Automatic paper feeding device

An automatic paper feeding device and paper technology, applied in the direction of transportation and packaging, separation of objects, electrical components, etc., can solve problems such as noise, shortening the service life of the paper fetching arm, and increasing the force of the paper fetching arm hitting the paper inlet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

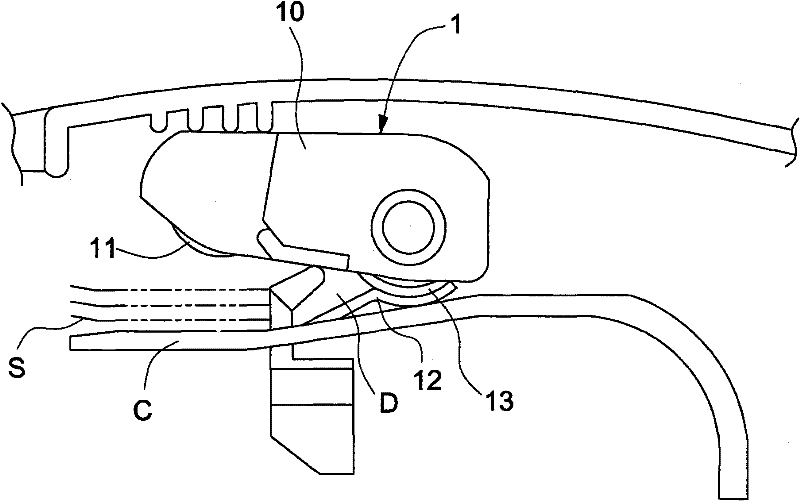

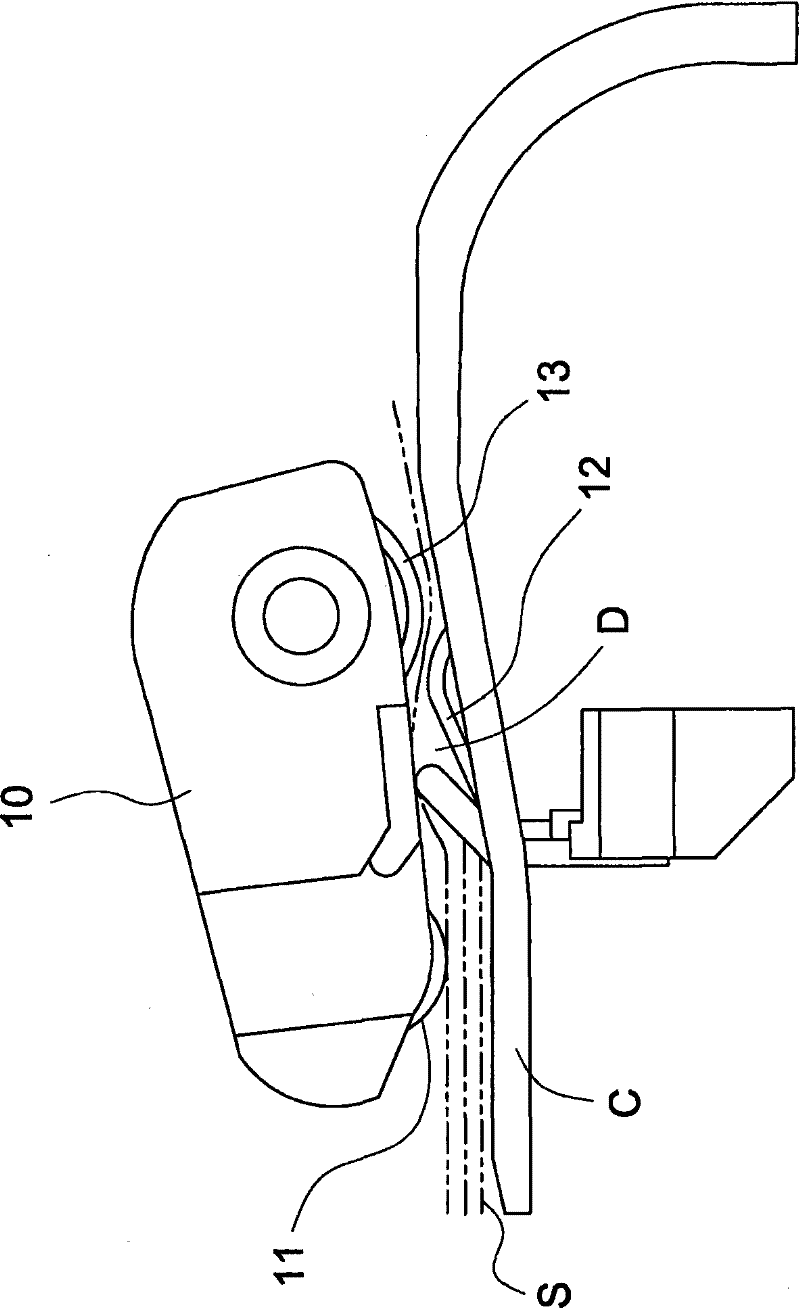

[0035] According to a specific embodiment of the present invention, an automatic paper feeding device is provided, which can be applied to a multifunctional business machine or an automatic paper feeding scanner.

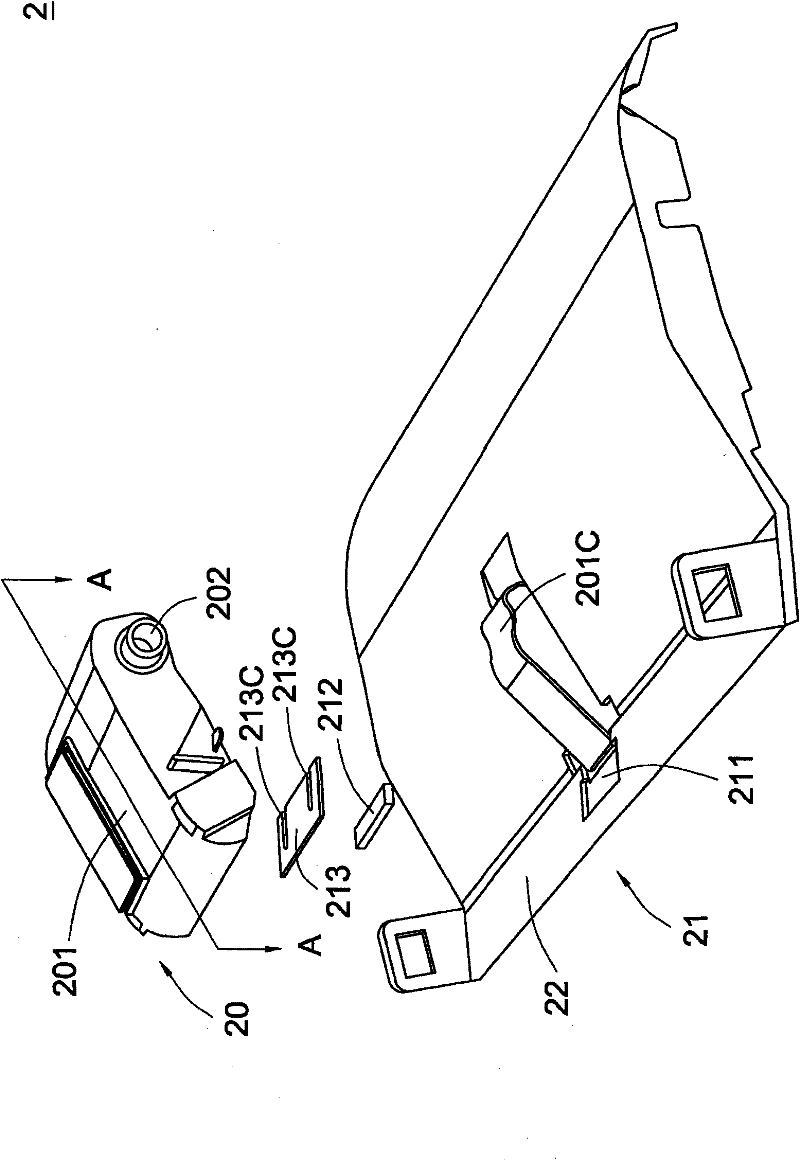

[0036] image 3 It is an exploded view showing an automatic paper feeding device according to a preferred embodiment of the present invention. The automatic paper feeding device 2 includes a paper picking module 20 and a floating shock-absorbing structure 21 . The paper-feeding module 20 is used to feed paper into the interior of the automatic paper feeding device 2, including a paper-feeding arm 201 and a rotating shaft 202, while the floating shock-absorbing structure 21 includes a groove 211 at the paper inlet 22, a foam 212 And a friction plate 213.

[0037] Continue to refer to image 3 , the foam 212 is set in the groove 211 (please also refer to Figure 4A ), and the foam 212 does not fill the groove 211, and the friction plate 213 covers the groove 211 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com