Explosive substance destroy machine and special warhead thereof

A technology for explosives and warheads, which is applied in the direction of warheads, ammunition, projectiles, etc., which can solve the problems of power discount, recoil reduction, safety hazards, etc., and achieve the effect of low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 explosive destroyer

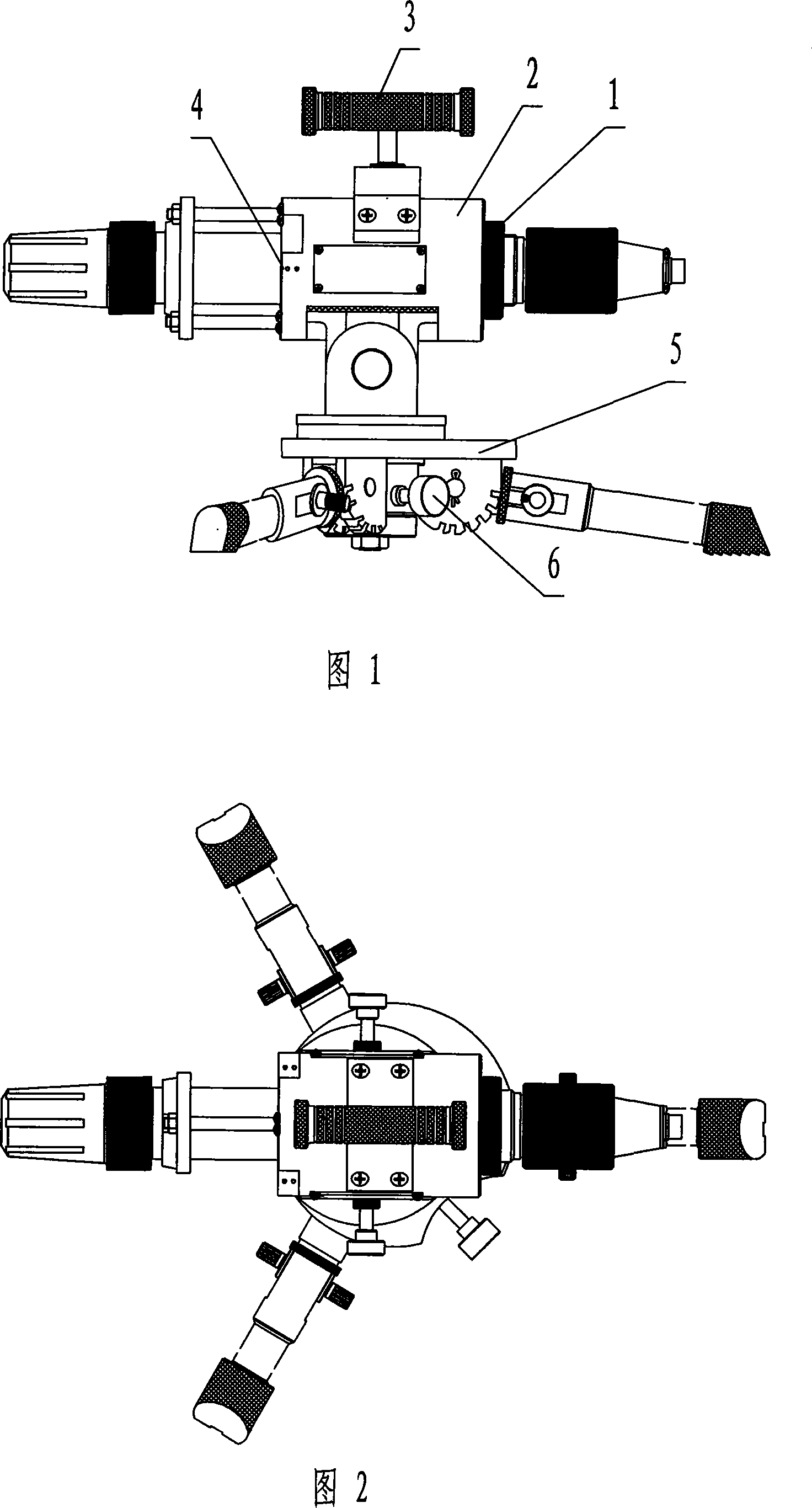

[0061] The main components of the explosive destroyer of the present invention constitute as figure 1 shown. It consists of a launcher 1, a buffer seat 2 socketed outside the launcher 1, a handle 3 installed on the upper part of the buffer seat 2, a two-way laser sight 4 installed on the side of the buffer seat 2, and connected to the lower part of the buffer seat 2. The tripod type supporting device 5 and the locking hand wheel 6 are composed.

