Deformation seam template support method

A technology of deformation joints and formwork, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of prolonged construction period, material waste, repeated surface trimming, etc., to save materials and shorten the Simple and convenient effect of construction period, support and dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

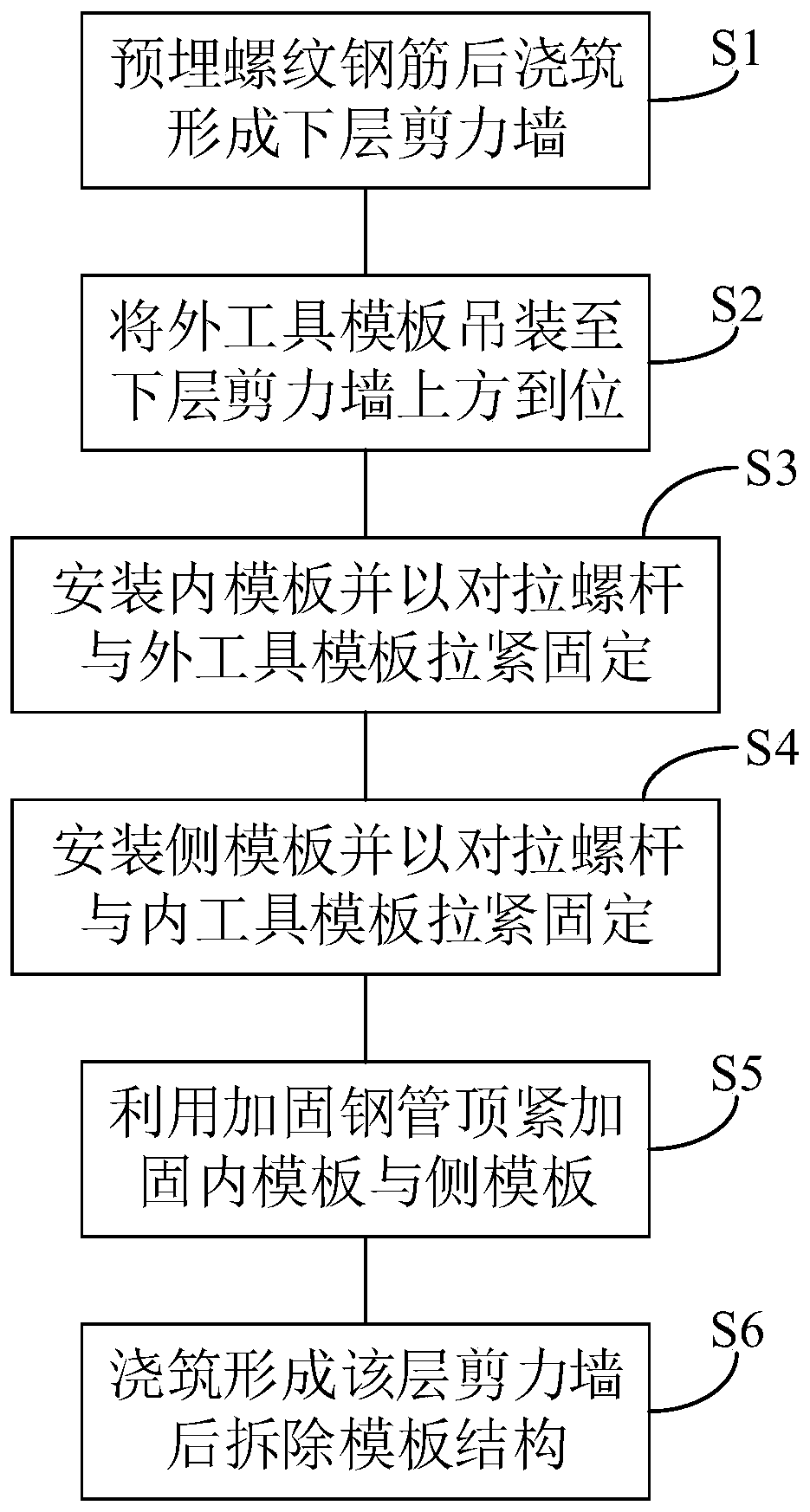

[0036] see Figure 1~5 , this embodiment discloses a method for supporting a deformation joint template, which is used to support a deformation joint with a turning structure, including the following steps:

[0037] S1: Concrete is poured after embedding multiple threaded steel bars to form the lower shear wall. When pre-embedding, the threaded steel bars are distributed high outside and low inside.

