Tow arm of paver capable of adjusting angle and paver

A paver and angle adjustment technology, which is applied in roads, construction, road repair, etc., can solve the problems of screed design and installation troubles, and achieve the effects of convenient adjustment, labor-saving reduction of mechanical failure points, and simplified structure and installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

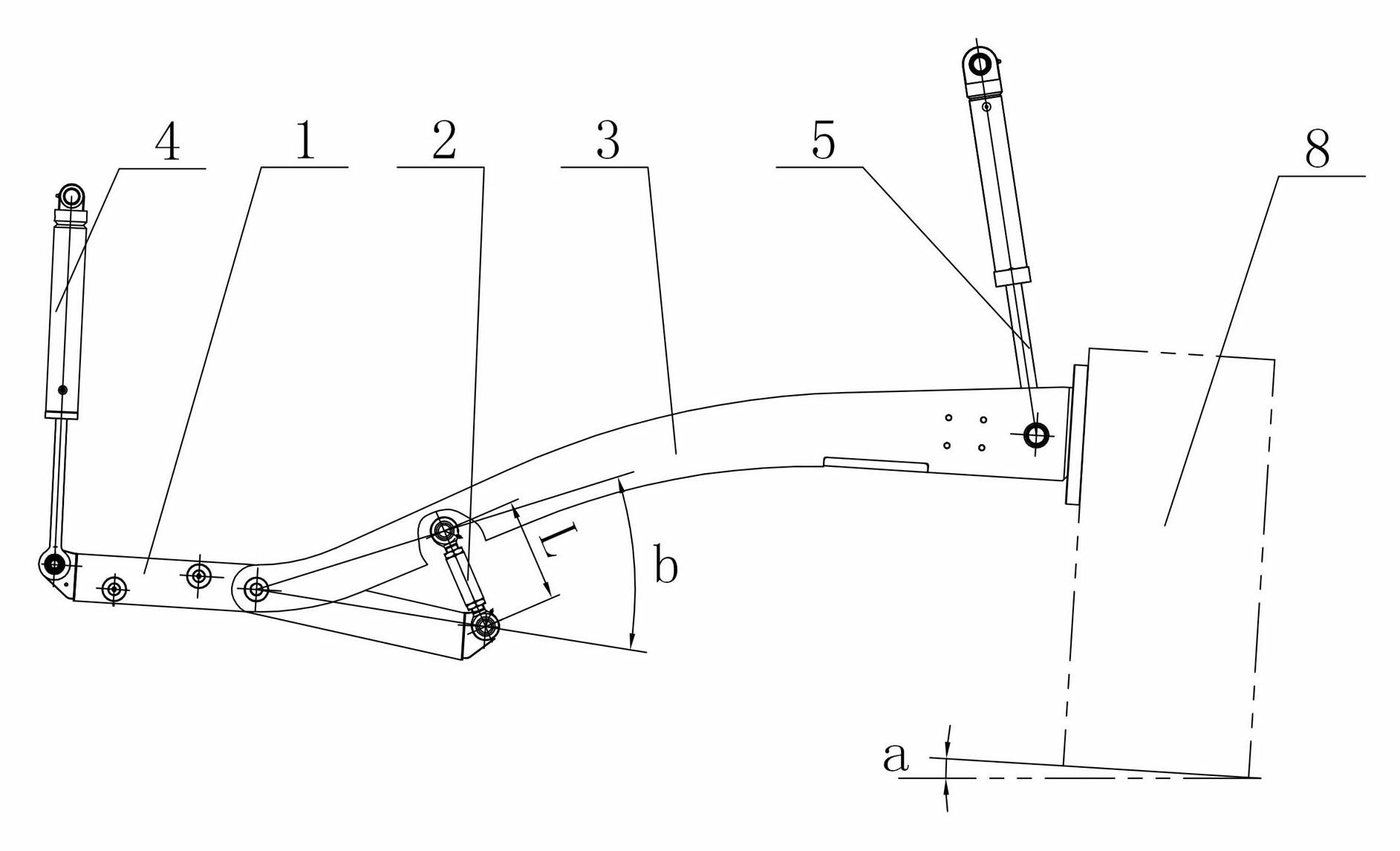

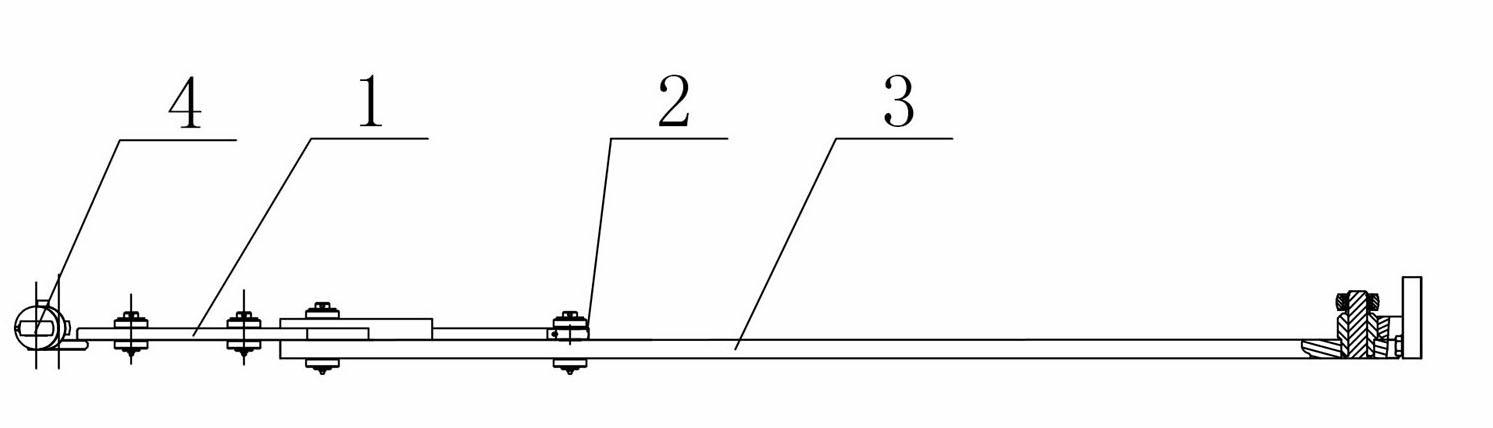

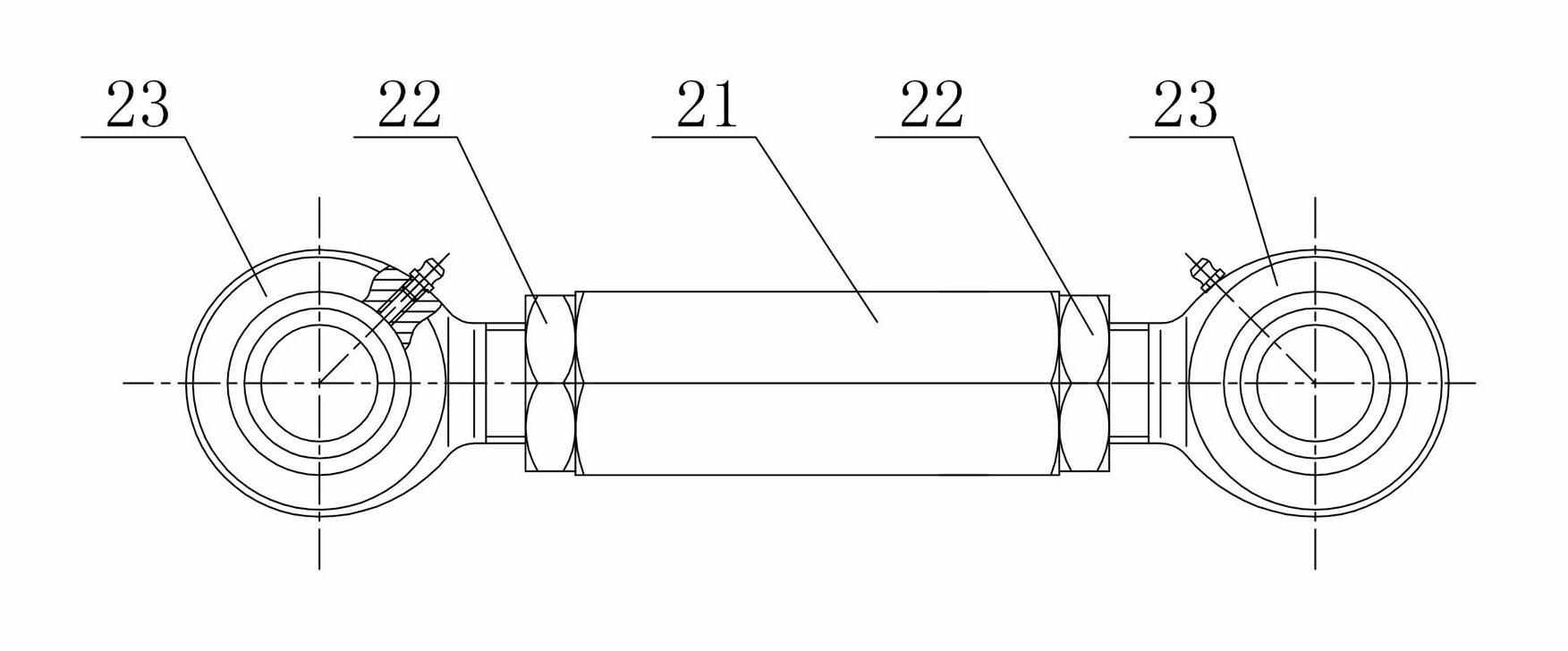

[0023] Figure 1 to Figure 3 It shows an embodiment of an angle-adjustable paver traction arm of the present invention, which comprises a front traction arm 1, a boom 3 and a leveling cylinder 4, and the leveling cylinder 4 is installed at the front end of the front traction arm 1. The rear end of the arm 3 is equipped with a boom lifting oil cylinder 5, and the front end of the boom 3 is hinged to the middle part of the front traction arm 1, and an adjusting device 2 that can adjust the angle between the front traction arm 1 and the boom 3 is provided. The device 2 adjusts the angle between the front traction arm 1 and the main arm 3 to realize the adjustment of the elevation angle of the paver screed. This structure does not need the rear main arm of the existing paver traction arm, which simplifies the traction The structure and installation steps of the arm reduce mechanical failure points and make the operation of the equipment more stable and reliable.

[0024] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com