Arm mechanism and vacuum robot with the mechanism

An arm mechanism and robot technology, applied in the field of robotics, can solve problems such as increased arm mass, limited arm telescopic range, excessively enlarged arm base, etc., to achieve the effect of improving transmission rigidity, safe wiring, and maintaining a good linear trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

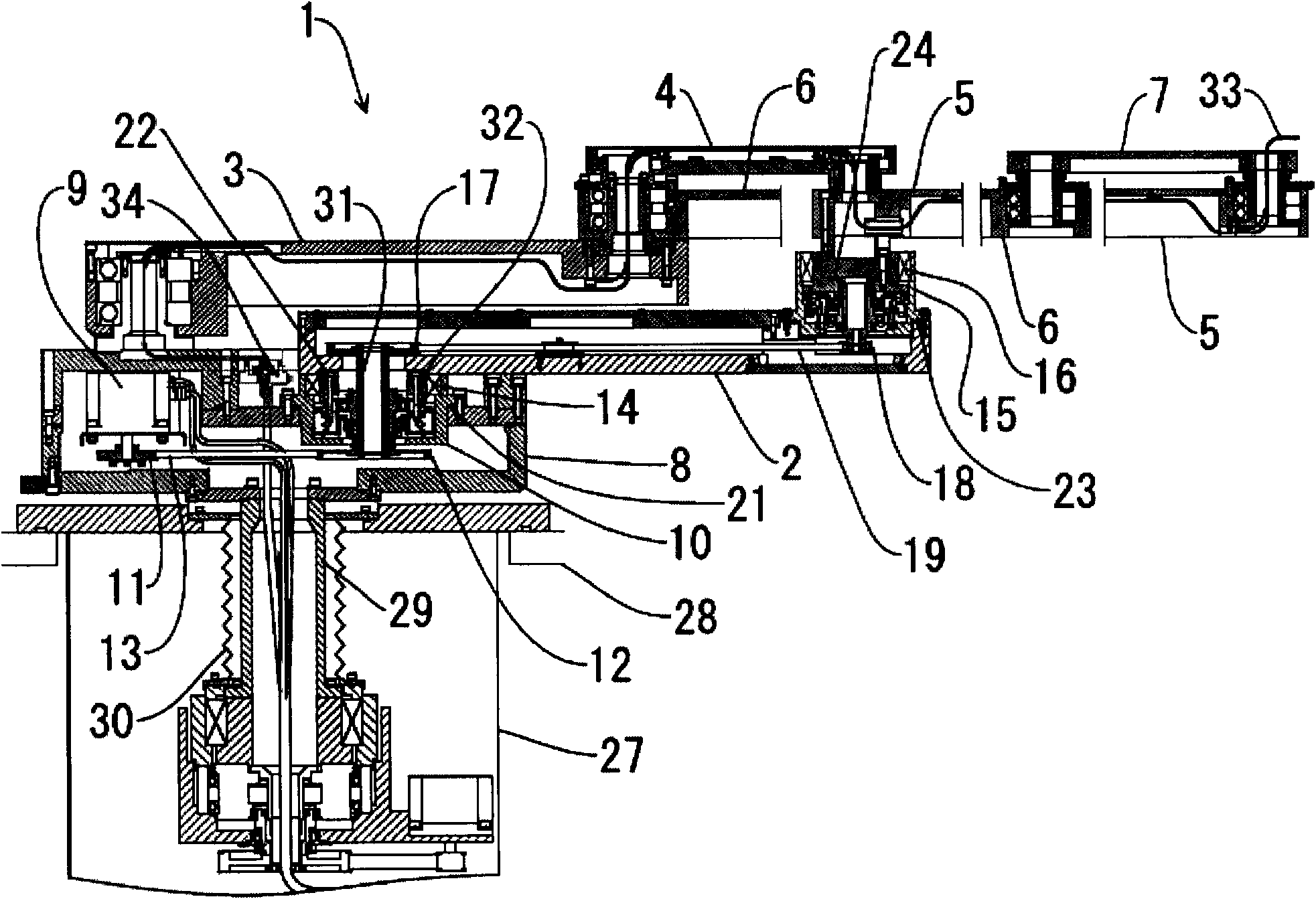

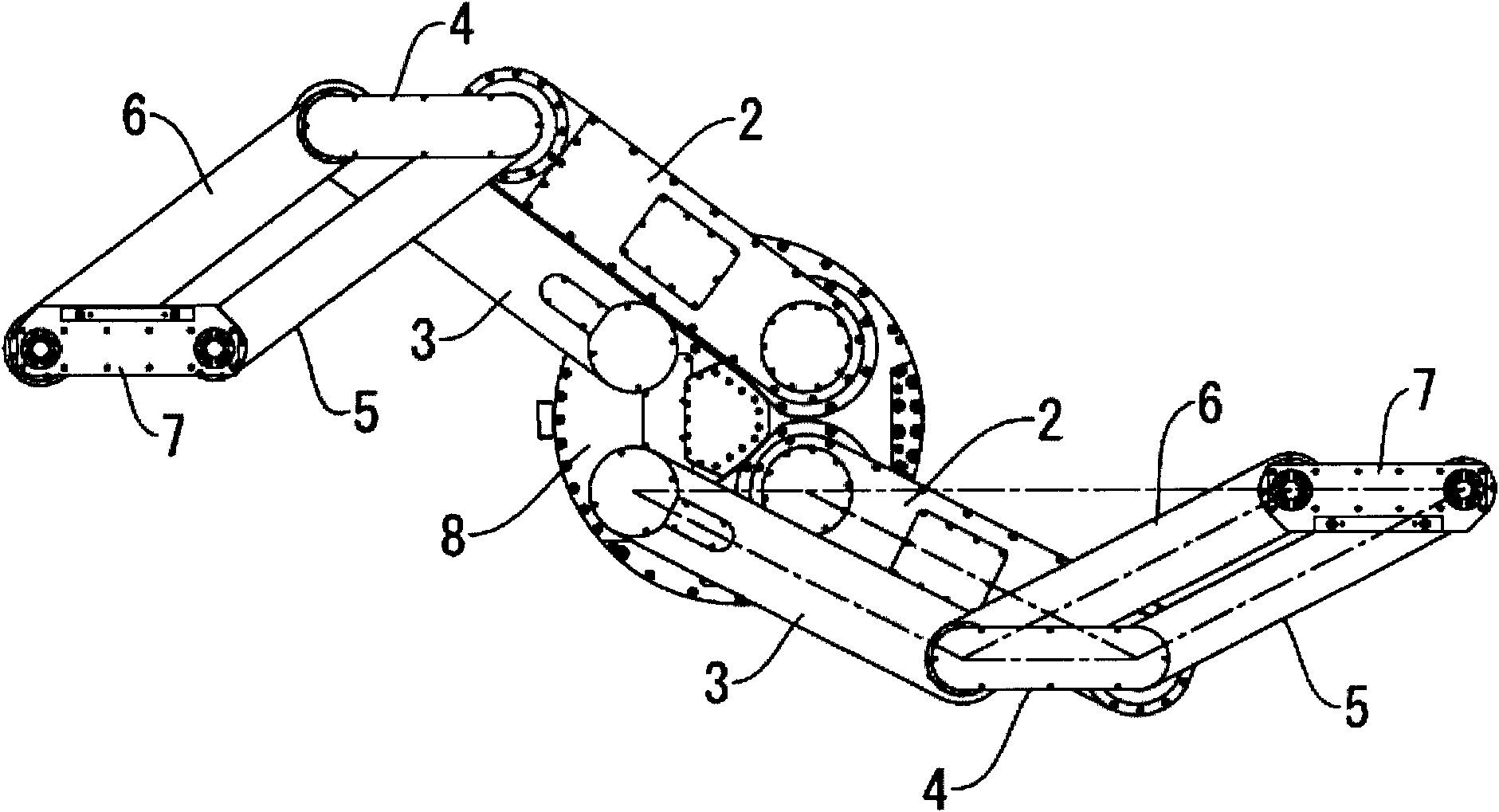

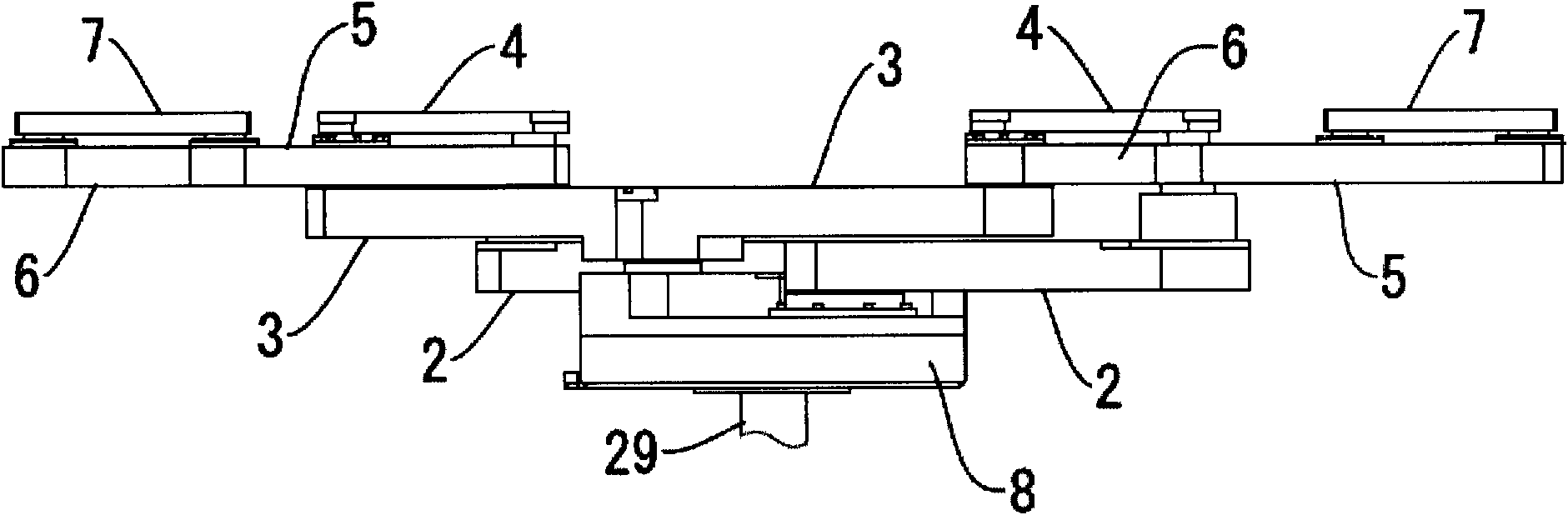

[0039] figure 1 An embodiment of the present invention is shown, and it is a side sectional view showing mainly the arm portion of the vacuum robot. and, figure 2 Yes figure 1 top view. and, image 3 Yes figure 1 side view of the exterior. like figure 2 As shown, in the present embodiment, a so-called dual-arm vacuum robot having two arms is shown. However, as described below, there is no problem even with a one-arm vacuum robot. In addition, since each of the two arms has the same structure, the following basis figure 1 and figure 2 Only the structure of any one arm will be described.

[0040] The arm roughly includes: a first arm 2 that can be rotated on an arm base 8 described later; a second arm 5 that can be rotated on the front end of the first arm 2; and a first link 3 that can be rotated on the arm base 8 The front end is rotatably connected to the front end of the first arm 2 through the first connecting link 4; the base end of the second link 6 is rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com