Electric shaver

一种剃刀、搭条的技术,应用在电剃刀领域,能够解决导入性能不太好、起毛部难以进入等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

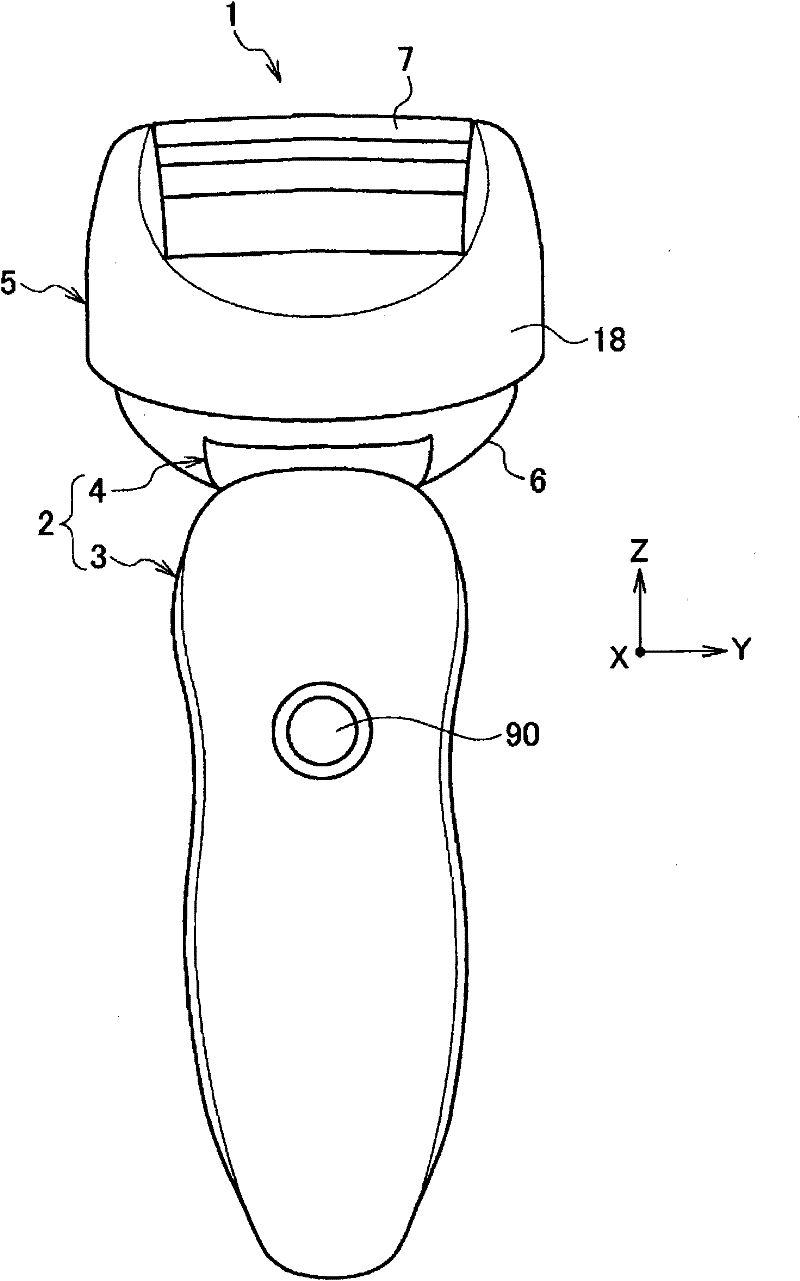

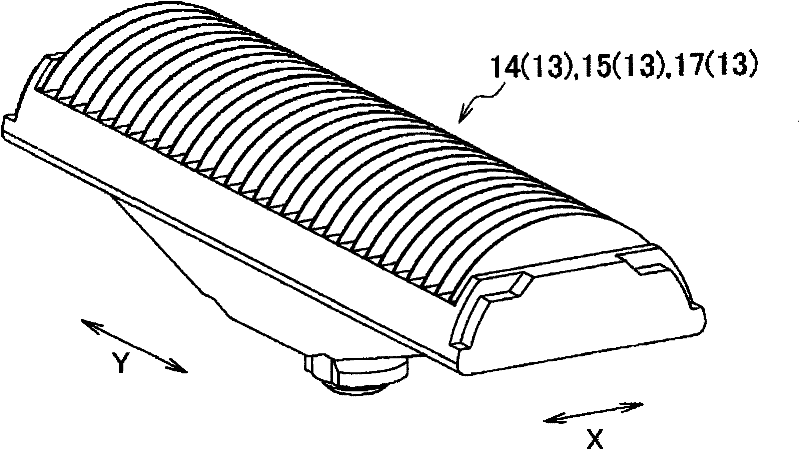

[0033] like figure 1 As shown, the electric shaver 1 of the present embodiment includes a handle 2 to be held by hand, and a head 5 fixed to the handle 2 .

