Method and device for double-sided opposite printing for engraved intaglio plate

A technology of engraving gravure and printing methods, which is applied to gravure rotary printing machines, printing, printing of special varieties of printed matter, etc. It can solve the problems of short pressure release rebound time, high frequency of pressure, and poor product quality, etc., to achieve Long reset time, the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

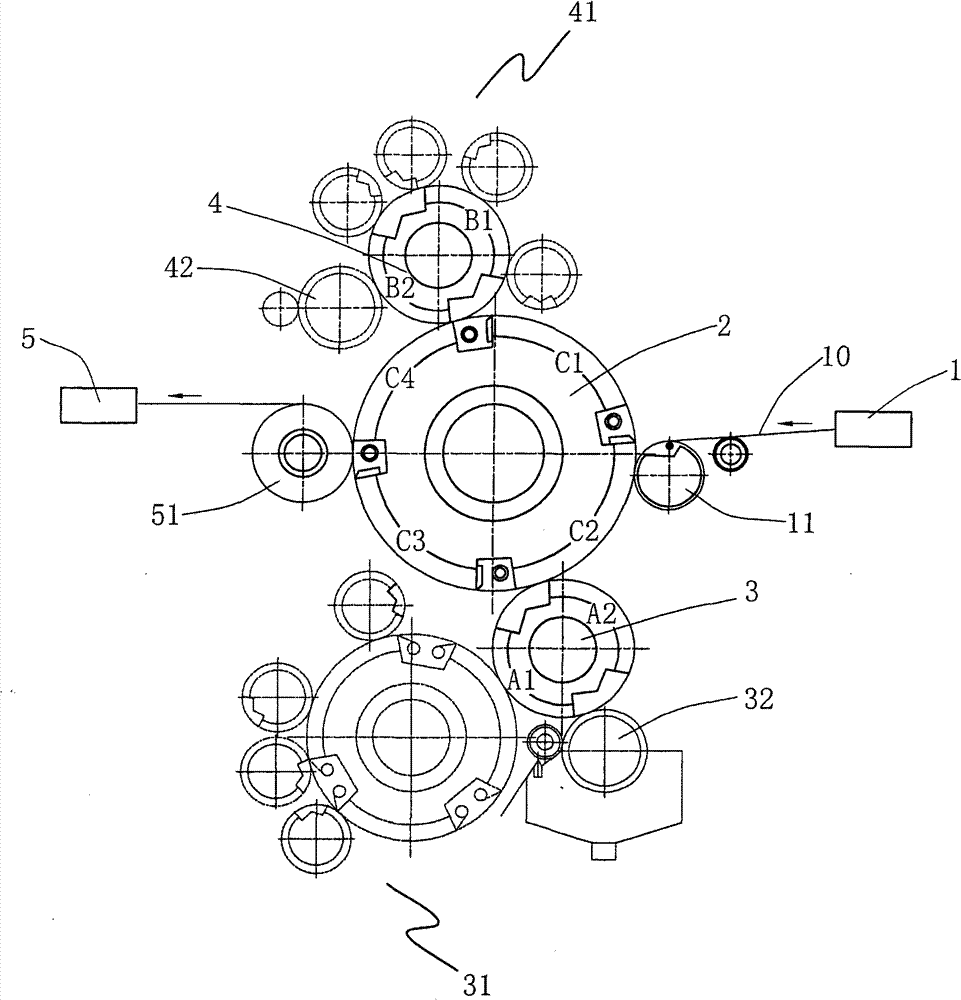

[0028] figure 1 It is a schematic diagram of the printing principle of the present invention. As shown in the figure, the engraved gravure double-face printing device of the present invention includes: a substrate control part, which has a substrate input part 1 and an output part 5 respectively arranged at the front and rear ends of the transfer / impression cylinder 2, and In this embodiment, the substrate is paper 10, and the paper 10 is transported to the transfer / impression cylinder 2 by the paper feed cylinder 11 of the substrate input part 1, and passes through the paper output cylinder of the substrate output part 5 after printing is completed. 51 were collected. Two printing plate cylinders 3, 4 (the first and second printing plate cylinders 3, 4), each printing plate cylinder 3, 4 is equipped with an even number of printing plates with equal numbers respectively, and the front and back of the substrate The two-sided printing plates are arranged on two plate cylinders...

