Crankcase ventilation rubber hose and machining method thereof

A crankcase ventilation and rubber tube technology, applied in the rubber tube field, can solve the problems of low aging performance and difficult to achieve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

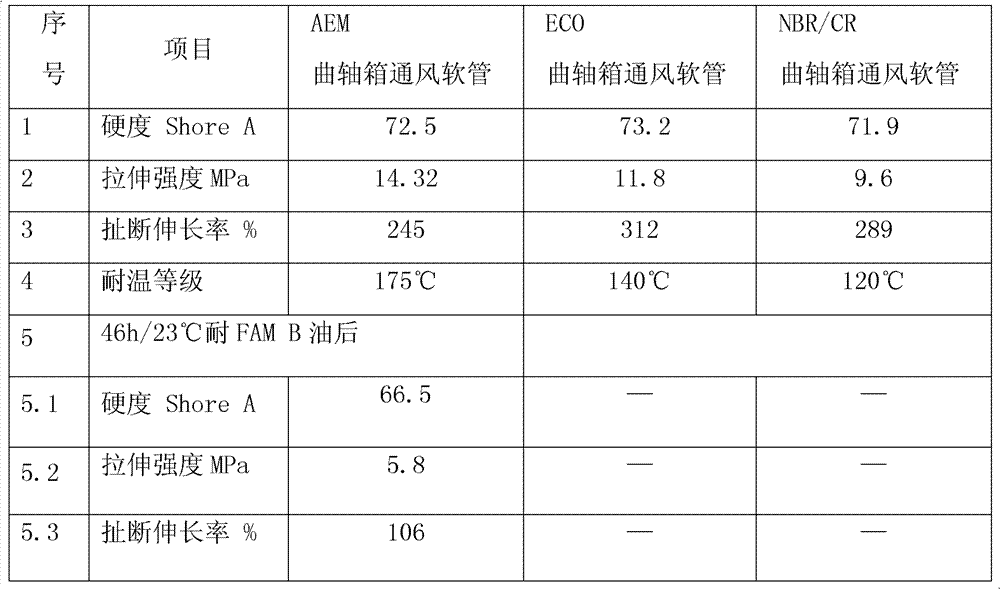

Embodiment 1

[0031] 1. Formula (by parts by mass)

[0032] Raw rubber GLS 60 servings

[0033] Raw rubber ER 30 parts,

[0034] 10 parts raw rubber NBR,

[0035] 60 parts of reinforcing agent carbon black,

[0036] Plasticizer TP-759 5 parts,

[0037] Internal mold release agent Vanfre VAM 0.5 parts,

[0038] Antiager Naugard 445 2 parts,

[0039] Vulcanizing agent Diak 1# 1 part,

[0040] Accelerator DOTG 1 part

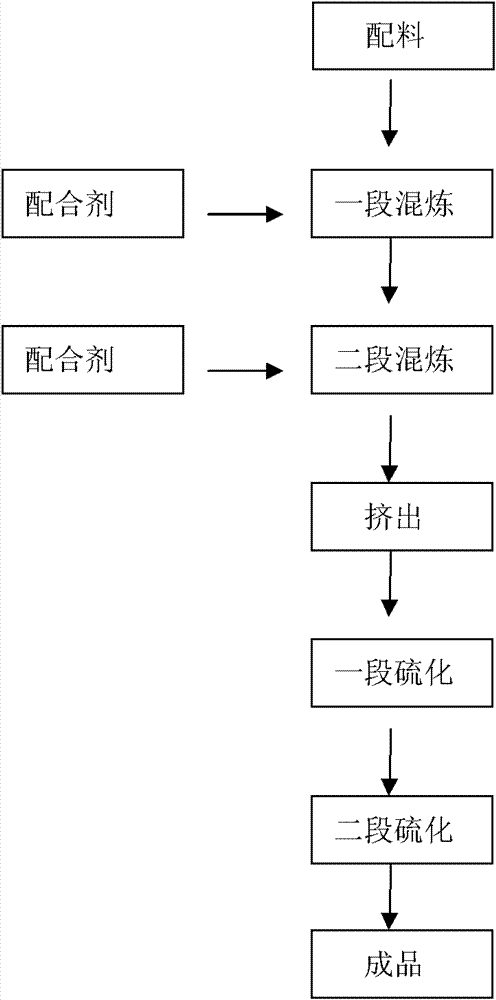

[0041] 2. Preparation method

[0042] As shown in the accompanying drawings, specific examples are as follows:

[0043] 1) Ingredients

[0044] According to the mass parts specified in the rubber formula, all rubber and corresponding small auxiliary materials are batched, and the reinforcing agent and plasticizer are automatically fed by the pipeline automatic conveying system.