[0034] The handle portion 2 includes a synthetic resin handle body 3 in which a battery (not shown) is incorporated, and a synthetic resin handle connecting portion 4 protruding rearward from the upper surface of the handle body 3 . In addition, at least any one of a known left-right swing mechanism and a known front-back swing mechanism may be provided on the upper surface of the handle connecting portion 4, so that the head 5 can be installed in a swingable manner in the left-right direction or in the front-rear direction. on handle 2.

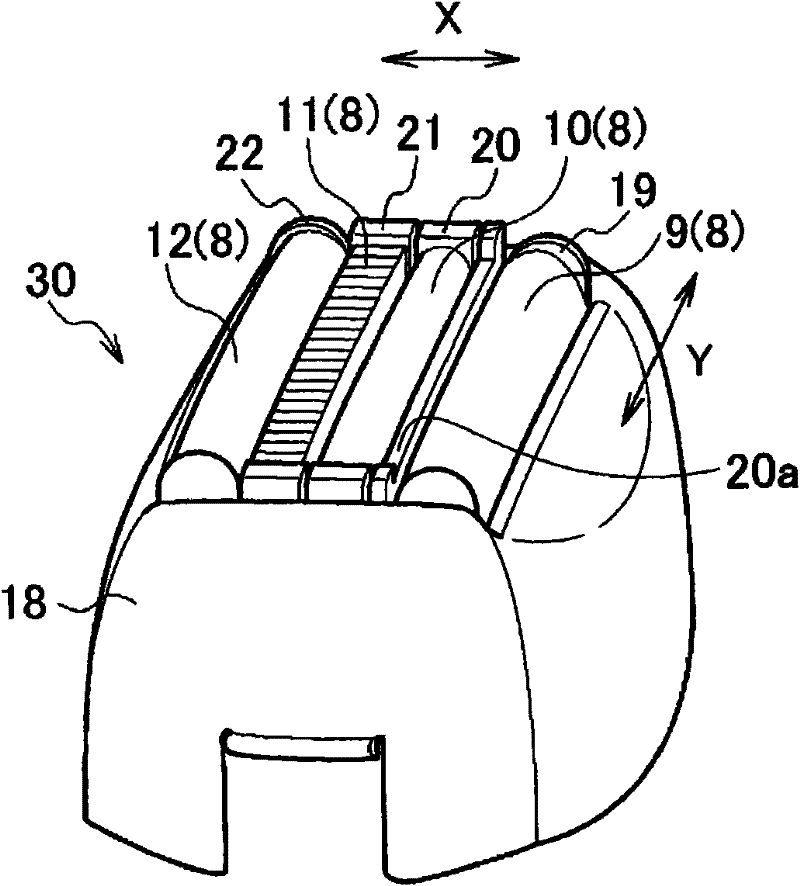

[0035] The head 5 includes a linear head 6 that incorporates a linear motor (not shown) and is connected to the handle connecting portion 4 , and a blade unit 7 attached to the linear head 6 . and, if figure 1 As shown, a switch portion 90 for turning on and off the drive of the line...

no. 2 approach

[0113] As shown in FIG. 22 , the mesh blades 9H, 10H, and 12H of the present embodiment basically have substantially the same configuration as the mesh blades 9 , 10 , and 12 of the first embodiment described above.

[0114] That is, the mesh blades 9H, 10H, and 12H are formed by dividing the long plate-shaped members 9cH, 10cH, and 12cH (see FIG. It is bent and formed in an inverted U-shape along the front-rear direction (shaving direction) X so as to be convex.

[0115] And, the longitudinal direction strap part 42 (the strap part 40) is equipped with: be provided with the raising part (in this embodiment, Side 43c and side 44c are equivalent to the length direction take-up section (raised take-up section) 45 of the big raised section 45c of the raising force of the raised section); The skin contacting surface 45j of the skin contacting surface 45j is near the longitudinal direction strap portion (the first strap portion) 43 on the position of the inner blade 13 side; 45j ...

no. 3 approach

[0126] In this embodiment, an example in which the present invention is applied to a rotary electric shaver will be described.

[0127] The main difference between the electric shaver 1I of this embodiment and the above-mentioned first embodiment is that the inner blade 13I is a rotating blade.

[0128] This electric shaver 1I includes an outer blade 8I, and an inner blade 13I that is disposed inside the outer blade 8I (below the outer blade 8I) and relatively moves relative to the outer blade 8I. The outer blade 8I and the inner blade 13I are each formed in a circular shape, and the inner blade 13I rotates in the rotation direction (direction b) with respect to the outer blade 8I fixed on the main body side. Then, the body hair 71 inserted into the blade hole 50 of the outer blade 8I is cut by the cooperative operation of the outer blade 8I and the inner blade 13I.

[0129] In the present embodiment, a plurality of radially elongated substantially rectangular cutting holes 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com