Portable assembled steel pile frame for steel bar raw materials and manufacturing method thereof

A raw material and assembly technology, applied in packaging, external frame, transportation and packaging, etc., can solve the problems of not being able to meet the requirements of green construction, generating garbage, and being unable to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is only used to explain the present invention and does not constitute a limitation to the protection scope of the present invention.

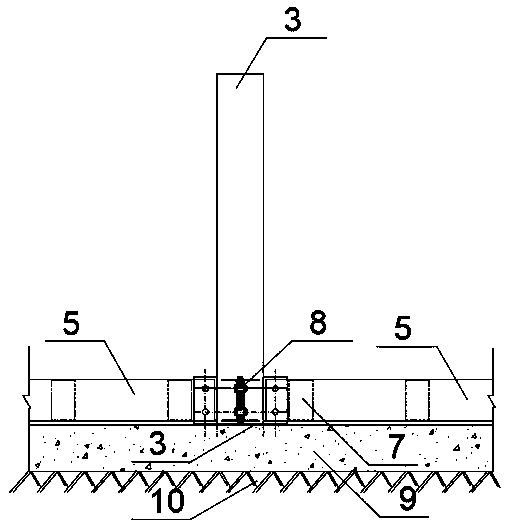

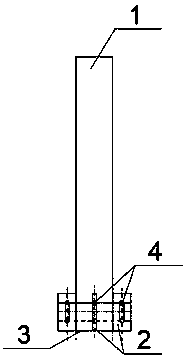

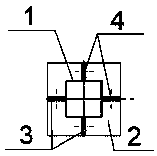

[0028] like Figure 1-3b As shown, a steel stacking rack for portable assembled steel bar raw materials includes special columns for steel stacking racks and special connecting rods for steel stacking racks. Vertically welded with the steel plate seat 3, the two sides of the rib plate 2 are respectively welded to the square steel 1 and the steel plate seat 3, the rib plate 2 is provided with a hole 4 on the rib plate, and the special connecting rod for the steel stacking frame includes channel steel 5 and connecting steel 7 plates , the connecting steel plate 7 is welded on the channel steel 5, the two ends of the channel steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com