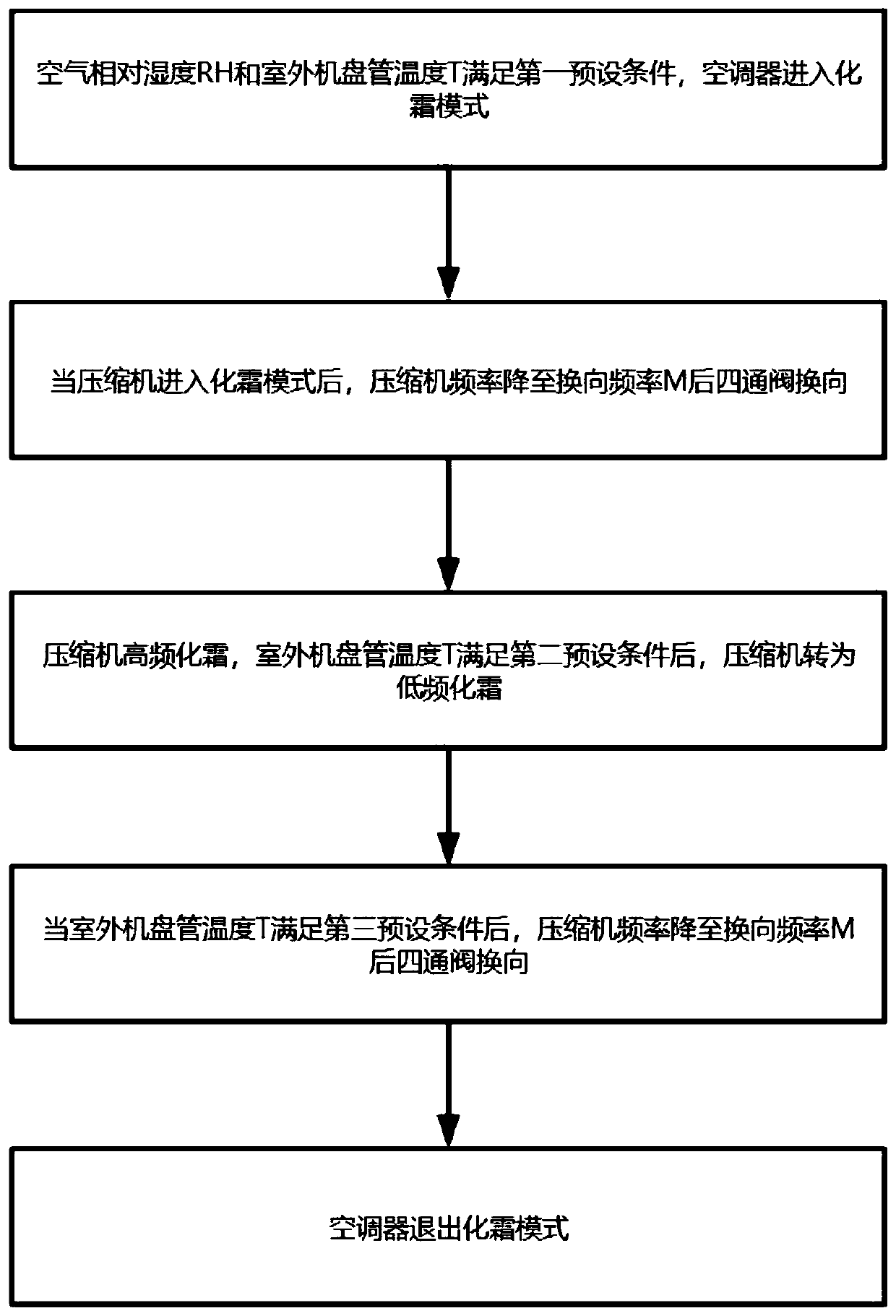

[0035] A defrosting control method for an air conditioner, comprising the following steps:

[0036] Step S100, after the relative air humidity RH and the outdoor unit coil temperature T meet the first preset condition, the air conditioner enters the defrosting mode;

[0037] The first preset condition includes: the air conditioner runs in heating mode for a first preset time t1;

[0038] The first preset time t1 is preferably 45 minutes. Allow the air conditioner to run for a period of time before performing defrosting detection to prevent the defrosting mode immediately after the air conditioner is started. At this time, the outdoor unit does not have frost, which is a case of misdefrosting. ;

[0039] The first preset condition further includes: air relative humidity RH>first preset threshold RH1, outdoor unit coil temperature T<first preset temperature T1, and lasts for more than a second preset time t2.

