Down-rotation pushing anti-counterfeiting bottle cap

An anti-counterfeiting bottle cap and screw top technology, applied in the directions of packaging, locking equipment, closing, etc., can solve the problems of unsatisfactory anti-counterfeiting effect and not easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

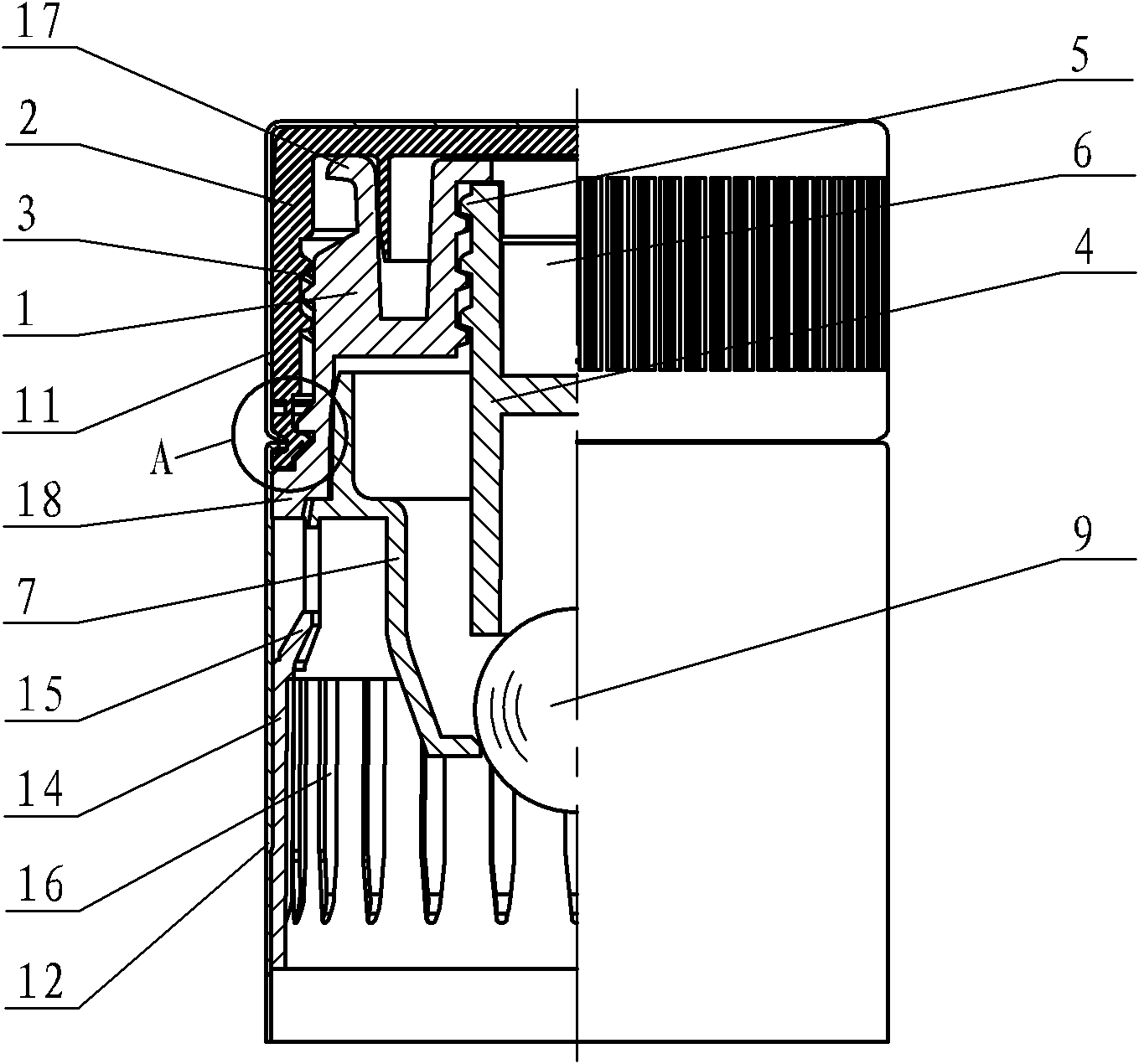

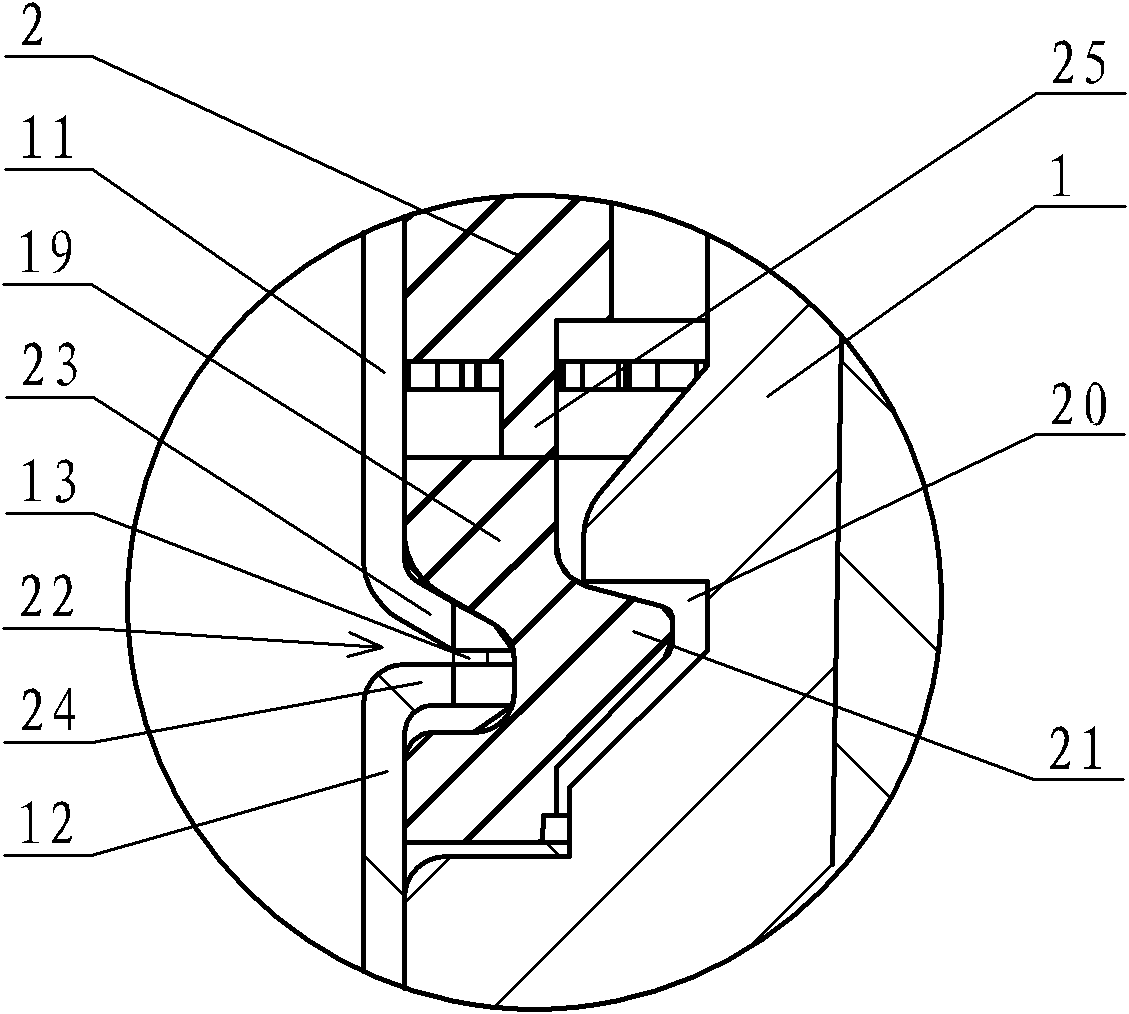

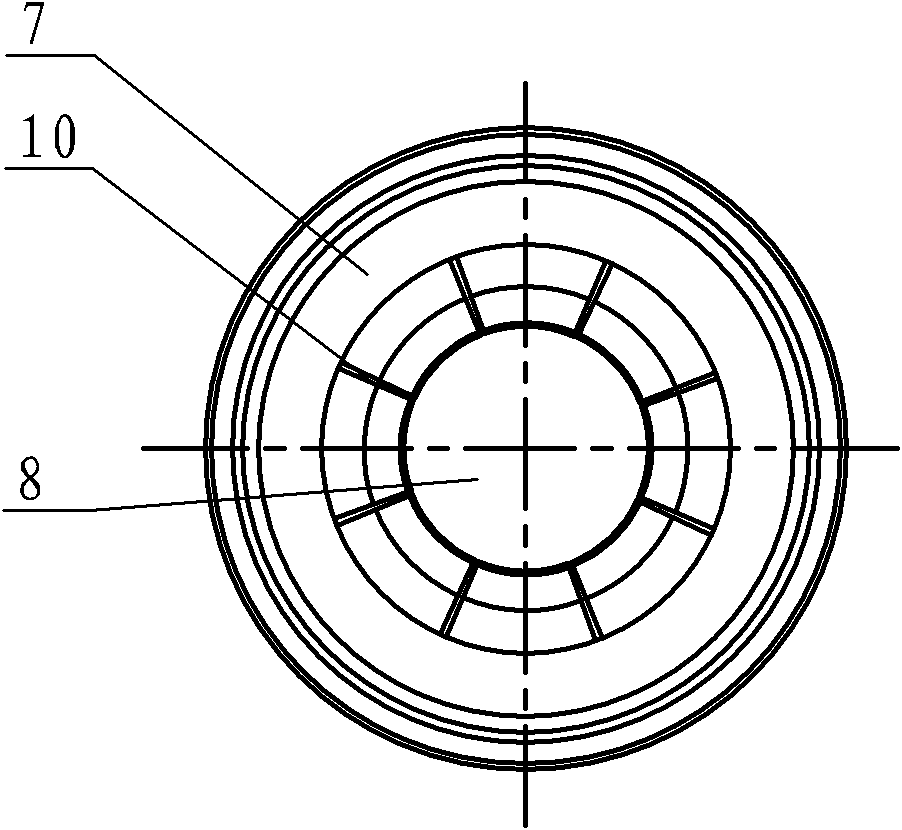

[0030] like figure 1 As shown, the screw top anti-counterfeiting bottle cap of the present invention includes a container sealing part, a pouring spout part 1 and a sleeve part, the container sealing part is an inner cap 2, and the inner cap 2 is connected with the pouring spout part 1 through another threaded part 3, When the other threaded part 3 makes the inner cover 2 rotate relative to the pouring spout part 1, an axial movement is generated. The pouring outlet part 1 is equipped with a lower screw top device 4, which is connected with the pouring outlet part 1 through a threaded part 5, and the threaded part 5 makes the lower screw top device 4 rotate relative to the pouring outlet part 1, and produces axial movement , the upper end surface of the pouring outlet part 1 is provided with a through hole, the through hole is equipped with a lock 6, wherein the lock core is connected with the lower screw top device 4, the lock hole faces the through hole, and the pouring outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com