Connection assembly for fastening an attachment element to a support

A technology for connecting components and connectors, applied in the direction of connecting components, fasteners, applications, etc., can solve the problems of time-consuming installation and disassembly, and achieve the effect of avoiding wrong installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

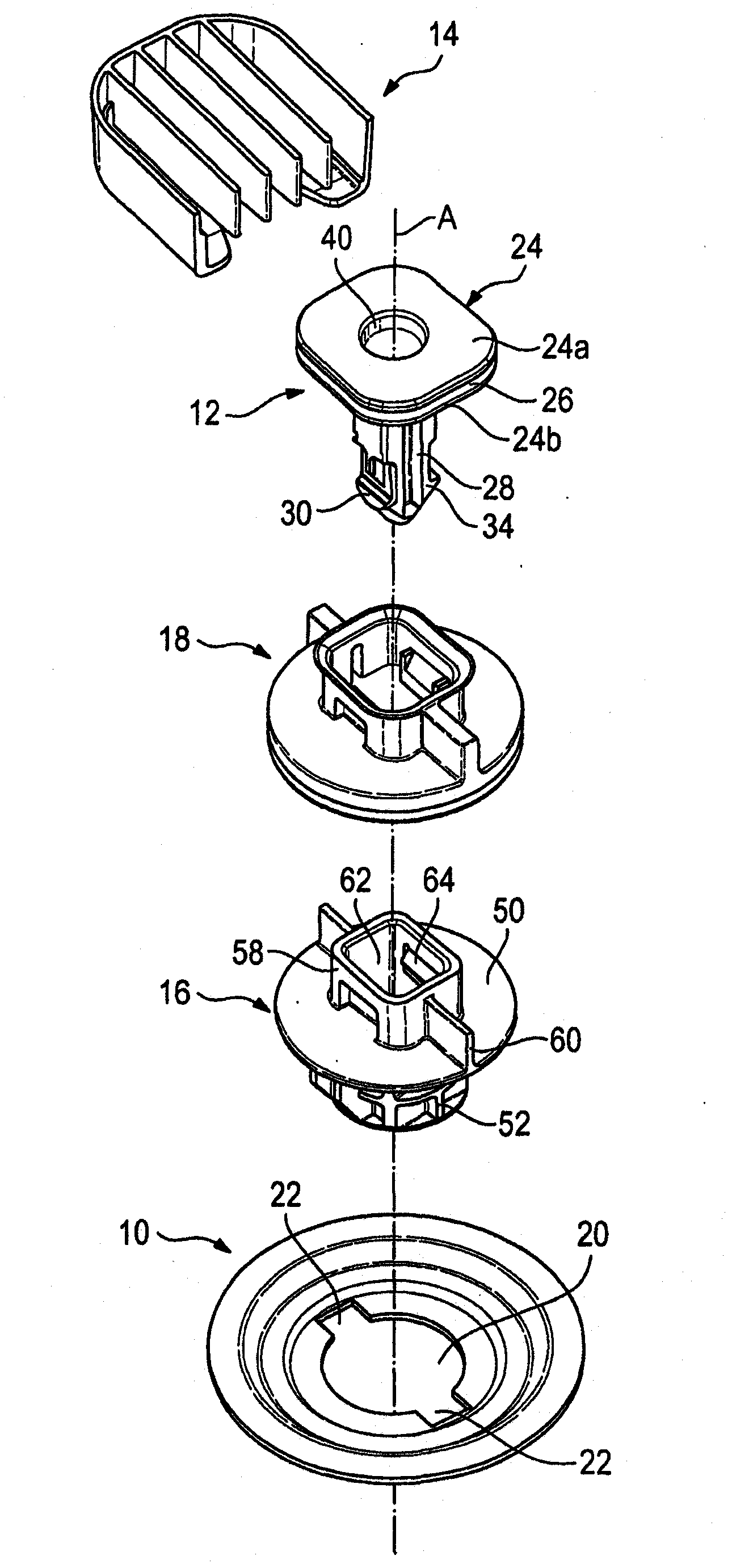

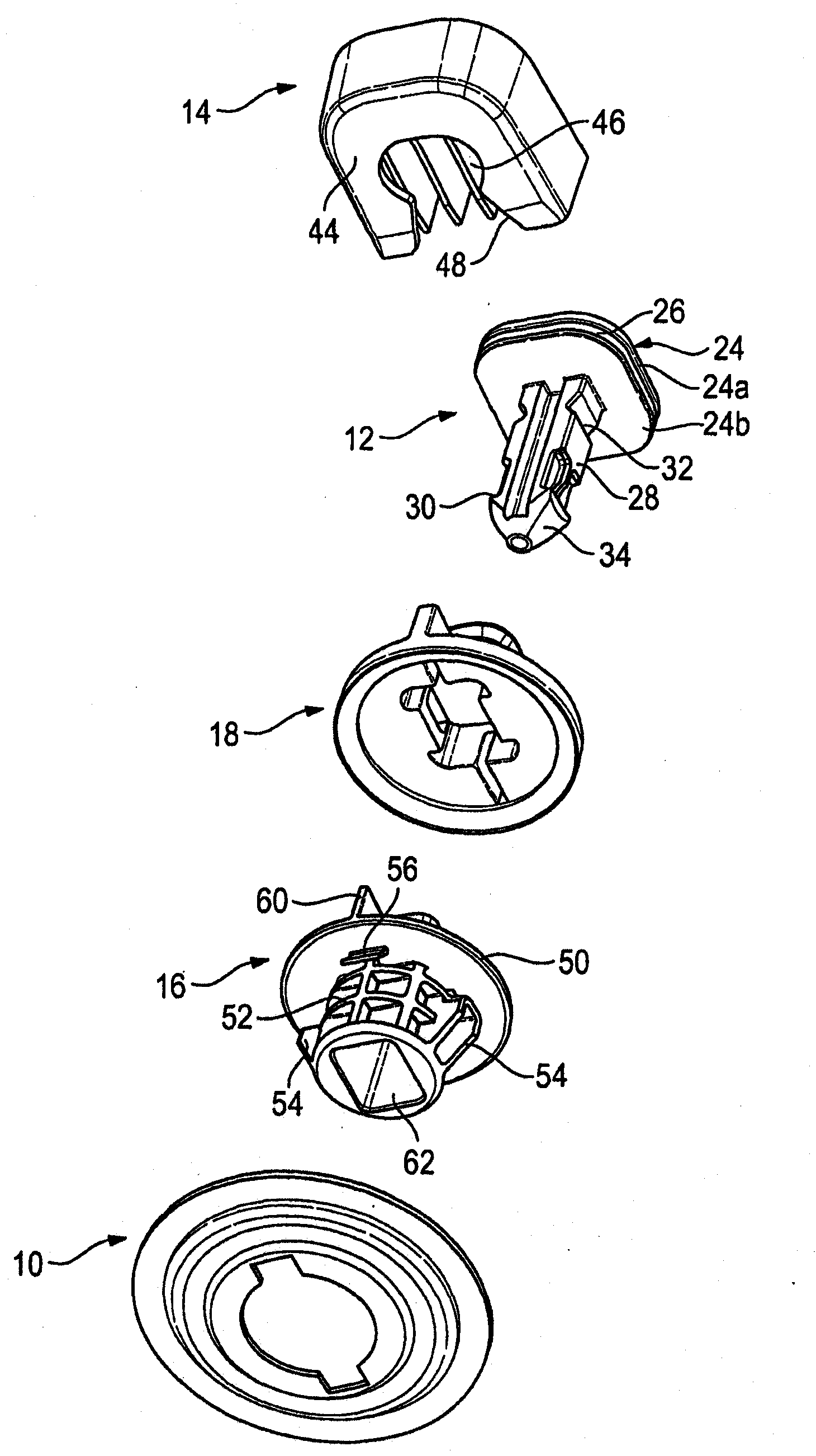

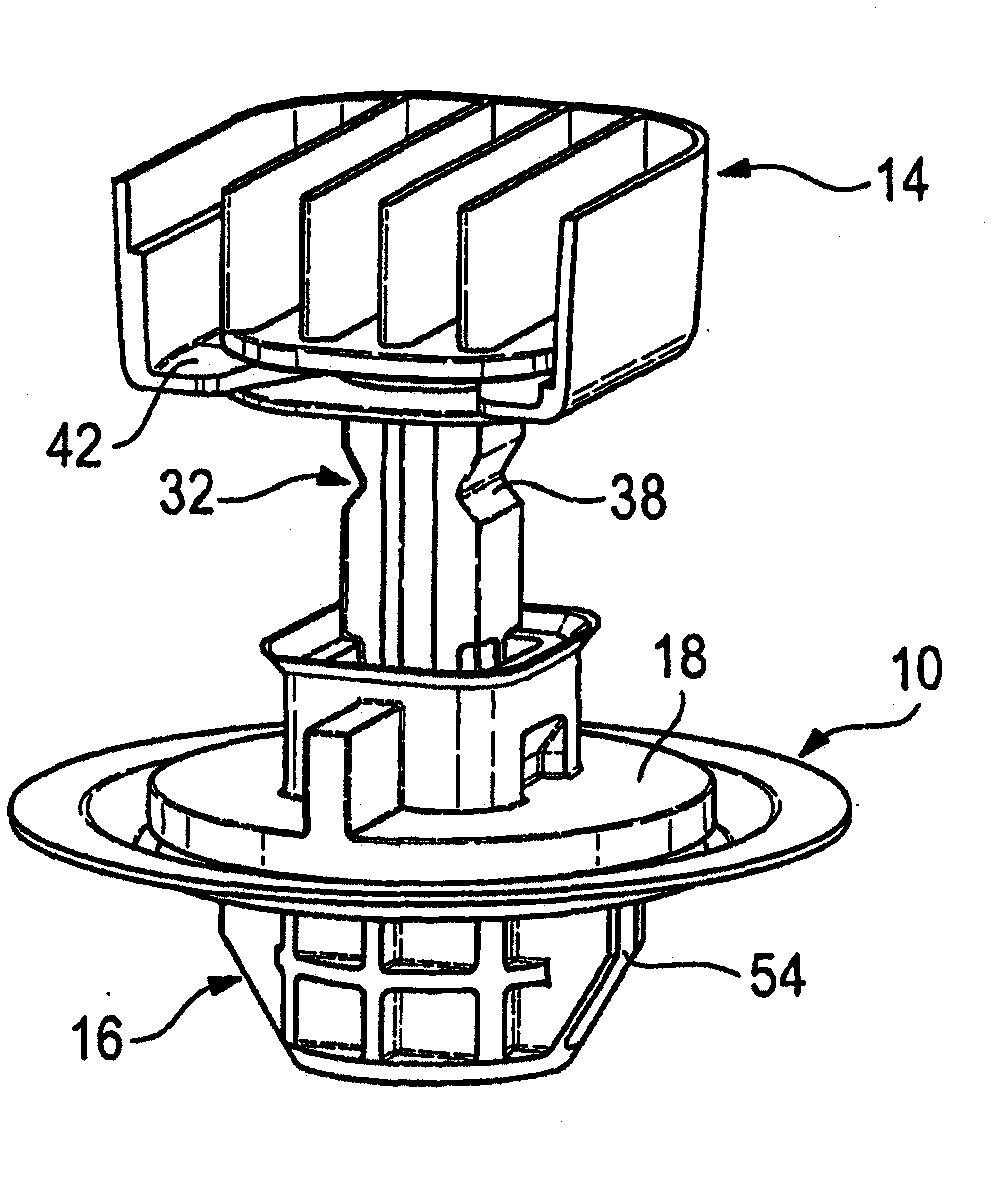

[0021] figure 1 and 2 The components of the connection assembly for securing the attachment to the stand 10 are shown separately. In this case, the orientation of the individual components corresponds to the orientation in the installed state of the connection assembly. The structure of each component and its cooperating effect are described below with the fixing of the door lining of a motor vehicle on the door panel as an example. However, the invention is not limited to this application, but can also be used for other purposes.

[0022] The connection assembly comprises a pin 12 made of hard plastic, preferably POM-C (polyoxymethylene copolymer), a connecting piece 14 (stopper), made of hard plastic, preferably PBT GF (glass-fiber-reinforced polyethylene terephthalate) Butylene formate) retaining clip 16 and optionally a seal 18 made of elastic plastic, preferably TPE-V (thermoplastic elastomer vulcanizate). The connecting assembly is designed to connect an attachment (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com