A recoilless cavitation cleaning nozzle

A technology for cleaning nozzles and cavitation, which is applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of reducing performance, tilting or collapsing the platform, and increasing the self-weight of the platform, so as to reduce assembly errors, eliminate recoil, and improve the structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

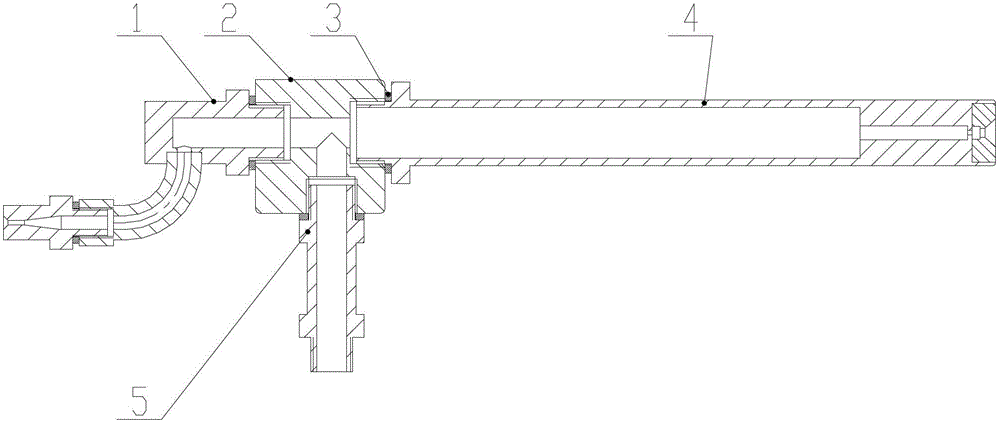

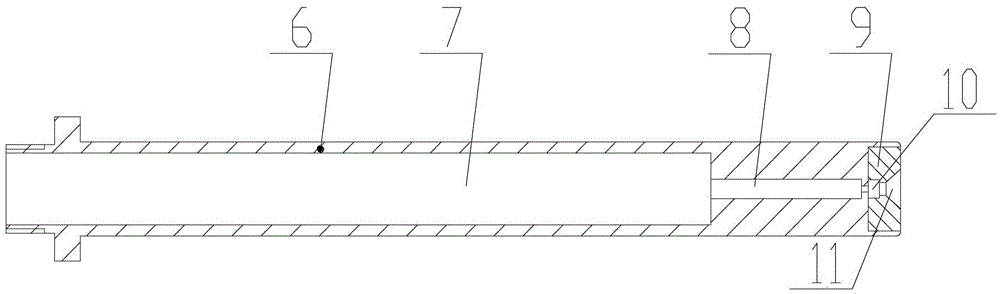

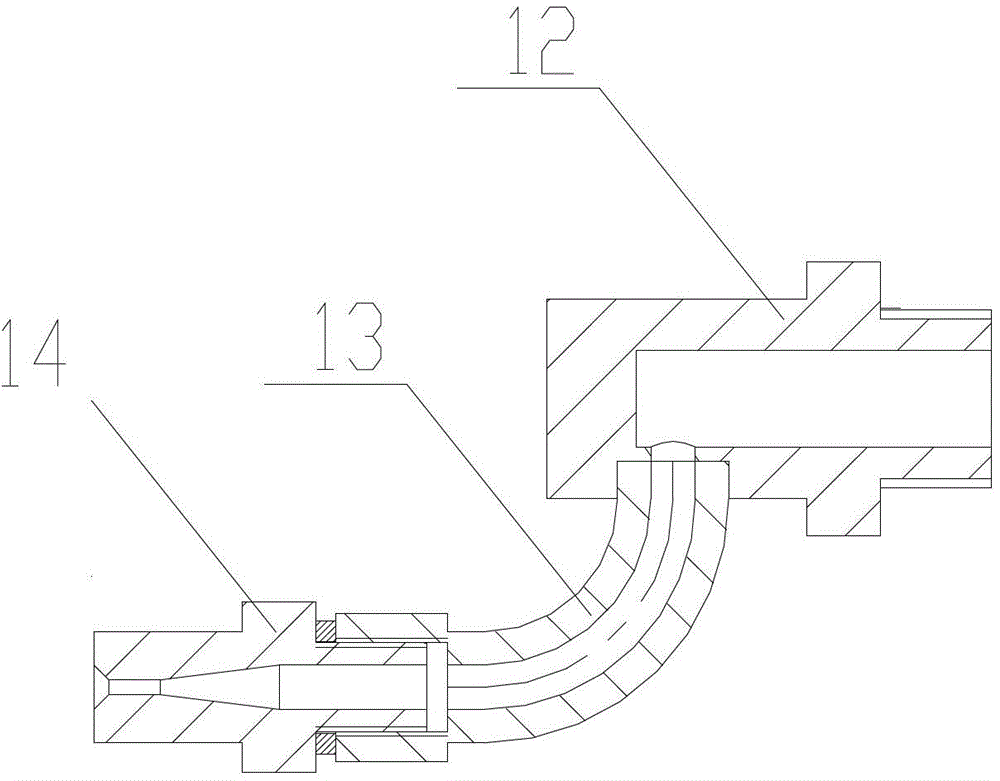

[0025] as attached figure 1 As shown, the present invention provides a recoilless cavitation cleaning nozzle, including a reverse injection mechanism 1, a valve seat 2, a combined sealing gasket 3, a cavitation injection mechanism 4 and a water inlet joint 5, and the reverse injection mechanism 1 , the cavitation injection mechanism 4 and the water inlet joint 5 are designed to have the same connection structure, but the nozzle sizes are different; in order to ensure reliable sealing and facilitate the replacement of various devices, the seal is selected from the standard combined gasket 3, and the connection interface of each device adopts Standard thread constructions of the same size; as attached figure 2 As shown, the cavitation injection mechanism 4 is composed of a pipe body 6 and a nozzle 9. The pipe body 6 has three stepped holes with continuousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com