Testing method for laying ballastless tracks in early stage before overall completion of super long tunnel

A ballastless track and tunnel construction technology, applied in tunnels, mining equipment, measuring devices, etc., can solve problems such as ballastless track cannot be smoothly connected, rework, engineering correction, etc., to improve construction measurement accuracy, ensure smoothness and same time linear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] specific implementation plan

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

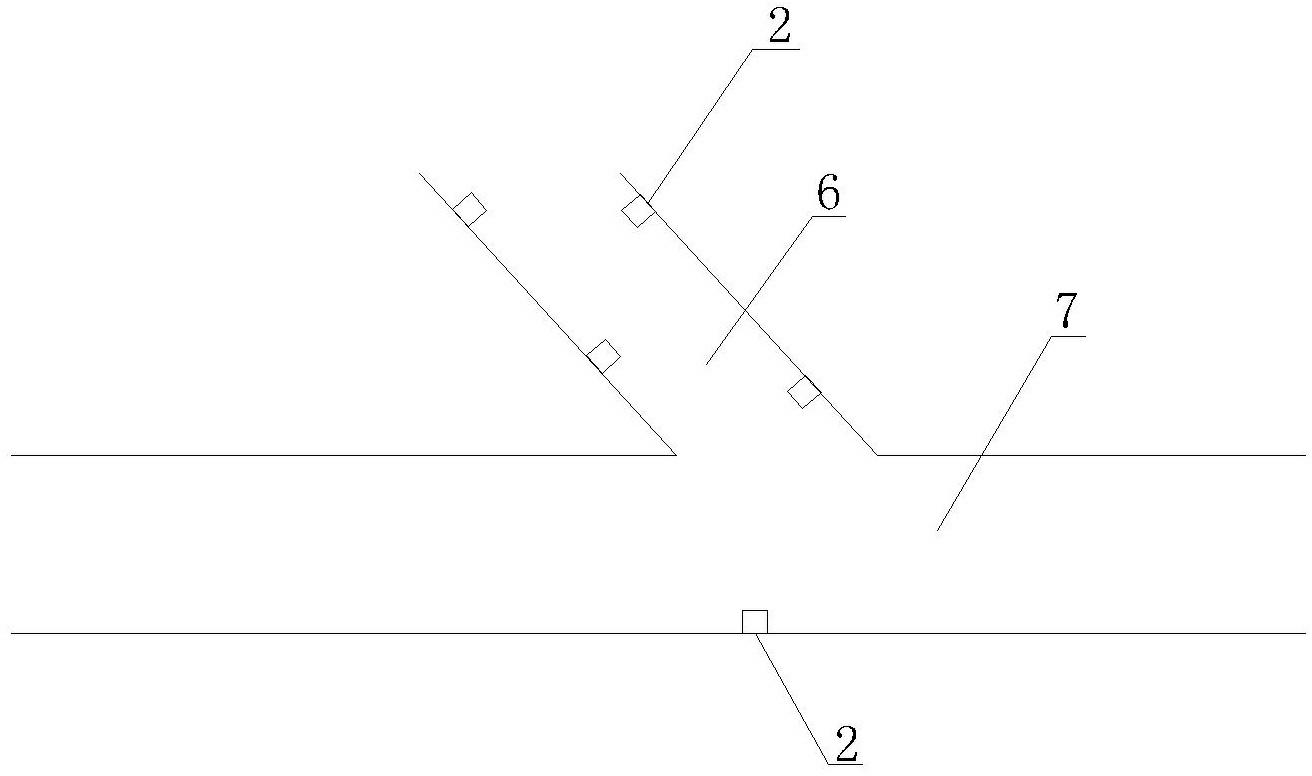

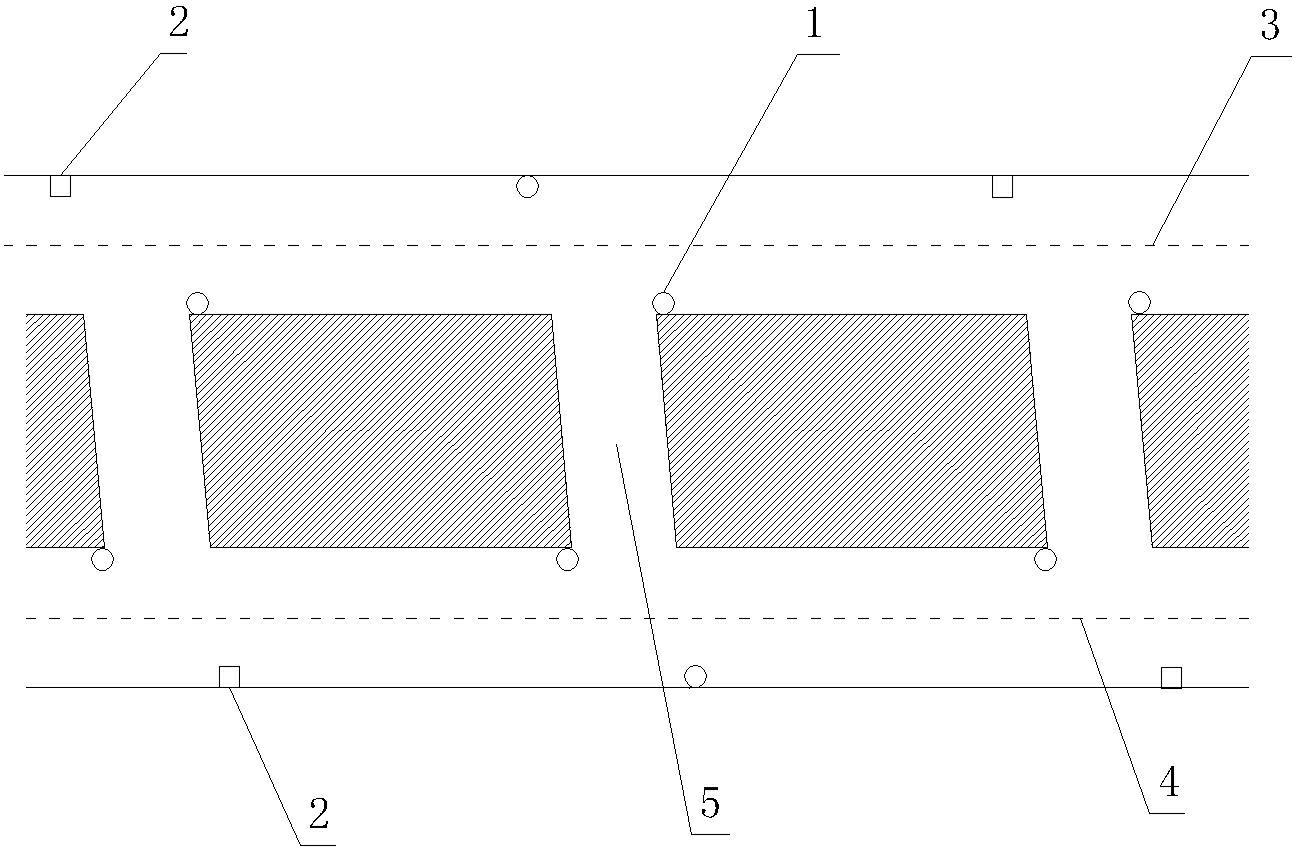

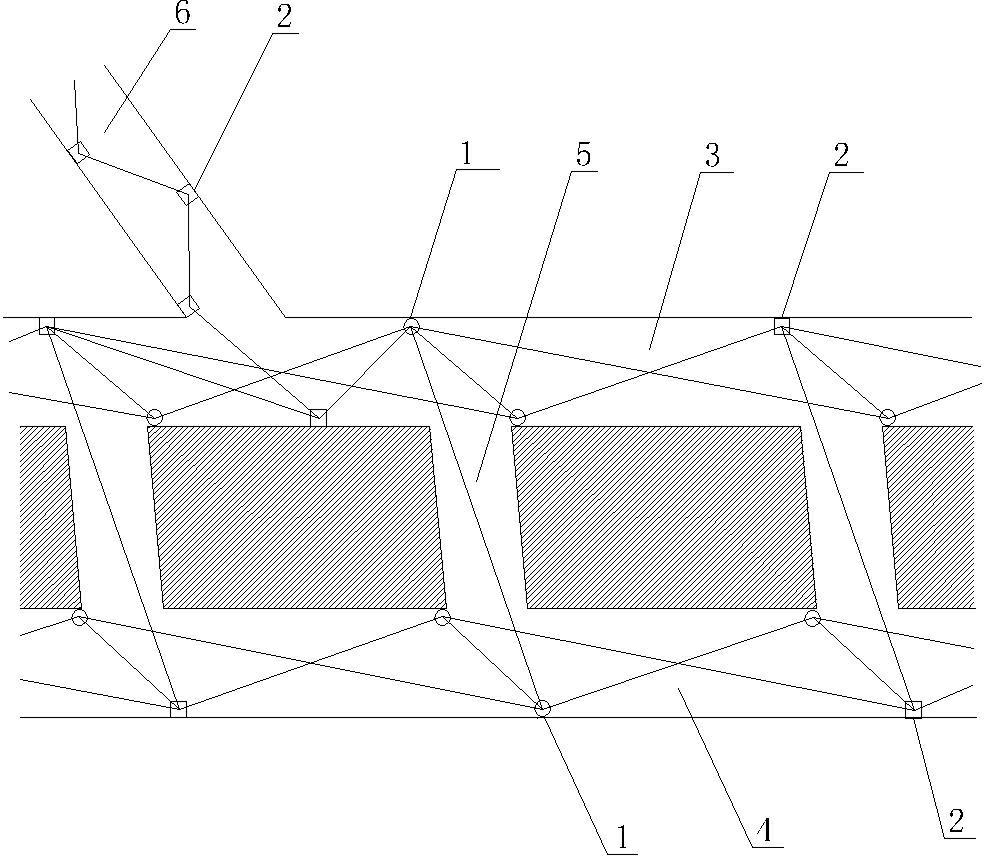

[0043] The invention is applied in the construction plan of segmented construction in the construction of super-long tunnels. Multiple inclined shafts are set along different sections of the main tunnel to increase the excavation section. In addition to excavating from the openings at both ends of the tunnel, a construction team is also set up to excavate from various inclined shafts, divide the long tunnel into several sections, and realize two-way construction of each section; Starting from both ends, the ballastless track is laid in advance in the tunnel segment that has been penetrated. Such a construction plan can not only shorten the tunnel construction period, but also improve construction safety.

[0044] The prerequisite for the laying of ballastless track before the overall penetration of the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com