Heavy-load vehicle tire

A technology of tires and wheels, which is applied to vehicle parts, tire parts, tire treads/tread patterns, etc., and can solve problems such as dangerous stress and tension concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

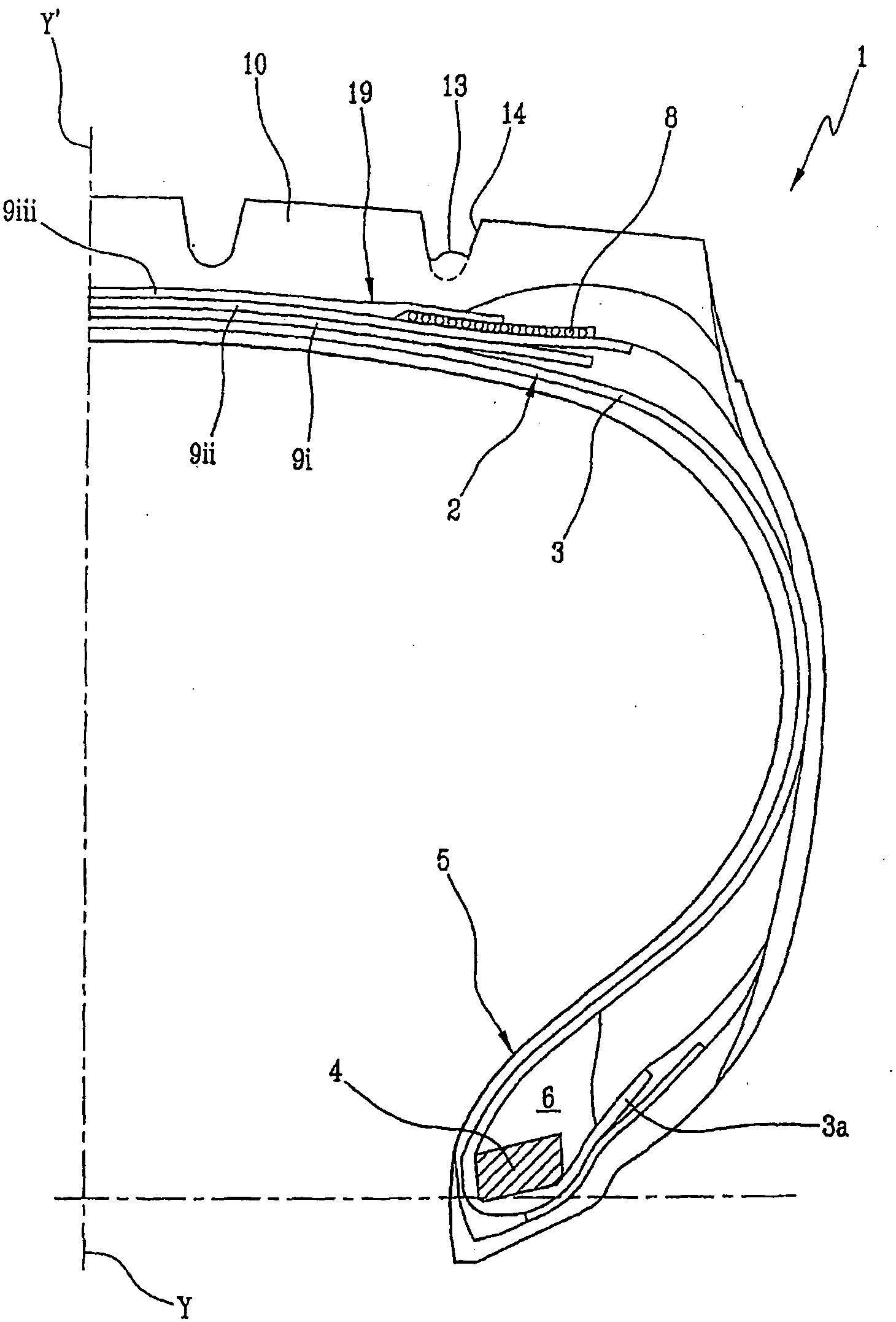

[0076] exist figure 1 Among them, a tire for a wheel according to the invention, in particular a tire to be mounted on a wheel of a heavy-duty vehicle, is indicated generally by reference numeral 1 .

[0077] Throughout the specification and in the following claims, the expression "heavy-duty vehicles" should be understood as referring to the "Classification and definition of power-driven vehicles and trailers", such as trucks, vans, tractors, buses, large vans and other vehicles of this type.

[0078] The tire 1 comprises a carcass structure 2 comprising at least one carcass ply 3 formed of reinforcing cords embedded in an elastomeric matrix.

[0079] The carcass ply 3 has opposite end strips 3 a engaged with respective bead cores 4 . The bead core 4 is located in a region 5 of the tire commonly referred to as the "bead".

[0080] On the peripheral edge of the bead core 4 there is provided an elastomeric filler occupying the space defined between the carcass ply 3 and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap