Solid-solid heat exchange device starting protection device, using method thereof and heat exchange device

A technology of protection device and heat exchange device, which is applied in the field of heat exchange equipment to achieve the effects of cost reduction, reduction of mechanical failure points, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

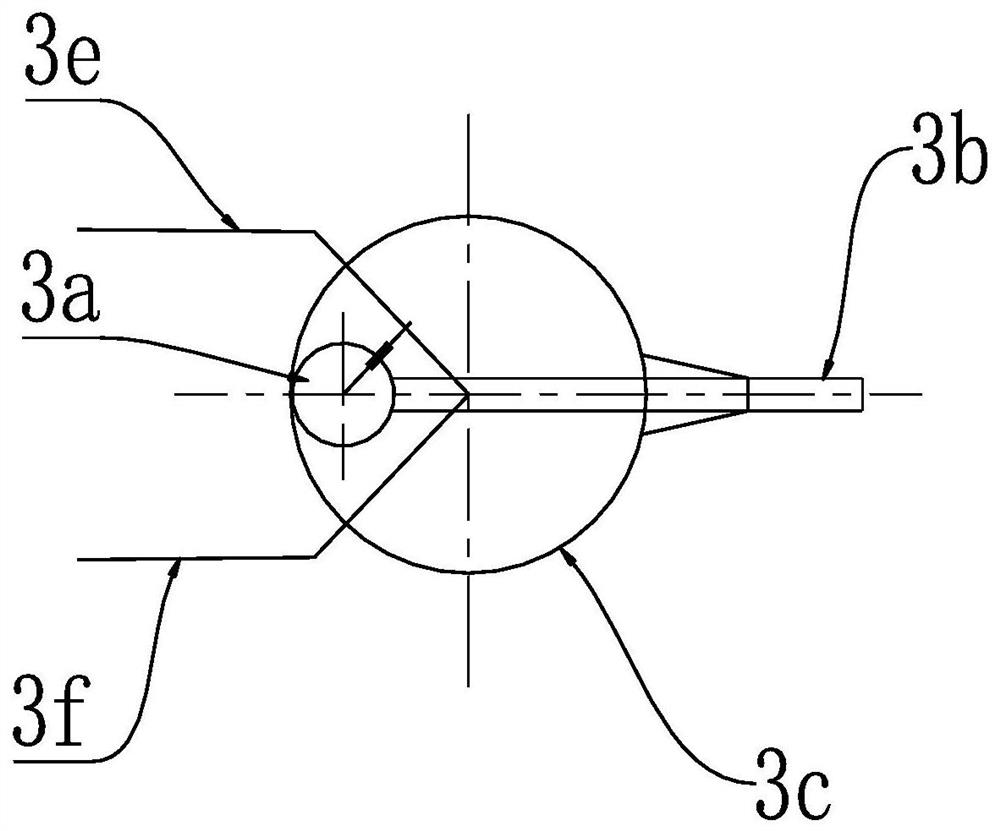

[0042] Example 1 - Solid-solid heat exchange device startup protection device

[0043] Such as figure 2 As shown, the solid-solid heat exchange device starts the protection device, including the protection device heating pipe 3a, superheated steam introduction pipe 3b, mixing header 3c, evaporating heating surface tube outlet 3e and evaporating heating surface tube inlet 3f;

[0044] The protection device heating pipe 3a is arranged in the mixing header 3c, and one end of the protection device heating pipe 3a is connected to the superheated steam introduction pipe 3b outside the mixing header 3c, and several small holes for discharging steam are uniformly and densely distributed on the protection device heating pipe 3a.

[0045] It can be understood that, as a reasonable expansion, the small holes do not have to be arranged uniformly and / or densely, and the uniformly densely arranged small holes are for heating the water in the mixing header 3c as efficiently as possible and ...

Embodiment 2

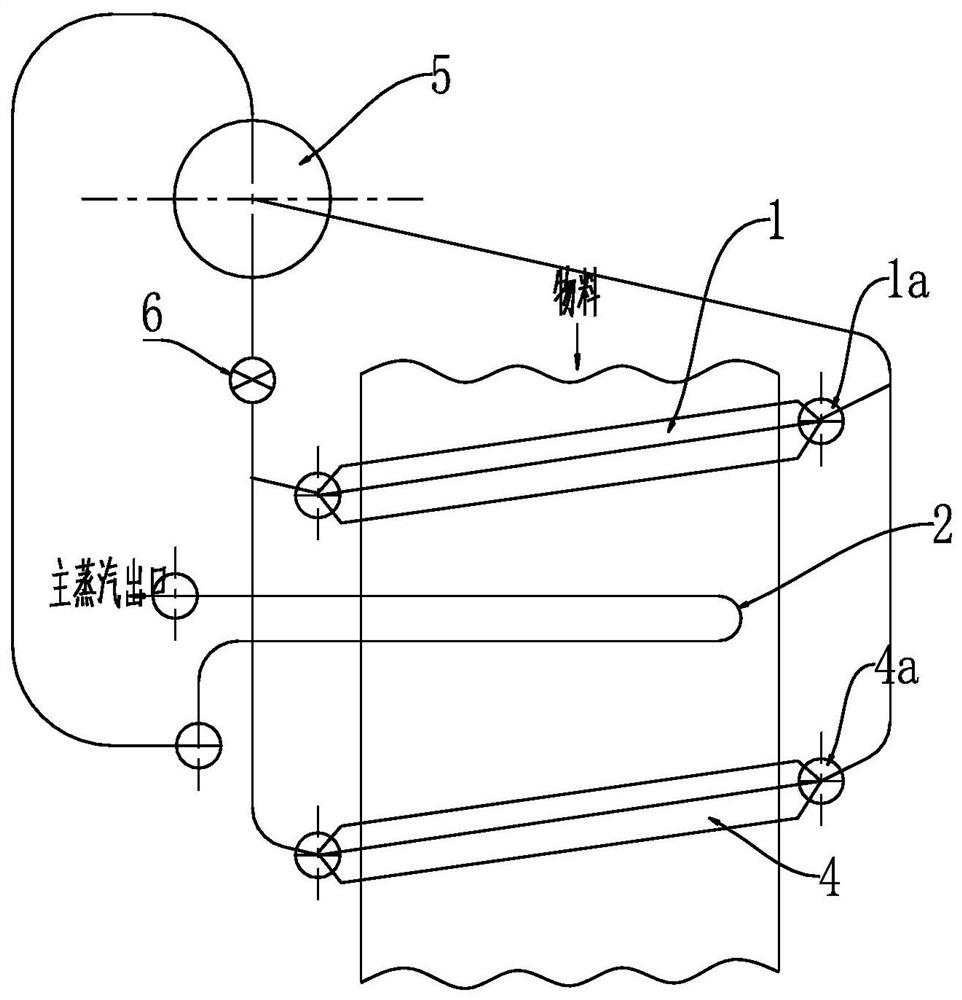

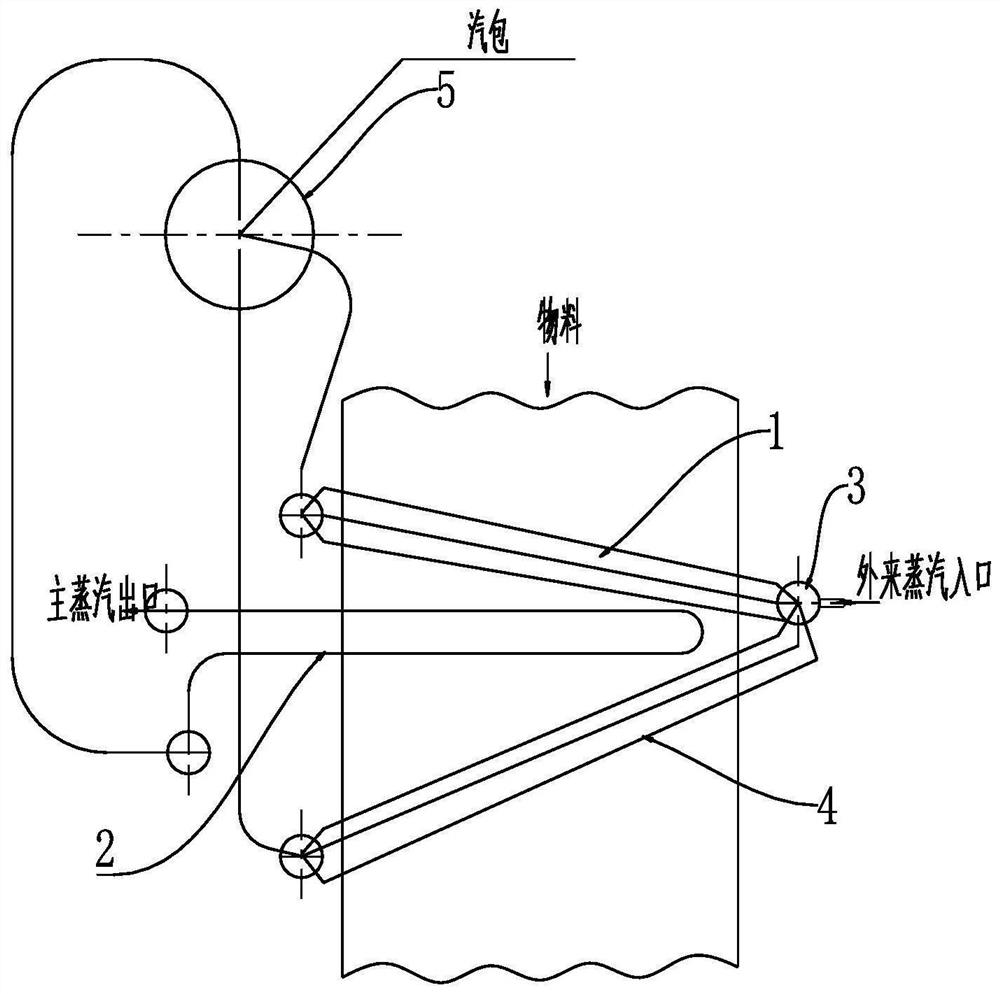

[0055] Embodiment 2 - heat exchange device

[0056] The present invention also provides a heat exchange device, including a primary evaporator 1 and a secondary evaporator 4, and adopts the solid-solid heat exchange device startup protection device as described in Example 1, the primary evaporator 1 The inlet is connected to the outlet 3e of the evaporation heating surface tube of the solid-solid heat exchange device startup protection device, and the outlet of the secondary evaporator 4 is connected to the evaporation heating surface tube inlet 3f of the solid-solid heat exchange device startup protection device.

[0057] Such as image 3 As shown, an example of a heat exchange device applying a solid-solid heat exchange device to start a protection device is described in detail.

[0058] In this example, the mixing header 3c of the starting protection device of the solid-solid heat exchange device replaces the primary evaporator outlet header 1b of the primary evaporator 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com