[0040] The value range of the first preset threshold RH1 is: 65%-7...

Embodiment 2

[0061] A defrosting control device for an air conditioner, comprising:

[0062] A detection unit, the detection unit is used to detect the relative humidity of the air and the temperature of the coil of the outdoor unit;

[0063] A calculation unit, the calculation unit is used to calculate the temperature rise rate of the outdoor unit coil for a period of time;

[0064] A control unit, the control unit is used to adjust the frequency of the compressor to defrost the outdoor unit according to the relative air humidity and the coil temperature of the outdoor unit.

Embodiment 3

[0066] An air conditioner includes the above-mentioned air conditioner defrosting control device.

[0067] The detection unit includes an air relative humidity sensor and an outdoor unit coil temperature sensor;

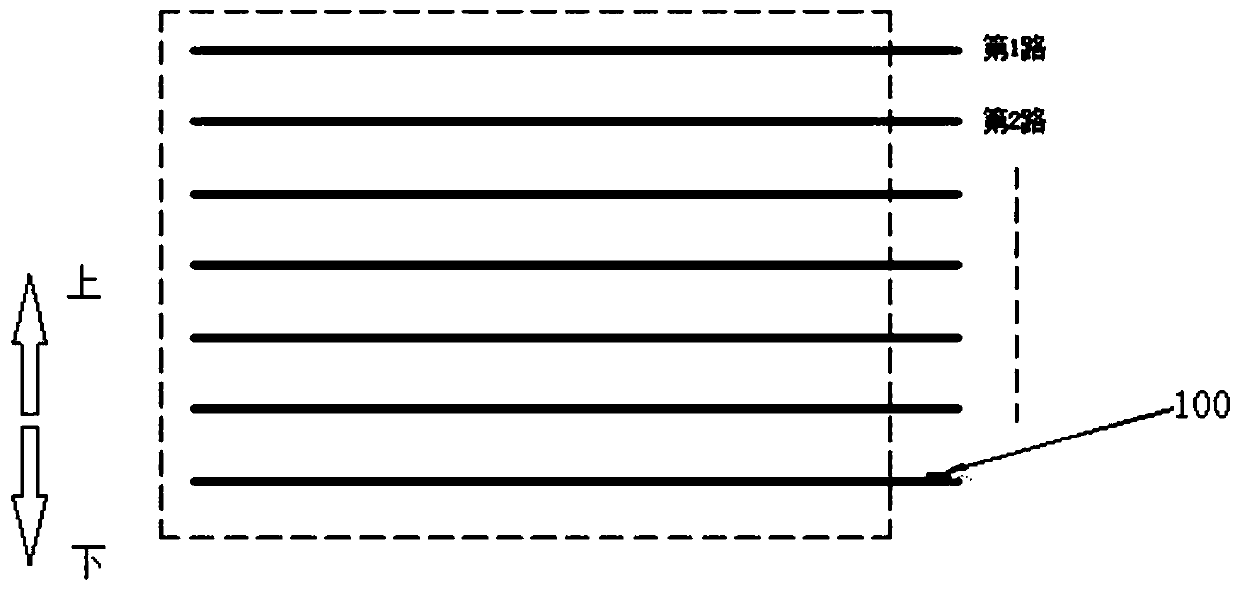

[0068] see image 3 , the outdoor unit coil temperature sensor 100 is located at the outlet of the flow path on the lowermost side of the heat exchanger coil of the outdoor unit, and the frosting condition of this flow path is the most serious;

[0069] see Figure 4 , the relative air humidity sensor 200 is located at the air inlet of the heat exchanger of the outdoor unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com