[0045] 2) Rubber mixing

[0046]It is produced by the two-stage rubber mixing process of the internal mixer to ensure that the rubber material has a bright appearance after mixing and the r...

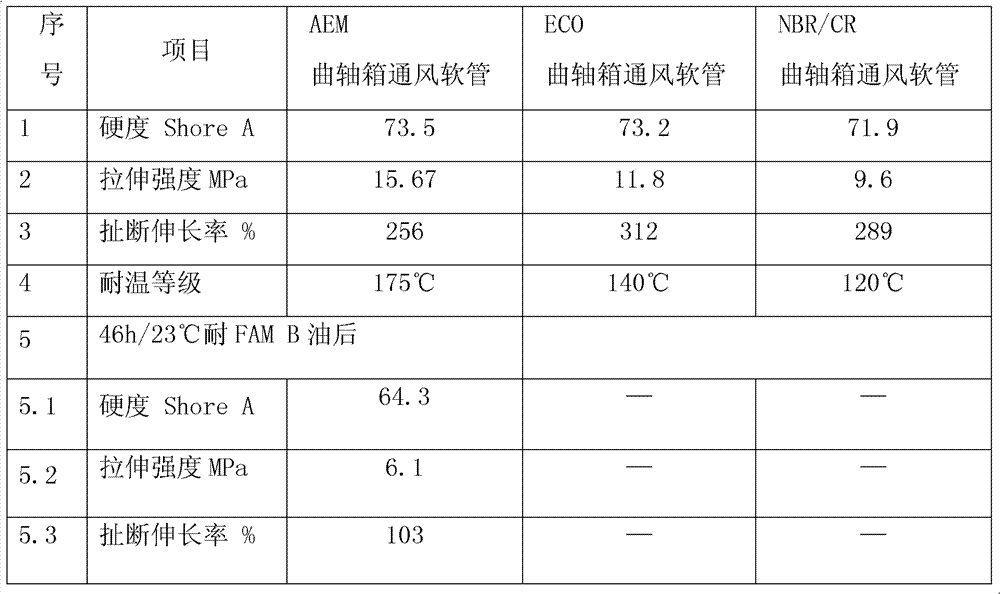

Embodiment 2

[0056] 1. Formula (by parts by mass)

[0057] Raw rubber GLS 60 servings

[0058] Raw rubber ER 30 parts,

[0059] 10 parts raw rubber NBR,

[0060] 70 parts of reinforcing agent carbon black,

[0061] Plasticizer ADB-30 10 parts,

[0062] Internal mold release agent WS180 1.0 parts,

[0063] Antiager Naugard 445 2.0 parts,

[0064] Vulcanizing agent Diak 1# 1.5 parts,

[0065] Accelerator DPG 2.0 parts

[0066] 2. Preparation method

[0067] 1) Ingredients

[0068] According to the mass parts specified in the rubber formula, all rubber and corresponding small auxiliary materials are batched, and the reinforcing agent and plasticizer are automatically fed by the pipeline automatic conveying system.

[0069] 2) Rubber mixing

[0070] It is produced by the two-stage rubber mixing process of the internal mixer to ensure that the rubber material has a bright appearance after mixing and the rubber material is evenly mixed.

[0071] One-stage mixing: first put the raw r...

Embodiment 3

[0080] 1. Formula (by parts by mass)

[0081] Raw rubber GLS 60 servings

[0082] Raw rubber ER 30 parts,

[0083] 10 parts raw rubber NBR,

[0084] 80 parts of reinforcing agent carbon black,

[0085] Plasticizer TP-95 15 parts,

[0086] Internal mold release agent WB222 1.0 parts,

[0087] Antiager Naugard 445 2 parts,

[0088] Vulcanizing agent Diak 1# 2 parts,

[0089] Accelerator DPG 4 parts,

[0090] 2. Preparation method

[0091] 1) Ingredients

[0092] According to the mass parts specified in the rubber formula, all rubber and corresponding small auxiliary materials are batched, and the reinforcing agent and plasticizer are automatically fed by the pipeline automatic conveying system.

[0093] 2) Rubber mixing

[0094] It is produced by the two-stage rubber mixing process of the internal mixer to ensure that the rubber material has a bright appearance after mixing and the rubber material is evenly mixed.

[0095] One-stage mixing: first put the raw rubber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com