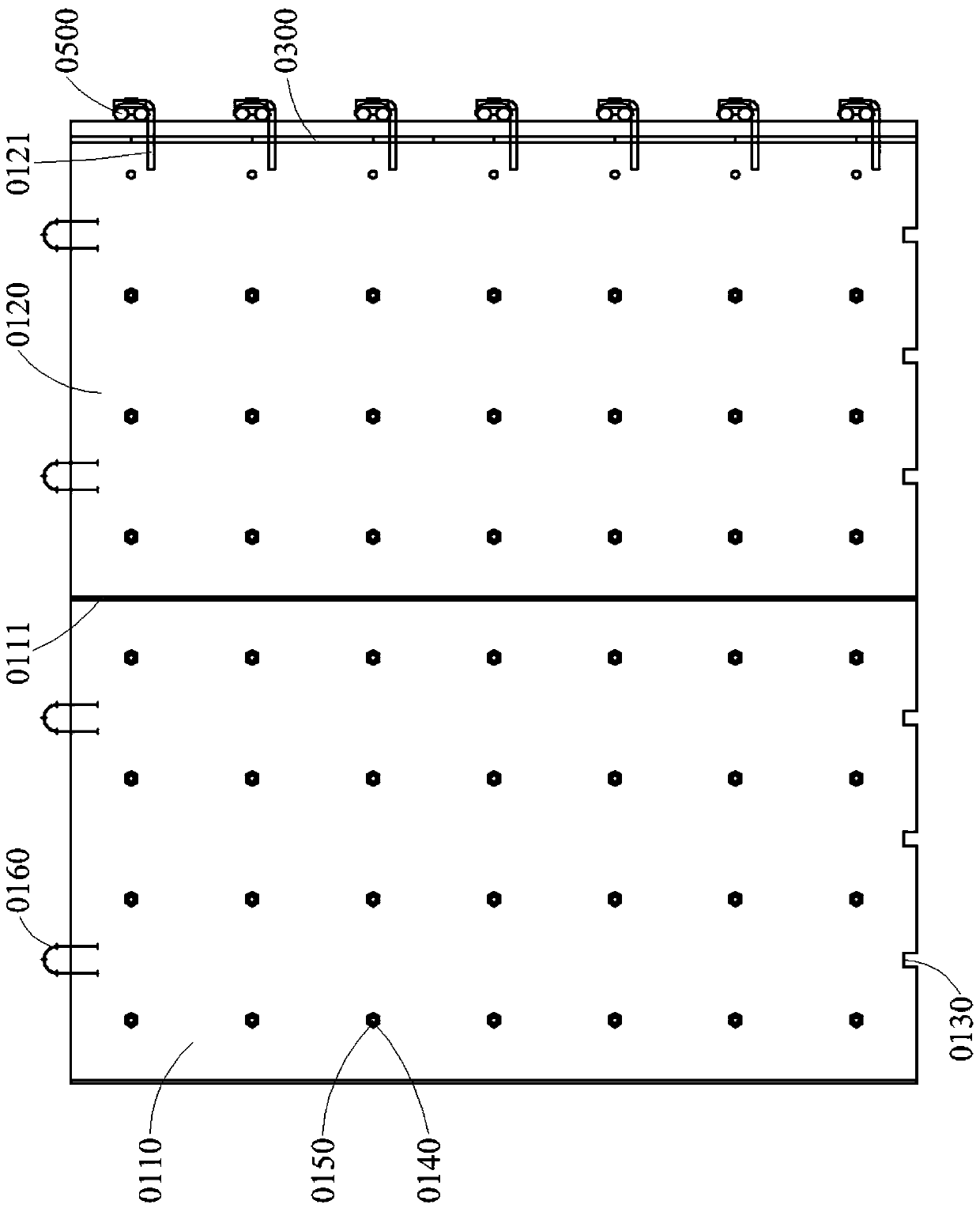

[0038] S2: Hoist the outer tool formwork 0100 above the lower shear wall, so that the support groove 0130 and the threaded steel bar are snapped into place. Exemplarily, when the outer tool formwork 0100 is spliced by a plurality of plates (for example, a shaped plate 0110 and a non-shaped plate 0120), the multiple plates should be hoisted one by one to the corresponding positions on the upper surface of the lower shear wall, so that each The plates are aligned and clamped with the threaded steel bars respectively. Furthermore, the tongue-and-groove 0111 between adjacent pla...

