Recoil-free ejecting device

A technology of recoil and rear piston, which is applied in the direction of weapon accessories, missile propellers, offensive equipment, etc. It can solve the problems of small mass, launch tube and bullet without electrical interface, etc., and achieve the effect of eliminating recoil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

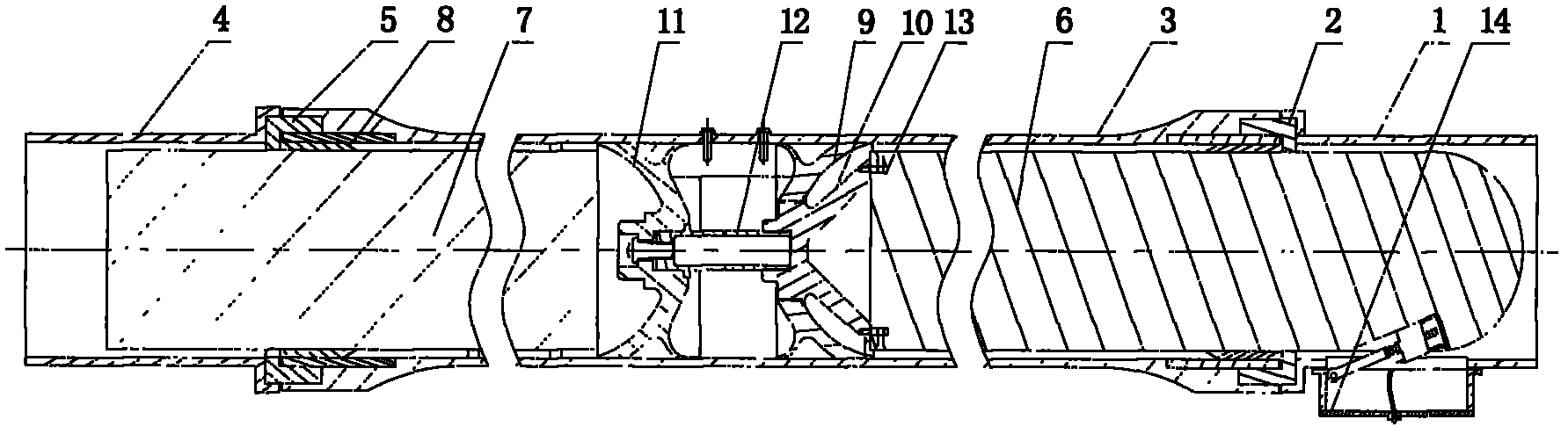

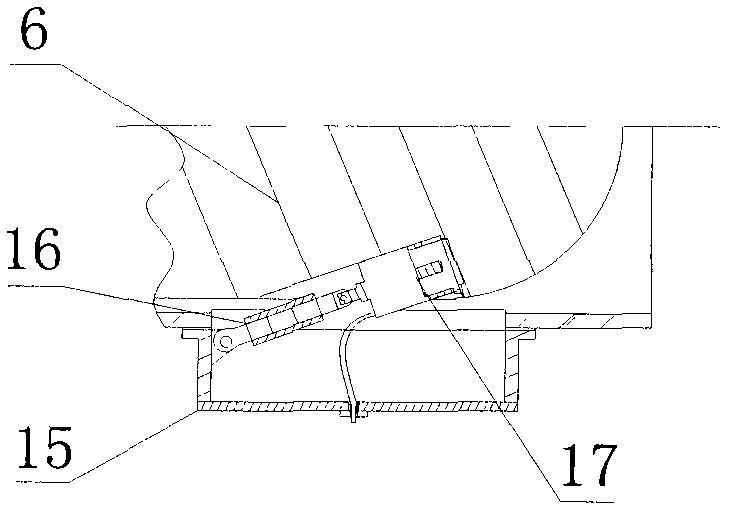

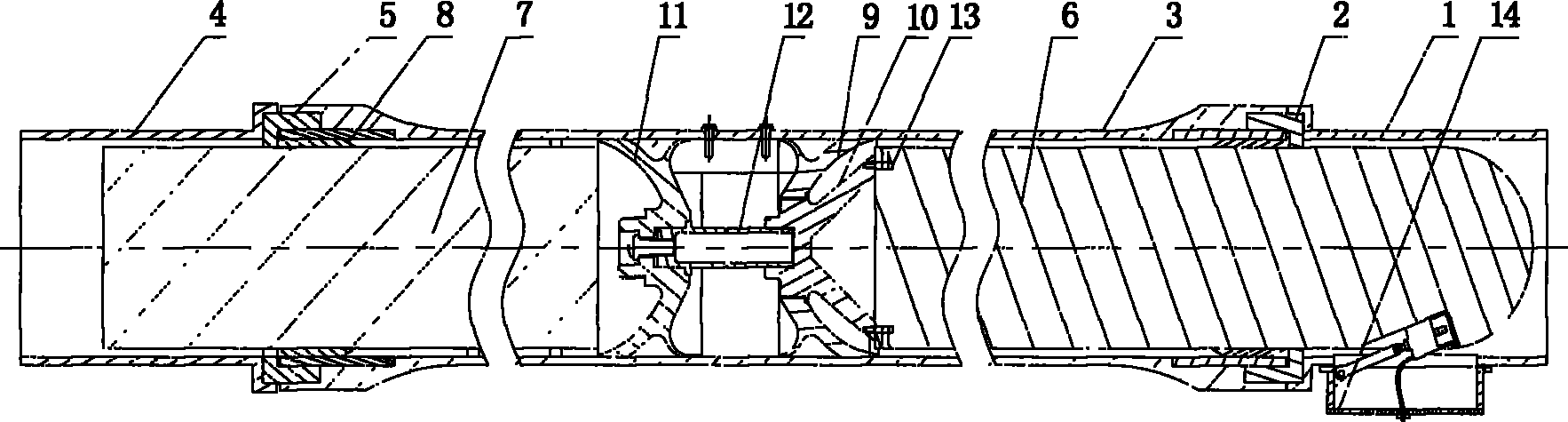

[0010] A recoilless projectile device, comprising: front cylinder body 1, front flange 2, middle cylinder body 3, rear cylinder body 4, rear flange 5, balance body 7, brake ring 8, front piston body 9, support seat 10. The rear piston 11, the ignition tube 12 and the lug 13 also include: a plug-in mechanism 14. Wherein, the plug-in mechanism 14 includes: a housing 15, an adjustable pull rod 16 and an electrical plug 17. One end of the support seat 10 is threadedly connected with the front piston body 9, and the other end is in the shape of a bell mouth. 13, one end is placed in the threaded hole, and the other end is screwed with the bullet 6. The rear piston 11 is threadedly connected with the balance body 7, the two ends of the middle cylinder 3 are threaded, the brake ring 8 is clamped with the two ends of the middle cylinder 3, the front flange 2 and the rear flange 5 are connected with the middle cylinder 3 Screwed and connected with brake ring 8 at the same time. One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com