Bonding device

一种焊接装置、焊接工具的技术,应用在焊接设备、非电焊设备、电气元件等方向,能够解决维修保养化费时间、不能检测毛细管前端振动变化、焊接性能影响等问题,达到简单构成的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

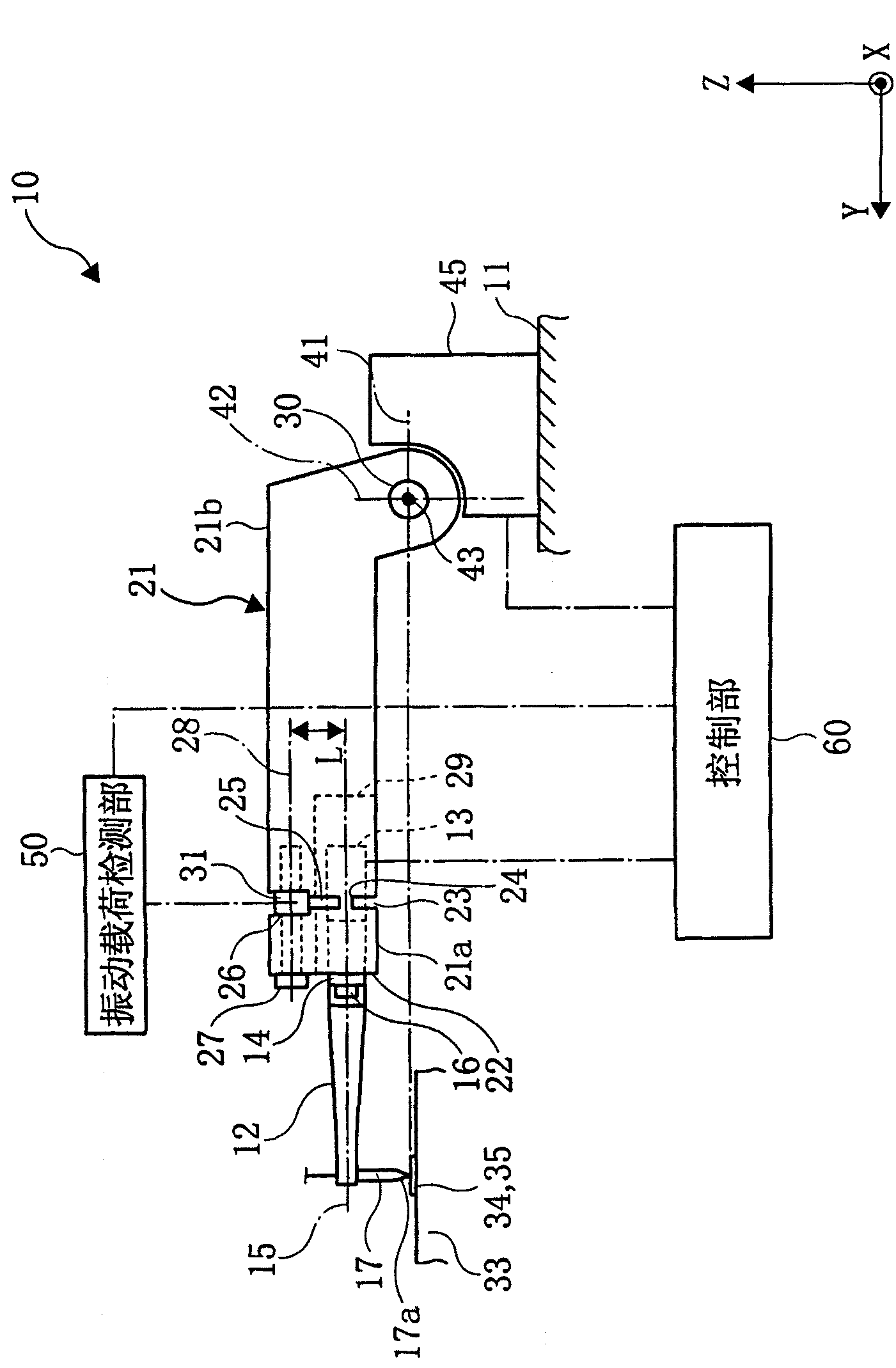

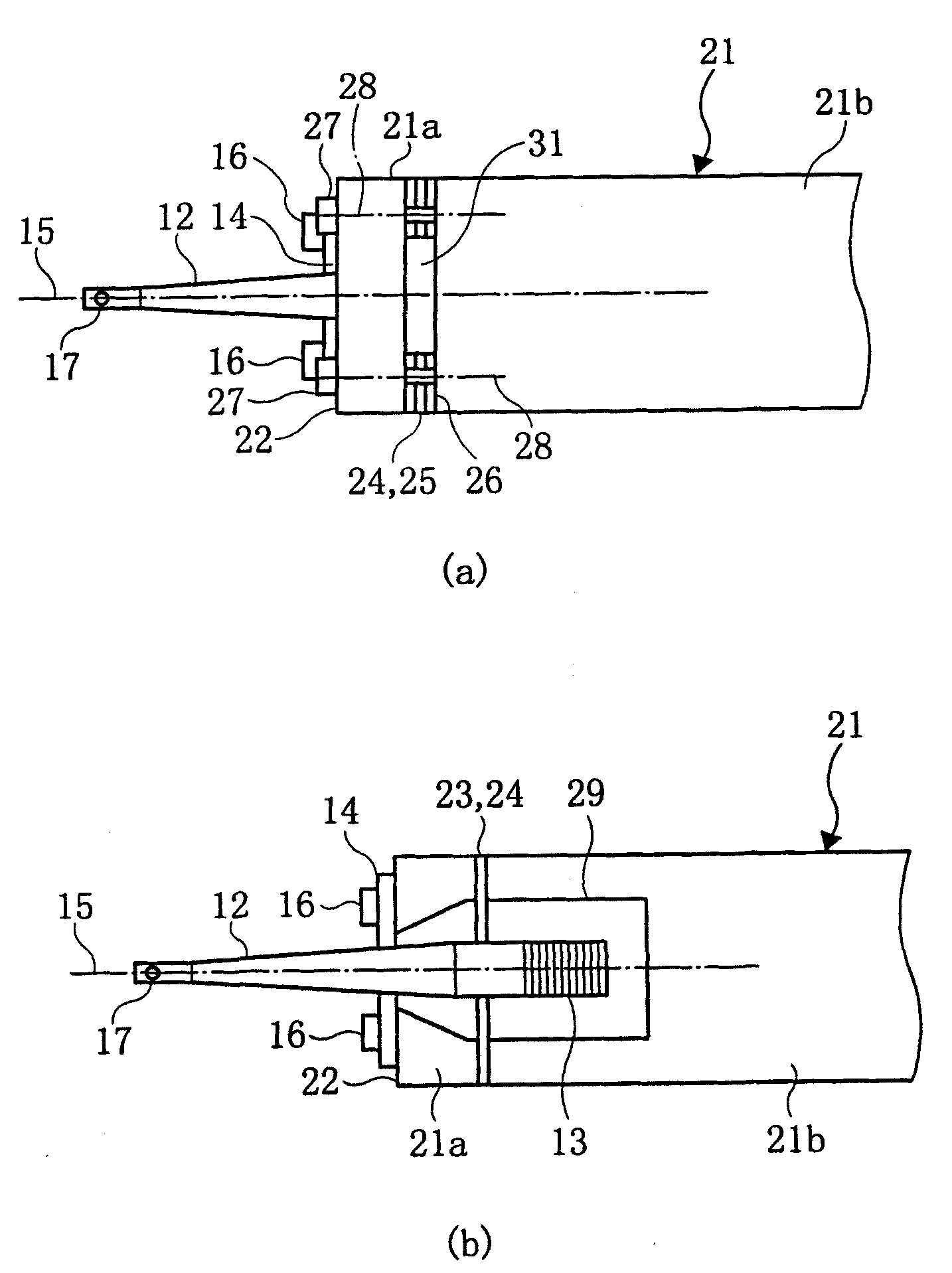

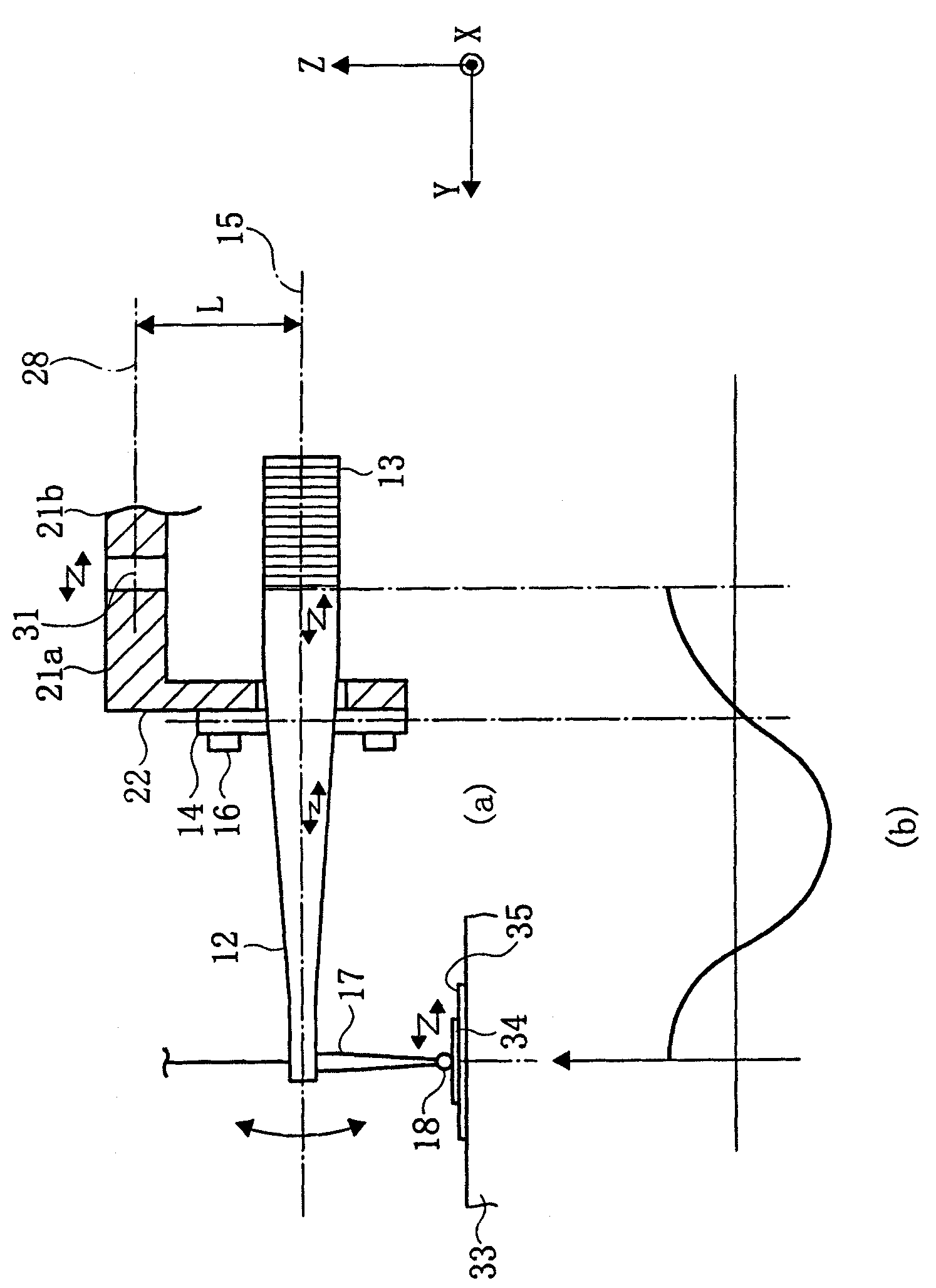

[0062] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 As shown, the wire bonding device 10 of this embodiment includes a bonding head 11 as a base, an ultrasonic vibrator 13, an ultrasonic mold 12, a capillary 17 as a bonding tool, a flange 14 provided on the ultrasonic mold 12, a welding arm 21, and a load. The sensor 31 , the drive motor 45 , the vibration load detection unit 50 , the control unit 60 , and the soldering table 33 that absorb and fix the semiconductor chip 34 and the substrate 35 to be soldered.

[0063] A driving motor 45 for driving the welding arm 21 to rotate is provided on the welding head 11 . The ultrasonic vibrator 13 is formed by stacking a plurality of piezoelectric elements, and is mounted on the rear end side of the ultrasonic mold 12 . Also, a capillary 17 is attached to the tip of the ultrasonic mold 12 . The flange 14 is provided at a position to be a vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com