Brake rubber recipe and its processing method

A brake and rubber technology, applied in the direction of brake parts, etc., can solve the problems of difficult to guarantee temperature reliability, limited thickness of heat insulation layer, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

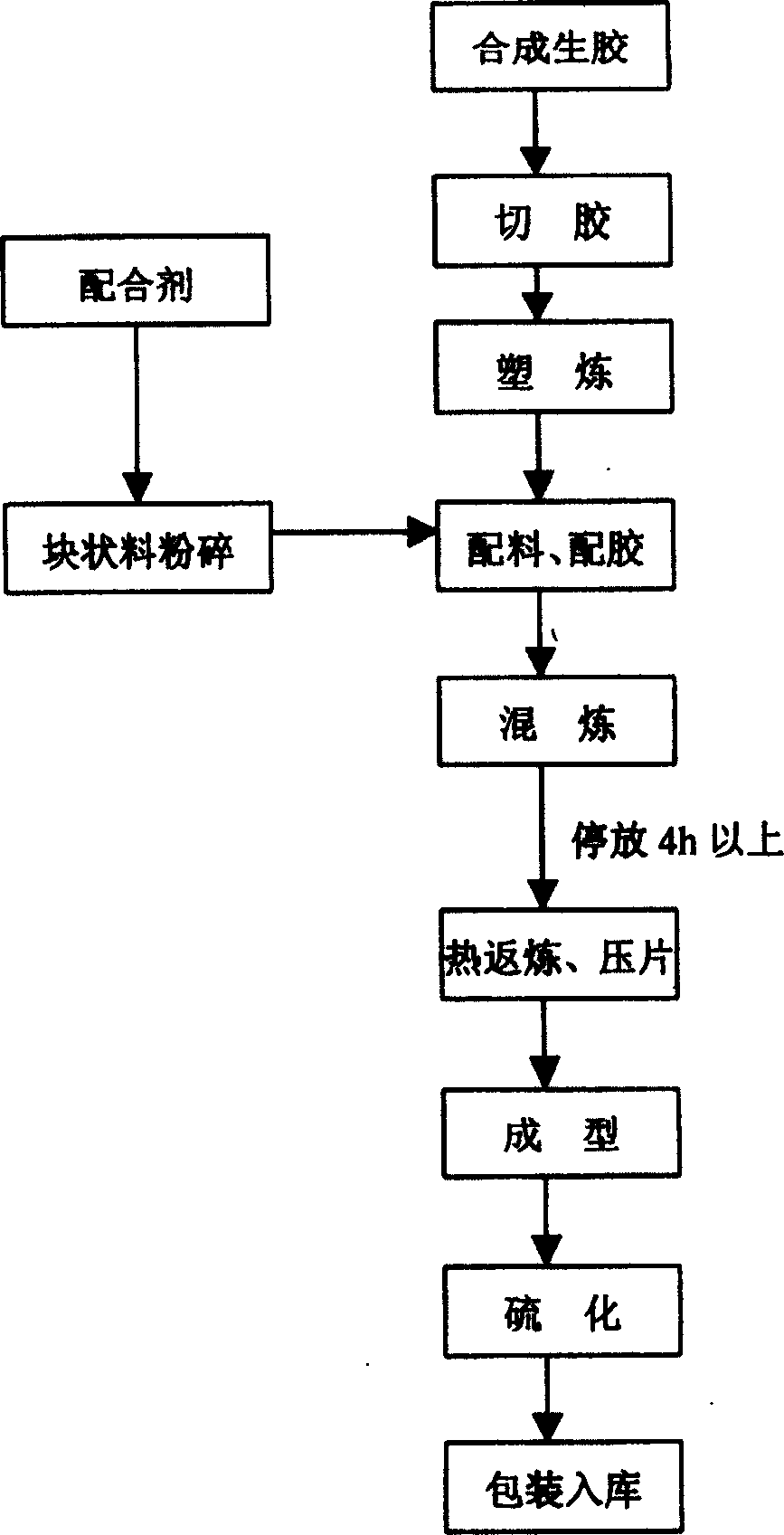

[0024] As shown in the accompanying drawing, the specific process is as follows:

[0025] 1) Raw rubber mastication: In order to properly improve the plasticity of raw rubber, use an open rubber mixer with low roll temperature and variable roll distance (5-8mm to 1-1.5mm) to carry out mastication;

[0026] 2) Batching: crush the raw material components in the rubber formula other than synthetic raw rubber, that is, the compounding agent, and then mix with the raw rubber after mastication according to the mass parts specified in the rubber formula. glue;

[0027] 3) Mixing: use an open mixer for mixing, and the temperature of the mixing drum is always controlled at 50-60°C;

[0028] First, widen the roller pitch of the mixer to 5-8 mm, add the masticated raw rubber, active agent, vulcanizing agent and anti-aging agent in step 1) and knead for 4 minutes; then add reinforcing filler, tackifier, hardener, etc. Mix fatty acid for 8 minutes; then add plasticizer and mix for 1 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com