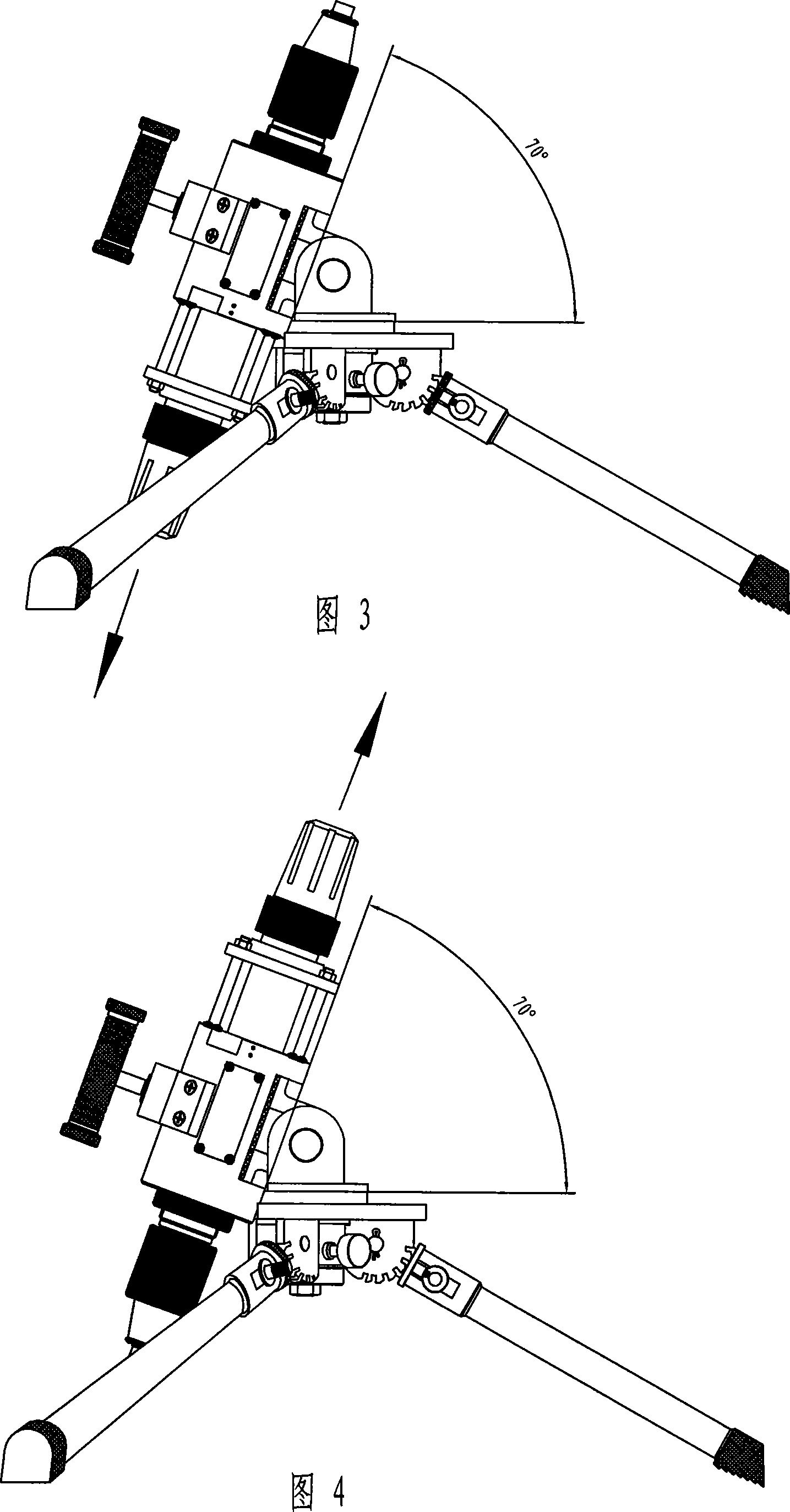

[0062] By adjusting the locking handwheel 6, the launching device 1 can be rotated arbitrarily at 360° in the horizontal direction and 70° in the up and down directions on the supporting device 5 without jamming. When positioning, it is locked by the locking handwheel 6, such as figure 2 , 3 , 4 shown.