Embodiment 2

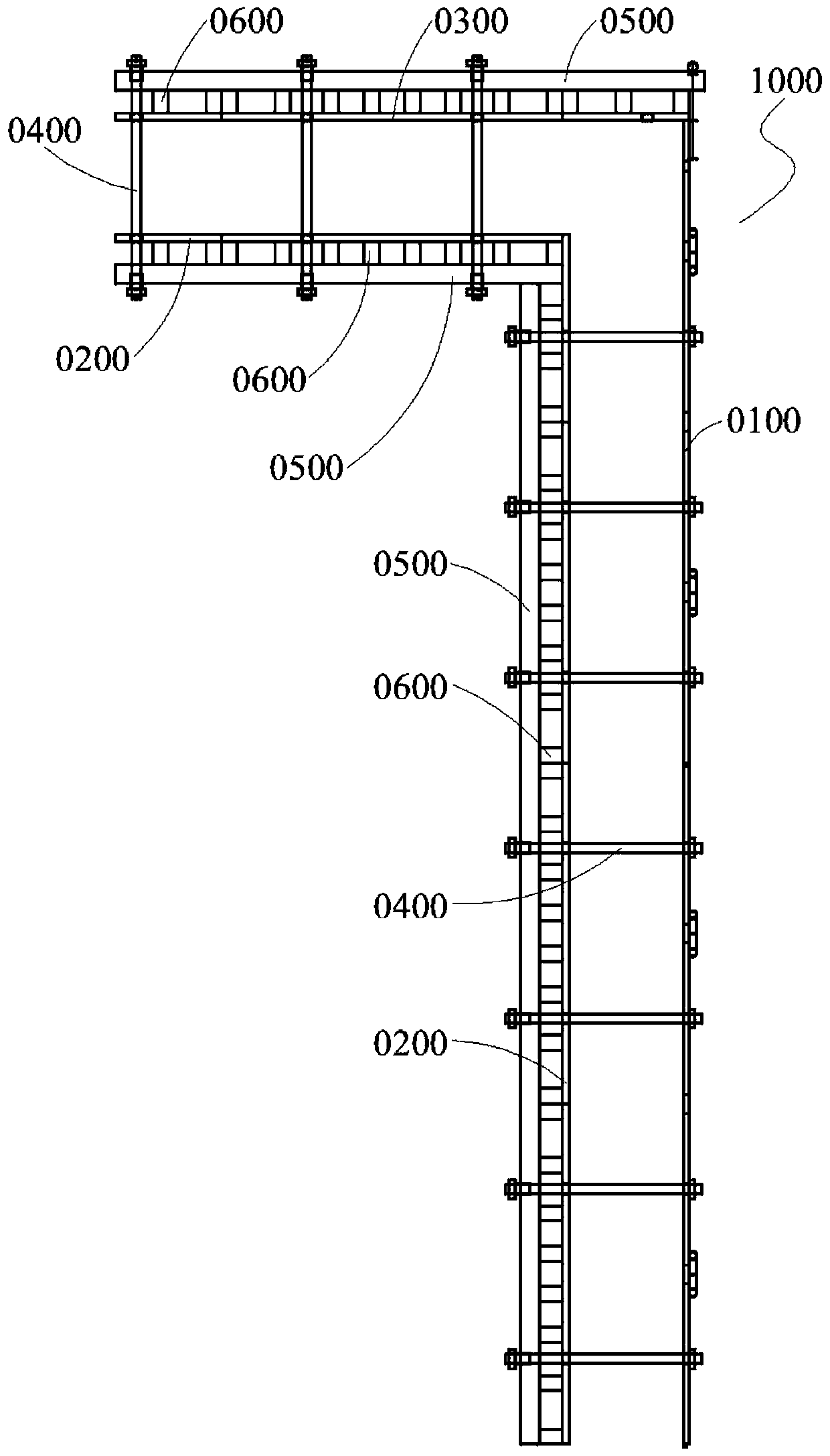

[0046] Please refer to Figure 2~4 , this embodiment further discloses a deformation seam formwork structure 1000, which is used to implement the deformation seam formwork supporting method introduced in Embodiment 1. The deformation seam template structure 1000 includes an outer tool template 0100, an inner template 0200, and a side template 0300 arranged at one end of the outer tool template 0100. The outer tool template 0100 and the side template 0300 are connected to form the outer surface of the deformation seam, and the inner template 0200 is used to form The inner surface of the deformation seam.

[0047] For example, in the application of deformation joints with an L-shaped structure, the inner template 0200 is spliced to form the inner surface of the L-shaped structure, and the outer tool template 0100 is connected with the side template 0300 to form the outer surface of the L-shaped structure. It can be understood that the inner template 0200 can be formed by spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com