Tipping system of dual-purpose foldback tippler and use method thereof

A dumper and switchback technology, which is applied in the field of switchback dumper dumping system, can solve the problems of high production cost, inability to dump and unload gondola cars at the same time, and low production cost of occupied area, so as to achieve high dumping efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

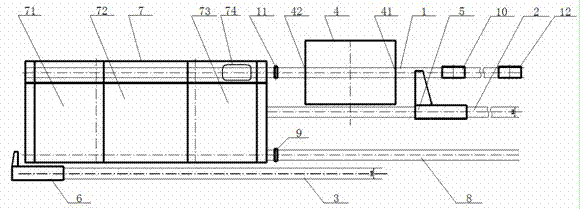

[0033] In the present invention, the dumping steps of the single-section uncoiled gondola car are as follows: first, the single-section decoupling gondola car manually decoupled is drawn to the dumper 4 by the heavy vehicle shunting machine 5, and after the dumping operation, the dumped empty car is then dumped. The gondola car is pushed to the moving car platform 7. When there are two dumped gondola cars parked on the car moving platform 7, the car moving platform 7 moves the two empty gondola cars to the empty car line 8, and then the air-conditioned car track 3 The empty car shunting machine 6 on the top pushes the two empty cars on the car moving platform 7 through the No. 1 stopper 9 and returns. At the same time, the car moving platform 7 returns to the heavy car line 1, repeating the above process, and the cycle operation .

Embodiment 2

[0035] In the present invention, the dumping steps of a group of three-section gondola wagons are as follows:

[0036] The first step: First, the whole row of C80 gondola cars in groups of three are pulled by the heavy car shunting machine 5 to move forward along the heavy car line 1. When the fourth gondola car reaches the far-end wheel holder 12, the third and fourth sections The couplers in between are manually decoupled, and then the fourth section of the open car is fixed by the far-end wheel gripper 12, and then the heavy vehicle shunting machine 5 is used to pull and push the first three open car to continue along the heavy vehicle line 1;

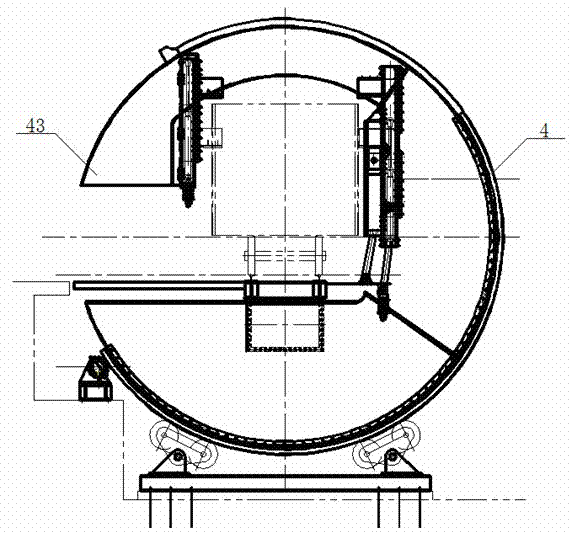

[0037] Second step: when the first gondola car enters the dumper 4, the second gondola car is first fixed by the near-end wheel gripper 10, and then the first gondola car is dumped by the dumper 4 without decoupling;

[0038] Step 3: After the dumping of the above-mentioned first section of the gondola car is completed, first open t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com