Sweeper with following garbage can

A dustbin and sweeper technology, which is applied in road cleaning, construction, cleaning methods, etc., can solve the problems of restricting the continuation distance and working efficiency of sweeping machines, increasing the labor intensity of operators, and increasing the turning radius, etc., to achieve structural Simple, easy to make, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

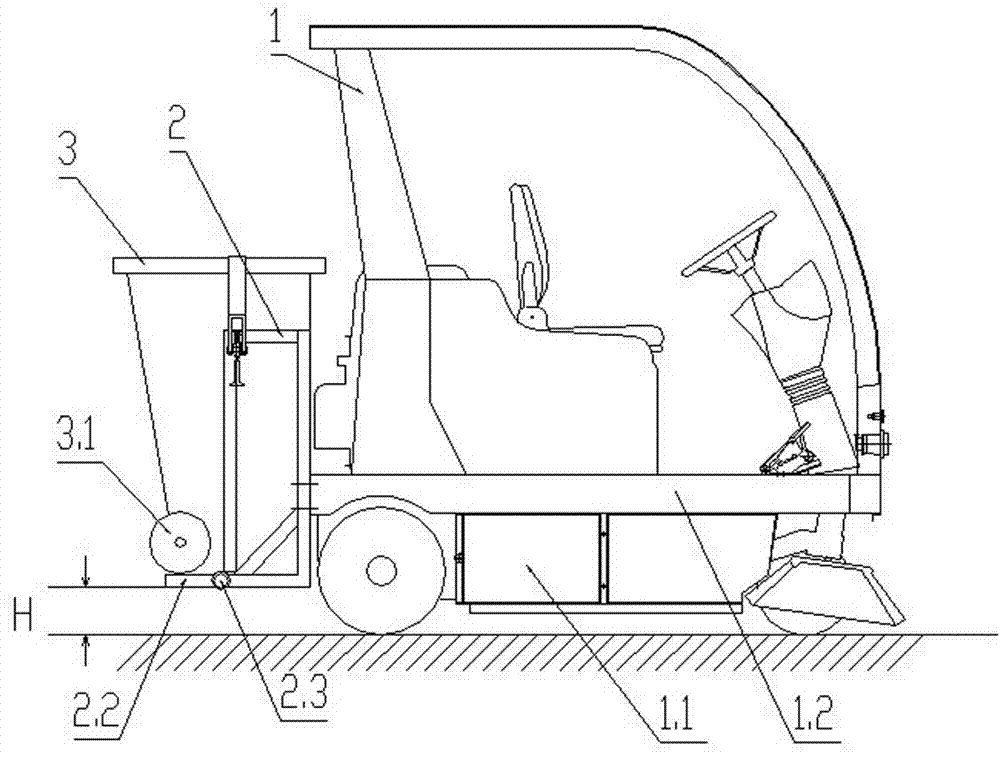

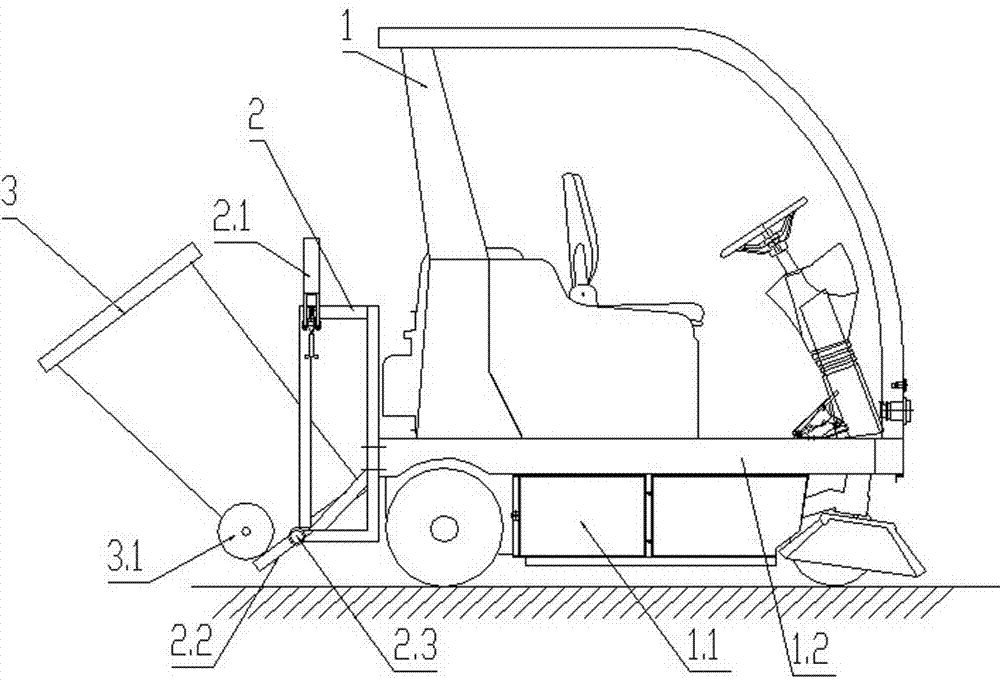

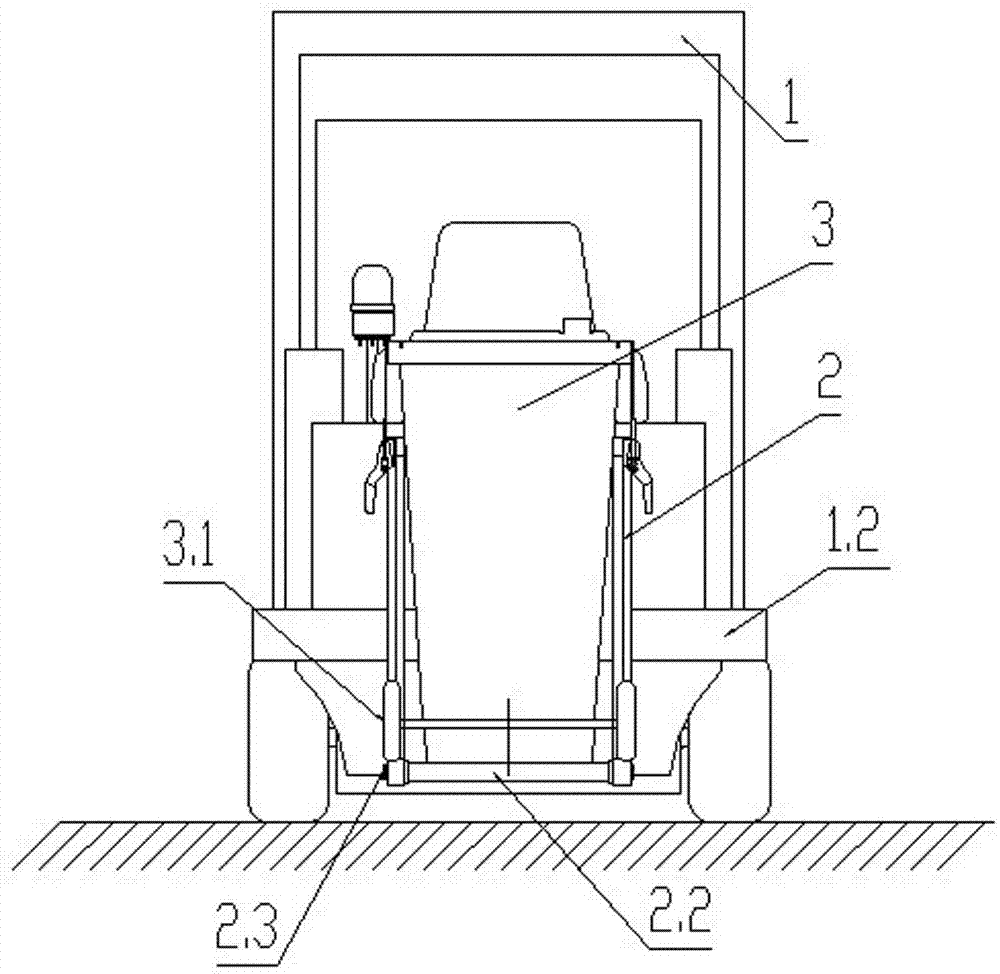

[0018] figure 1 Shown is an embodiment of a sweeper with accompanying garbage bins, which includes a sweeper 1 , a frame 2 and a dustbin 3 . The vehicle-mounted garbage box 1.1 of the sweeper 1 is a side-opening structure, which enables barrier-free loading and unloading of the vehicle-mounted garbage box 1.1, greatly improving the efficiency of dumping garbage. The frame 2 is an upright rectangular body for placing the dustbin 3. In order to facilitate the loading and unloading of the dustbin 3, the frame 2 adopts an open structure towards the back and the top surface, and the bottom is provided with a supporting plate 2.2, and the upper parts of the mullions on both sides are installed and tightened. Buckle 2.1. Both sides of the supporting plate 2.2 are hinged with the frame 2 through the coaxial pin shaft 2.3 to form an outward flip structure. The hinge connection point is located at the end of the frame at the bottom of the frame 2 facing backward. When the supporting pl...

Embodiment 2

[0020] This embodiment 2 is a sweeper with a width of 2000mm and a self-provided accompanying garbage bin. Because the sweeper 1 has a larger specification and its own weight is greater than that of embodiment 1, the height of the bottom plane of the frame 2 from the ground is H=180mm. This size ensures that the frame 2 The bottom and the rollers 3.1 are not in contact with the ground, and the lower installation height is convenient for loading and unloading of the dustbin 3 . In this embodiment, except that the suspension height of the frame 2 is slightly different from that of Embodiment 1, the rest of the structure is exactly the same as that of Embodiment 1, and the technical effect of implementation is also the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com