End supporting frame of tap wrapping machine

A technology of support frame and tape wrapping machine, applied in laying solid insulation and other directions, can solve the problems of inflexible and convenient adjustment, and achieve the effect of simple and convenient support, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

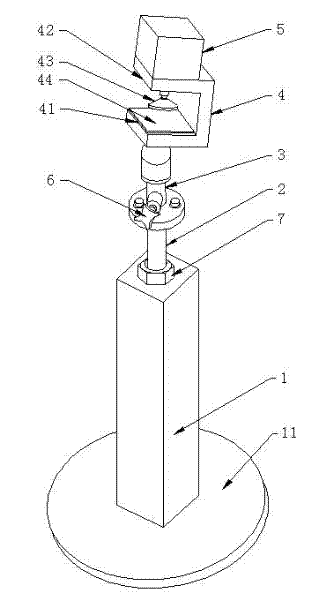

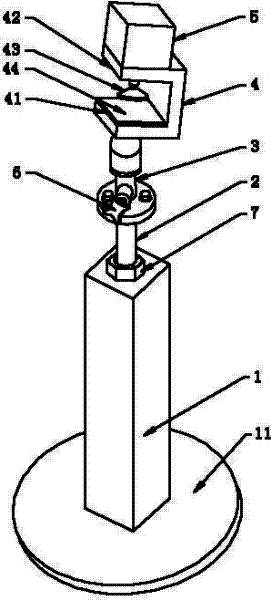

[0016] Such as figure 1 As shown, the taping machine end support frame of the present invention includes a base 1, a screw 2 is arranged on the upper end of the base, one end of the screw 2 is arranged in the base 1, and the other end is connected with the universal joint 3 through threads, and the universal The other end of the joint 3 is connected with the clamp 4 . The gripper 4 is driven by an air cylinder 5 .

[0017] The clamp 4 is a 匚-shaped structure with one side opening, and is composed of three surfaces. The first surface 41 of the two parallel surfaces is connected to the universal joint 3, and the second surface 42 is provided with a chuck 43, which is connected to the universal j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com