Automatic charger for lithium battery cluster

An automatic charging device, lithium battery technology, applied in battery circuit devices, circuit devices, electric vehicles, etc., can solve the problems of wasting manpower and material resources, inconvenient operation, etc., and achieve the reduction of occupied manpower, the improvement of automation, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

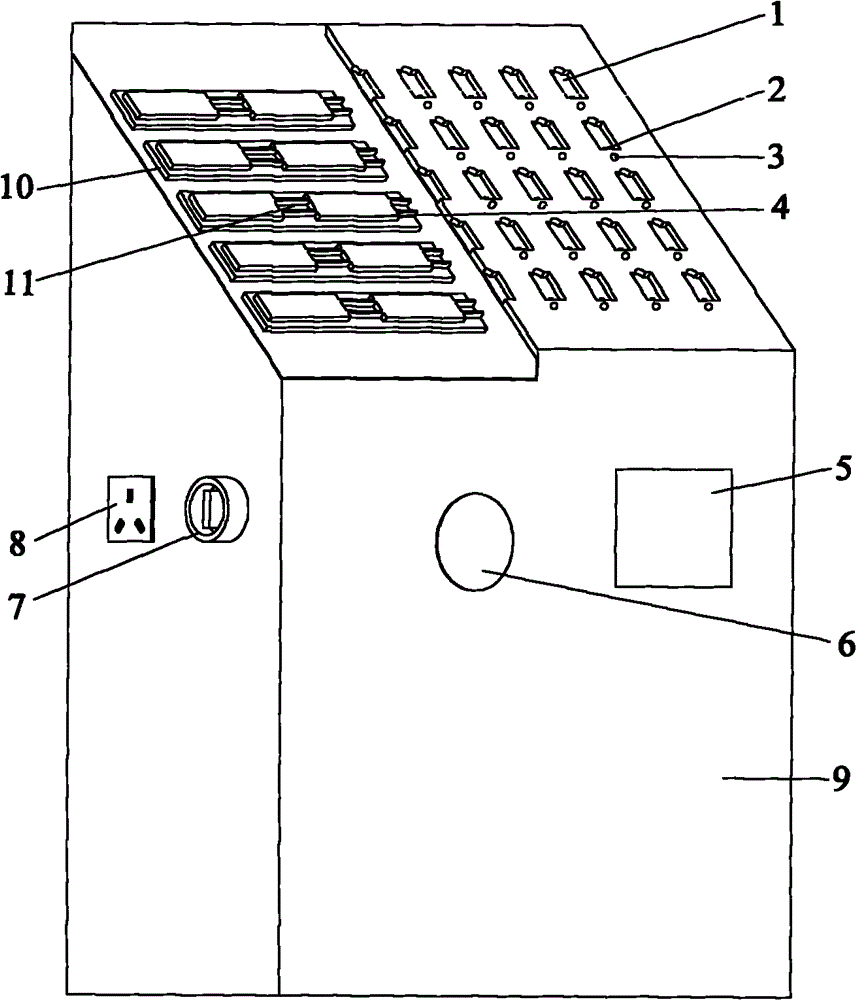

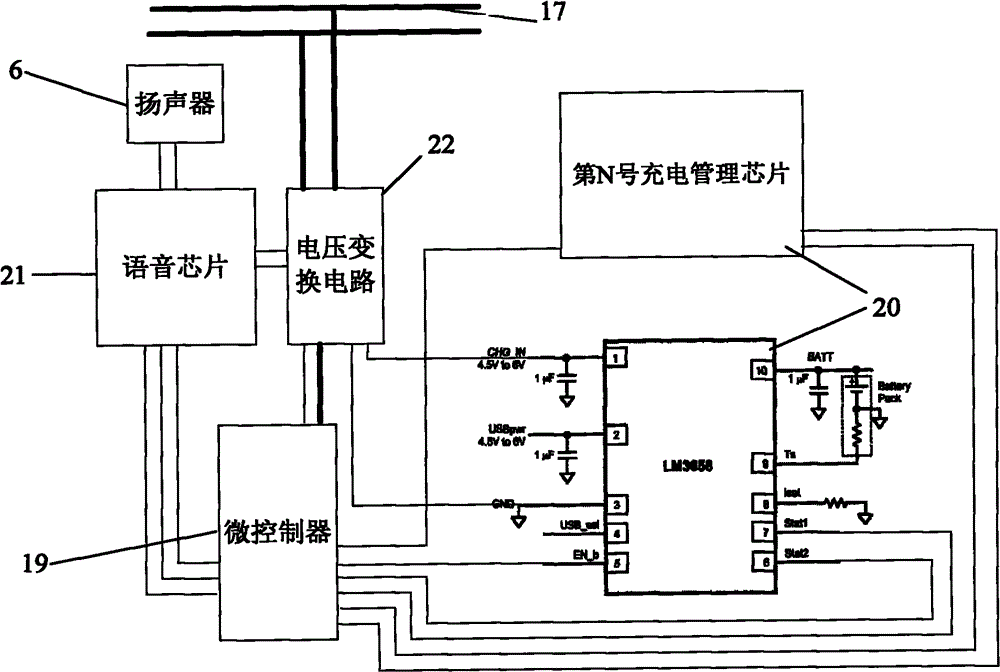

[0019] The invention provides a charging device with on-line measurement and control of the charging state by a single-chip computer, automatic power-off after charging, and sound and light prompts.

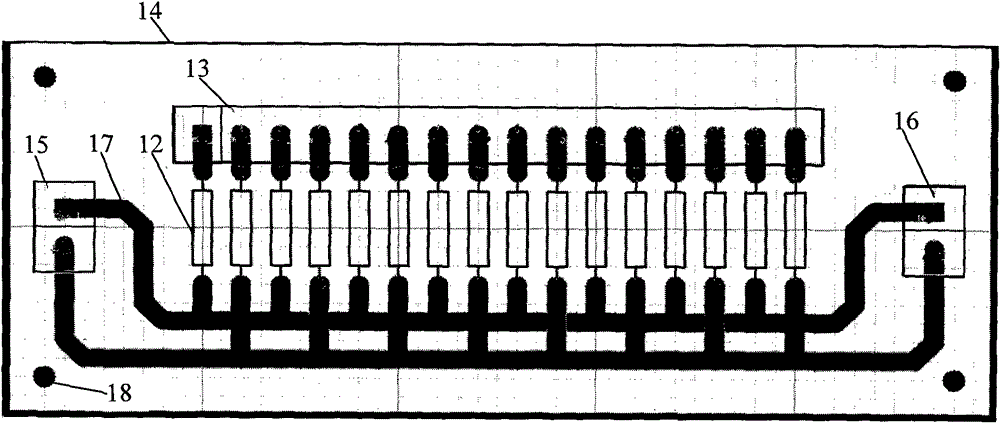

[0020] Such as figure 1 As shown, the lithium battery cluster type automatic charging device includes a box body 9 and a charging management circuit. The upper panel of the box body 9 is embedded with a plurality of charging grooves 1 for placing lithium batteries, and one side of each charging groove 1 is set There are fixed metal contacts 2, and the three metal contacts correspond to an interface, which is used for power supply and charging measurement and control of lithium batteries; an indicator light 3 is provided on the periphery of each charging groove; a power hub is installed on the middle bracket panel of the box 4. The charging management circuit 5 and the speaker 6 are installed on the side panel of the box body, the charging management circuit 5 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com