Cutting machine for tyre

A cutting machine and tire technology, applied in metal processing and other directions, can solve the problems of non-parallel ends, affecting tire test pieces, and high production costs, and achieve the effects of low cutting cost, long service life, and low high-speed cutting wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

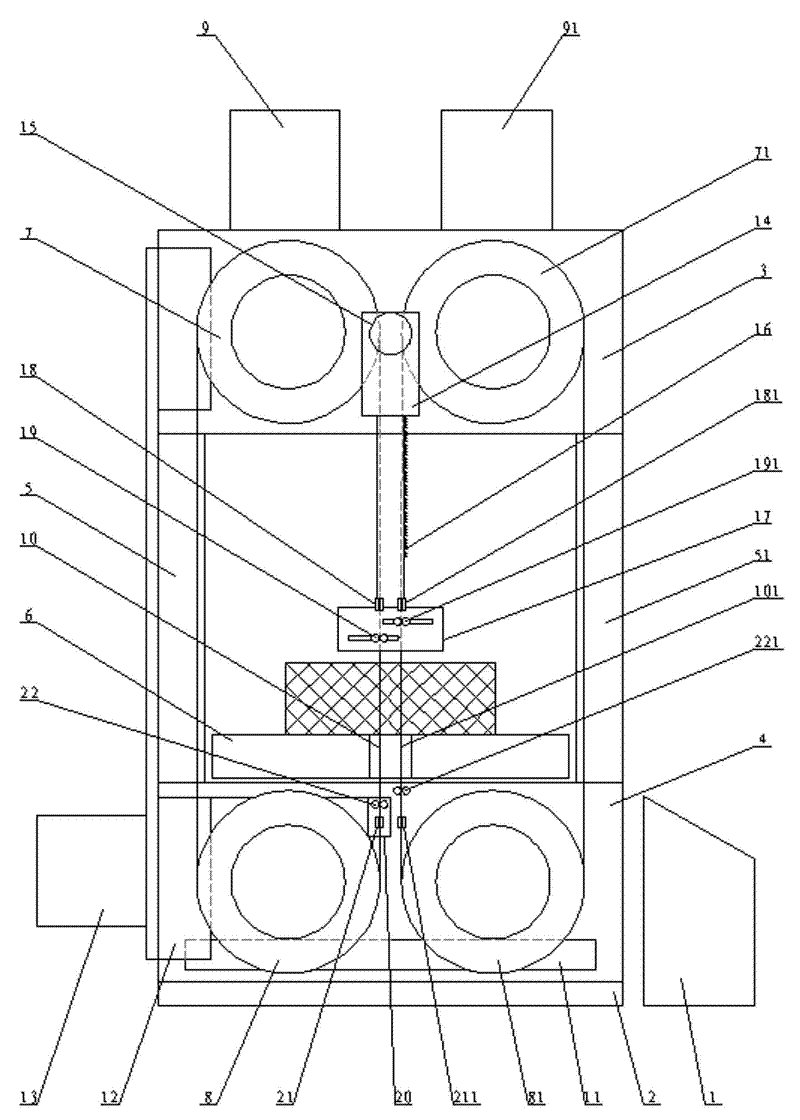

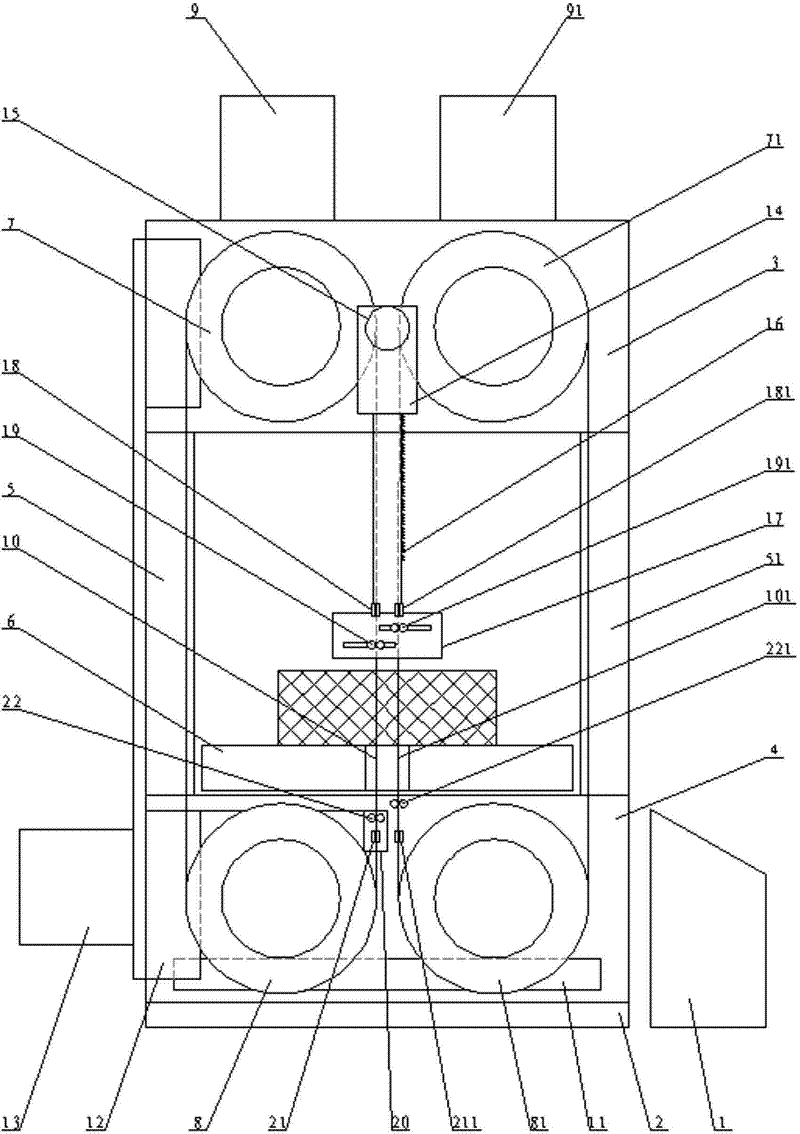

[0014] figure 1 As shown, the tire cutting machine mainly includes an electric control box 1, a machine base 2, an upper frame 3, a lower frame 4, a left protective frame 5, a right protective frame 51, a left driving wheel 7, a right driving wheel 71, and a left driven wheel 8, right driven wheel 81, left drive motor 9, right drive motor 91, left cutter belt 10, right cutter belt 101 and workbench 6. The base 2 is provided with a lower frame 4, the two sides of the lower frame 4 respectively support the upper frame 3 through the left and right protective frames 5, 51, and the workbench 6 is movably arranged on the lower part of the left and right protective frames 5, 51. The frame 4 is in a state of lifting and tilting. The workbench 6 is connected with a high-speed feed motor and a slow feed motor through a shift clutch. The shift clutch is connected with the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com