Goods discharging module of automatic vending machine

A vending machine and delivery port technology, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. , poor contact and other problems, to achieve the effect of reducing mechanical failure points, convenient installation, and simplifying installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

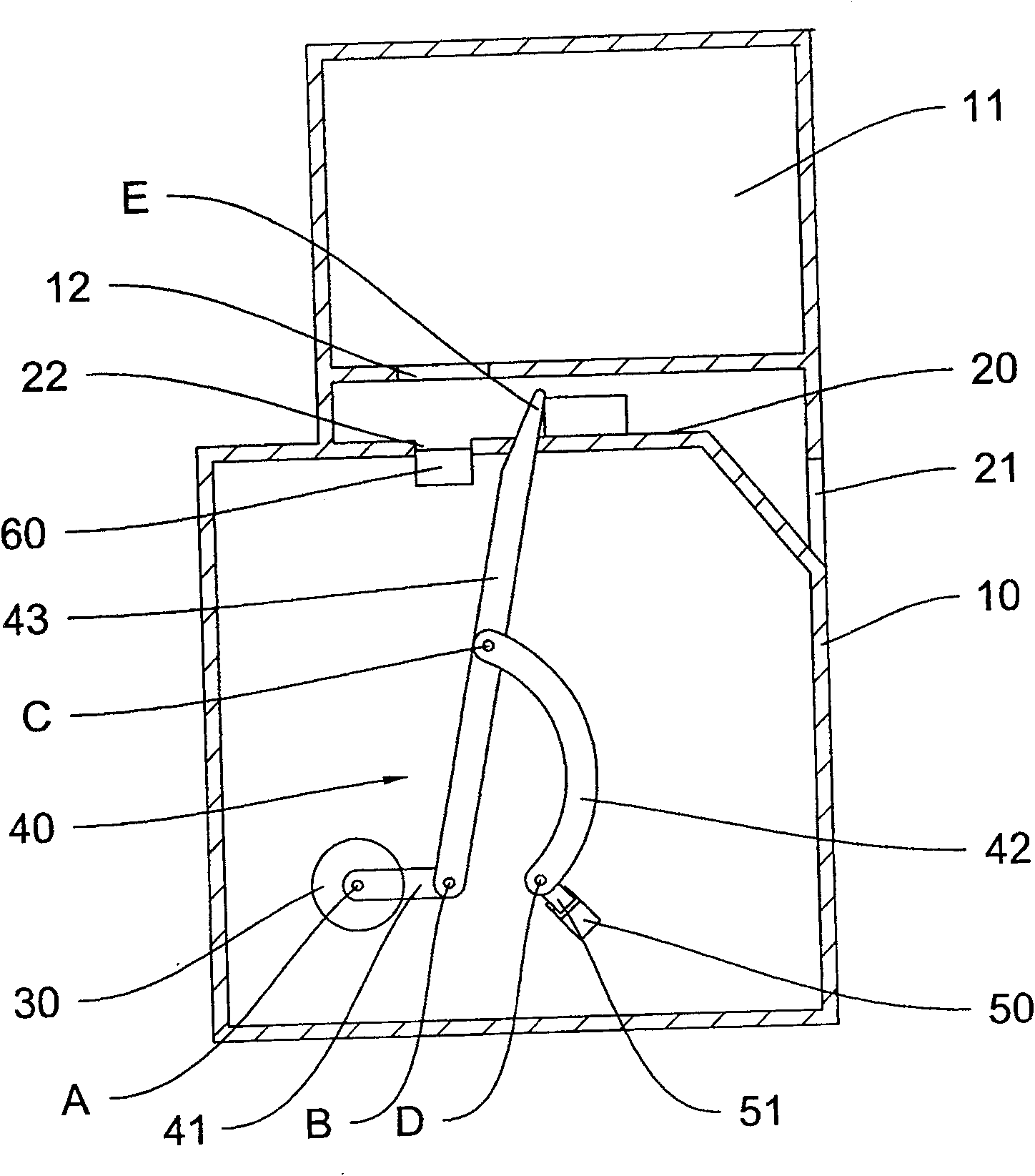

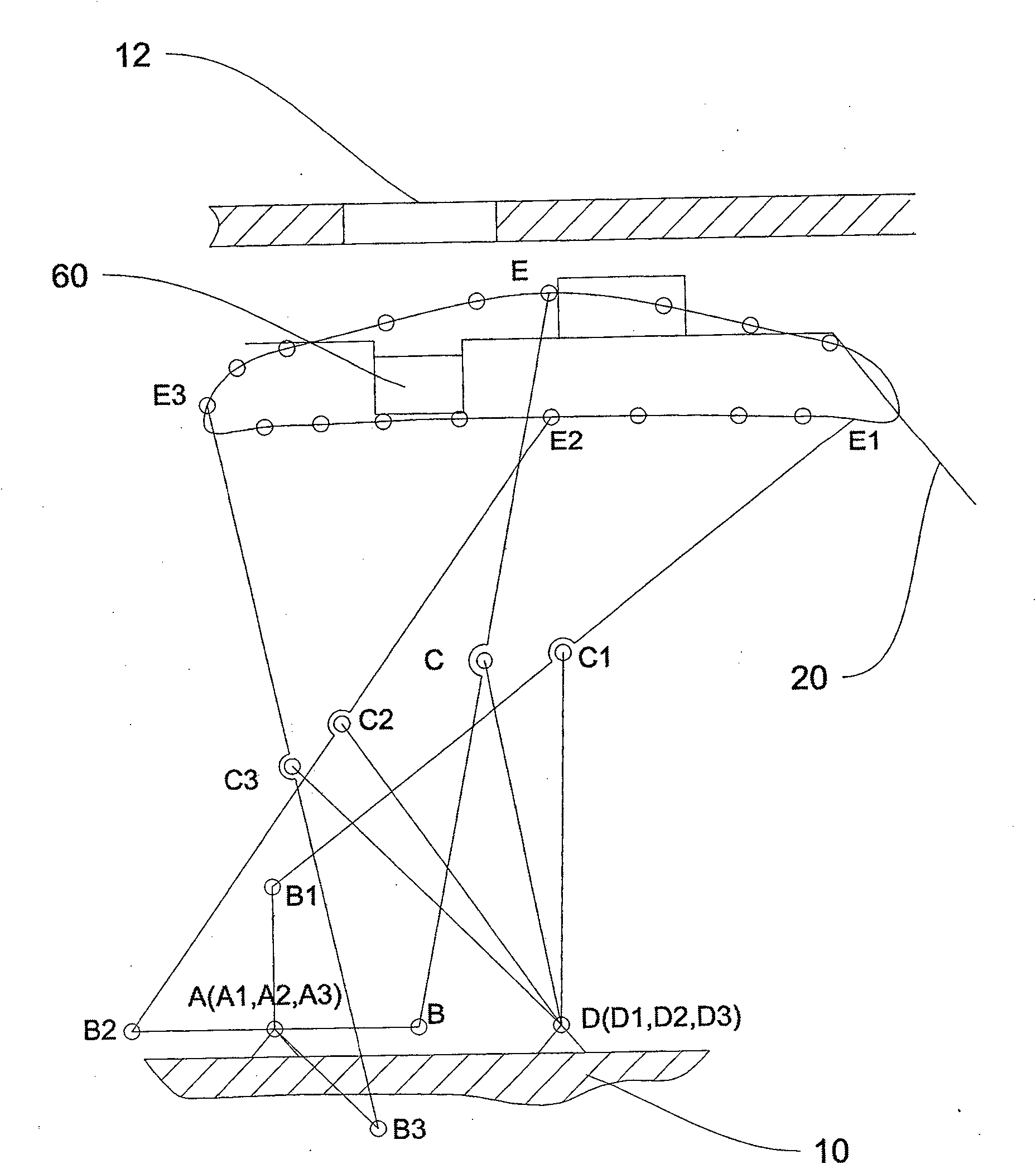

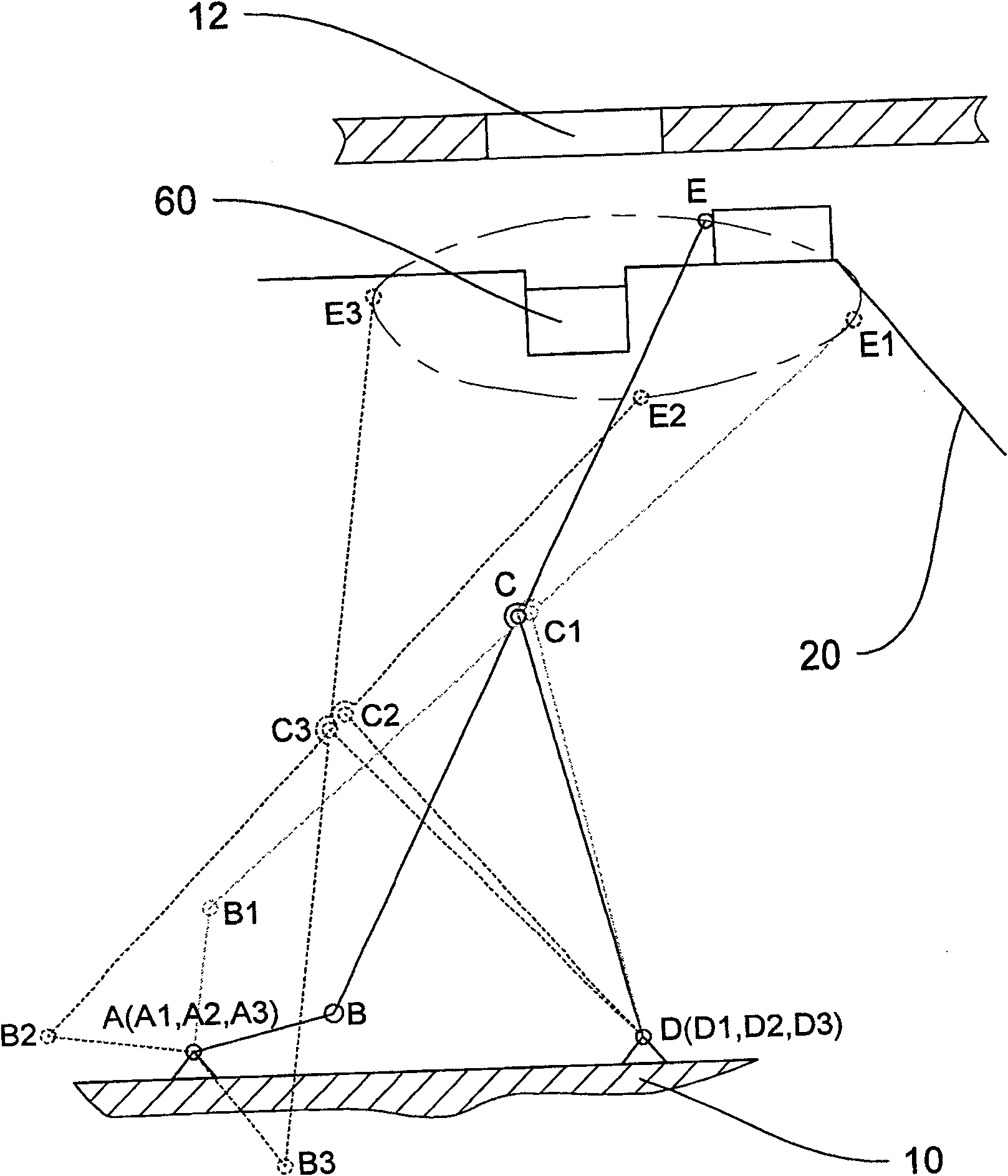

[0015] like figure 1 As shown, in the first embodiment of the delivery module of the automatic vending machine of the present invention, it includes the body 10, the cargo lane 20 arranged on the upper part of the body 10, the picking mechanism 40 arranged in the body 10, and the goods fixed on the side of the body 10. The motor 30 on the side. The side of the machine body 10 facing the user is the front side, and the cargo lane 20 is longitudinally arranged below the storage box 11 on the upper part of the machine body 10; at the bottom of the storage box 11, that is, a cargo inlet is provided above the middle of the cargo lane 20. 12. The goods in the storage box 11 fall into the goods lane 20 from the goods inlet 12. The front end of the cargo lane 20 is an outlet 21 provided on the front side of the body, and the cargo lane 20 is inclined downward near the outlet 21 to facilitate the sliding of goods.

[0016] The goods picking mechanism is a four-bar mechanism 40 , whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com