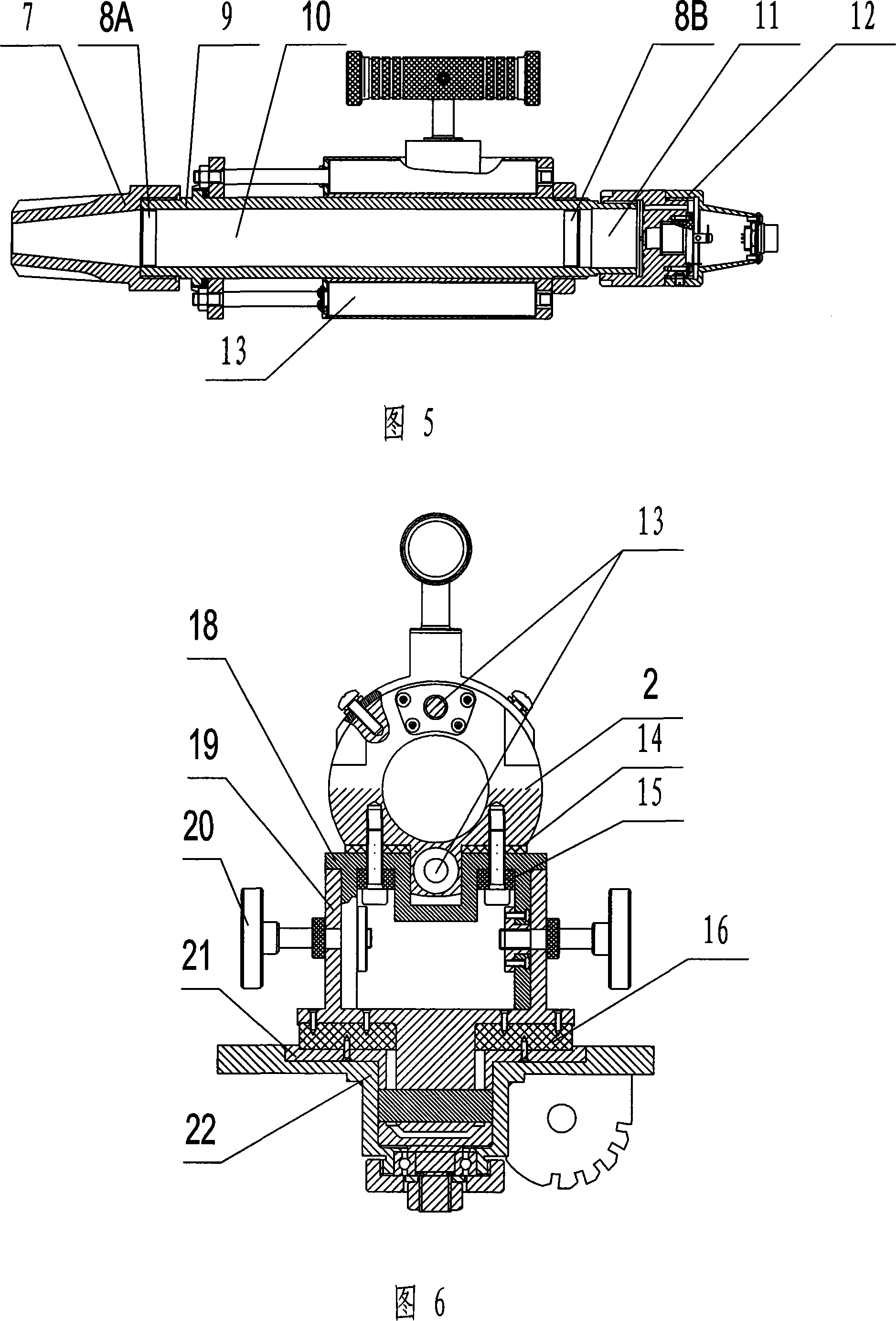

[0063] Figure 5 is a detailed structural diagram of the launcher. Whole launching device 1 is made up of launch tube 9, taper-shaped faucet 7 installed on the front end of launch tu...

Embodiment 2

[0072] Embodiment 2 Explosive Destroyer Dedicated Submunition

[0073] 38mm conical submunitions such as Figure 14 shown. Wherein, the tapered bullet tip 41 made of steel is fastened on the plexiglass cone 42 to form a sub-body, and the cone 42 rear has a hollow cylinder whose size is just enough to be inserted into the plexiglass matrix 43 . The shape of the mother body 43 is hollow in the front cone and the back circle, and an elastic sealing ring 44 is arranged on the cylinder at the rear part of the mother body 43 .

[0074] Take off water nozzle 7 during application, replace front end water plug 8A with this conical submunition and be installed in launch tube 9 front ends, fill into water in launch tube 9. By triggering the explosive destroyer, the submunition can penetrate steel plates or thicker wooden boards up to 2mm thick, and can also destroy the packaging of explosives that are difficult for water bombs to penetrate and disintegrate. When the design of this s...

Embodiment 3

[0075] Embodiment 3 Special Bullet for Explosive Destroyer

[0076] steel bullets such as Figure 15 , 16 shown. The conical attack warhead 45 is processed by stainless steel, and its front end is a truncated cone, and the hollow part is processed into a cylindrical shape. Its rear portion is provided with the guide body 46 of three lobe plastic moldings, and its external diameter is consistent with launch tube 9 internal diameters.

[0077] During application, the conical attack warhead 45 and the guide body 46 are inserted into the launch tube 9 together. No water is poured into the launch tube 9, and when the explosive destroyer fires, the electric projectile 11 produces high-pressure gas to push the conical attack warhead 45 and the guide body 46 to shoot forward at high speed, and then the three-lobe guide body 46 falls off, and the conical attack Warhead 45 flies forward. Tests have proved that it can break through the packaging of hard explosives such as cast iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com