Embodiment approach 2

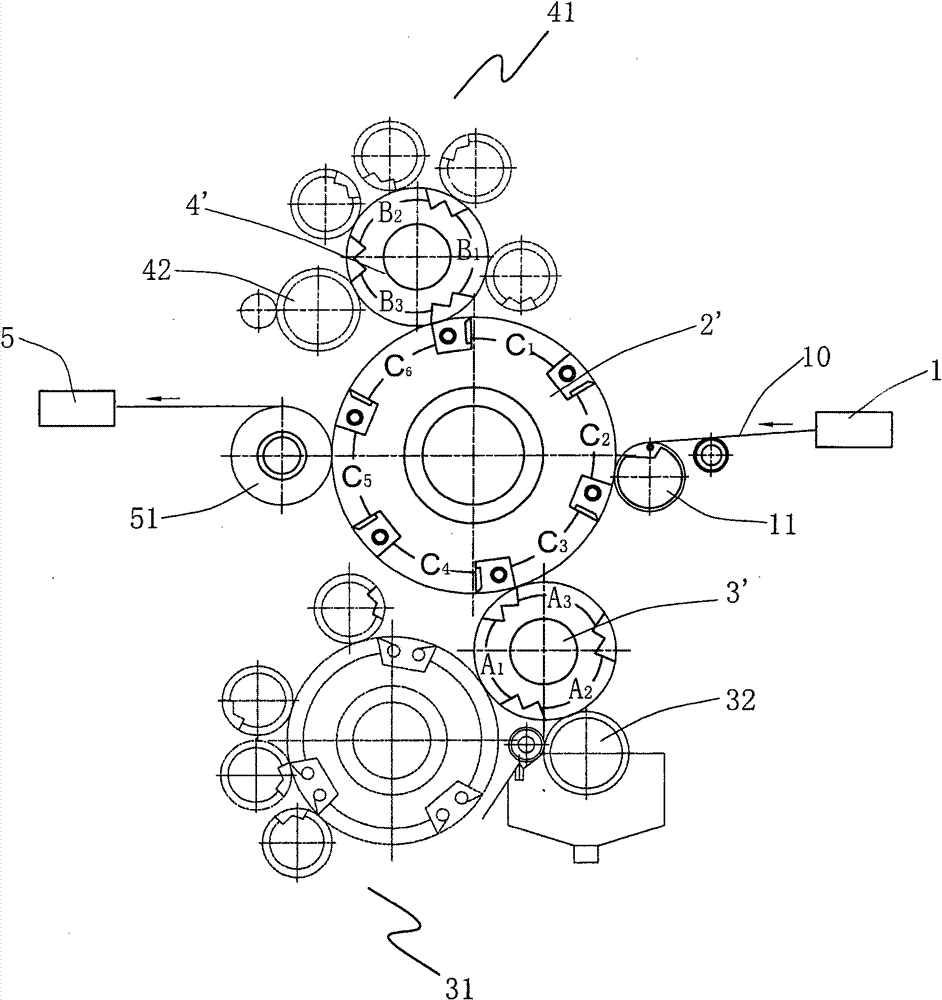

[0041] figure 2 It is a schematic diagram of the printing principle of another embodiment of the present invention, wherein the same components as in the embodiment use the same symbols. As shown in the figure, three first printing plates A can be set on the first printing plate cylinder 3' 1 、A 2 、A 3 , three second printing plates B are also set on the second printing plate cylinder 4' 1 , B 2 , B 3 , In this embodiment, the front printing plate is set on the first printing plate cylinder 3', and the back printing plate is set on the second printing plate cylinder 4' as an example for description. The transfer / imprint cylinder 2' is equipped with an even-numbered transfer / imprint cushion layer twice as many as the number of printing plates provided on the first and second plate cylinders 3', 4', namely Set with six transfer / imprint pads C 1 、C 2 、C 3 、C 4 、C 5 、C 6 The diameter ratio of the first and second plate cylinders 3', 4' to the transfer / impression cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com