Electrowetting-type display device, drive method and manufacturing method thereof

A technology of a display device and a manufacturing method, which can be applied to static indicators, optics, instruments, etc., can solve the problems of inability to emit light and power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

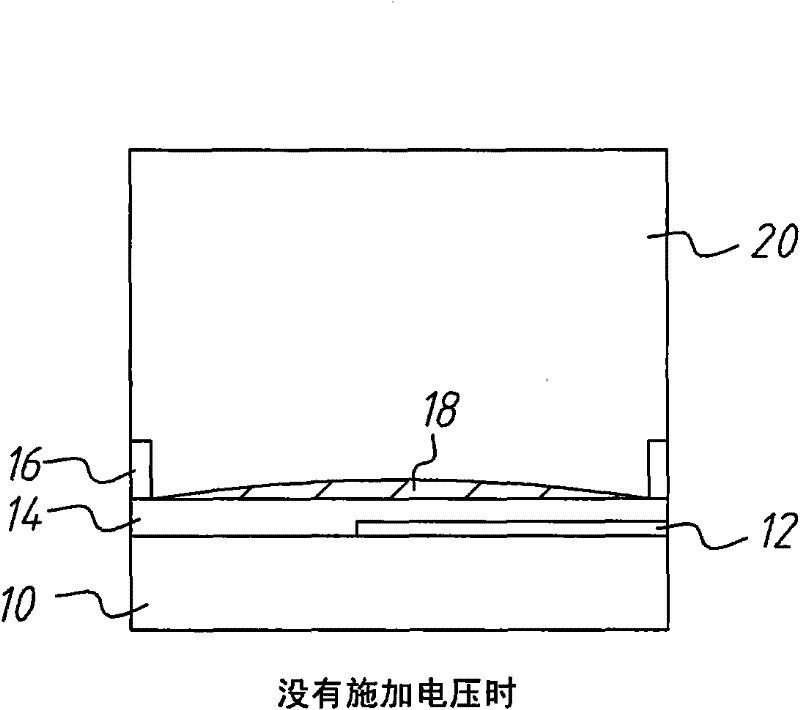

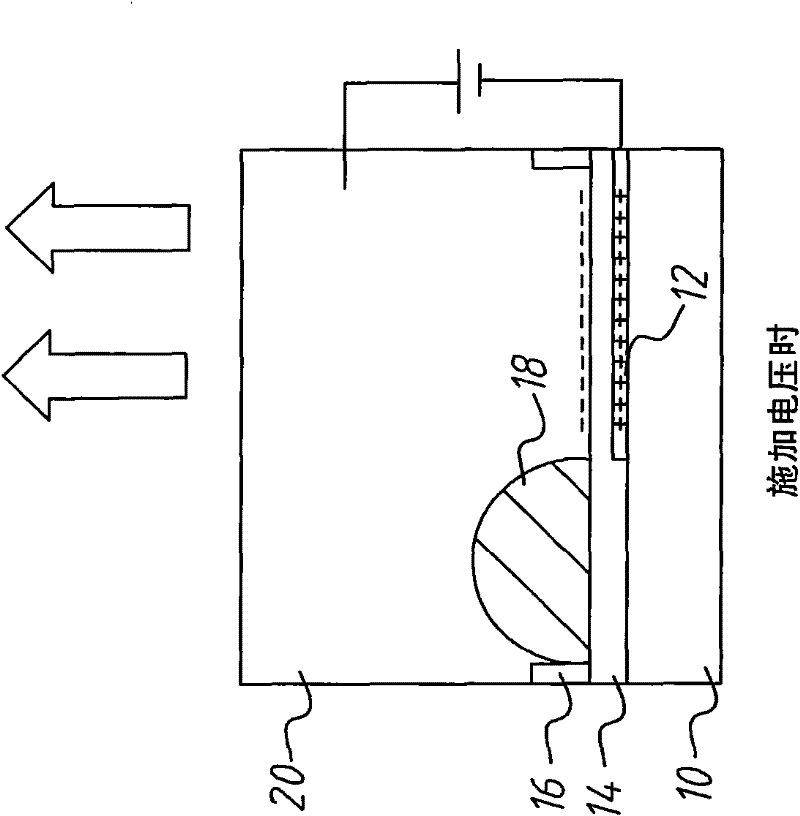

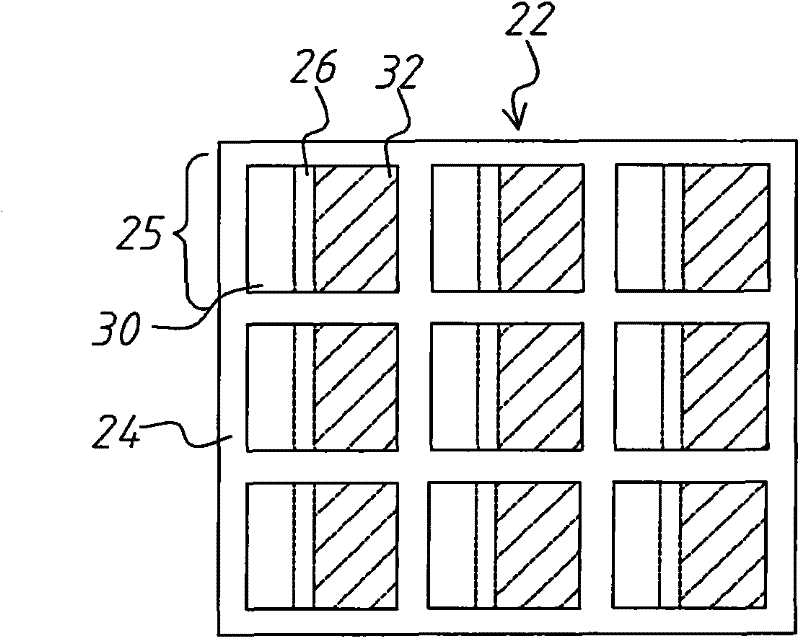

[0020] The first embodiment of the structure of the electrowetting display device proposed by the present invention is as follows figure 2 , image 3 As shown, the device includes a thin film transistor substrate 22 as a first substrate, a hydrophilic barrier structure 24 as a barrier structure, and a plurality of display units 25. The hydrophilic barrier structure 24 is located on the thin film transistor substrate 22, so as to The thin film transistor substrate 22 is divided into multiple areas, and each display unit 25 is respectively arranged on each area. Since the structures included in each display unit 25 are the same, therefore image 3 Only the structural cross-sectional view of the display unit 25 and the surrounding hydrophilic barrier structure 24 and the TFT substrate 22 is shown.

[0021] The display unit 25 includes at least one hydrophilic isolation structure 26, at least two electrode blocks 28, at least two hydrophobic insulating blocks 30, a colored liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com