Visual flame detection system of gasifier and control method of system

A technology of a fire detection system and a control method, which is applied to combustion methods, combustion chambers, safety devices of combustion chambers, etc., can solve the problems of gasifier flameout, inability to visually observe gasifier flame combustion, and false alarms, etc. Simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

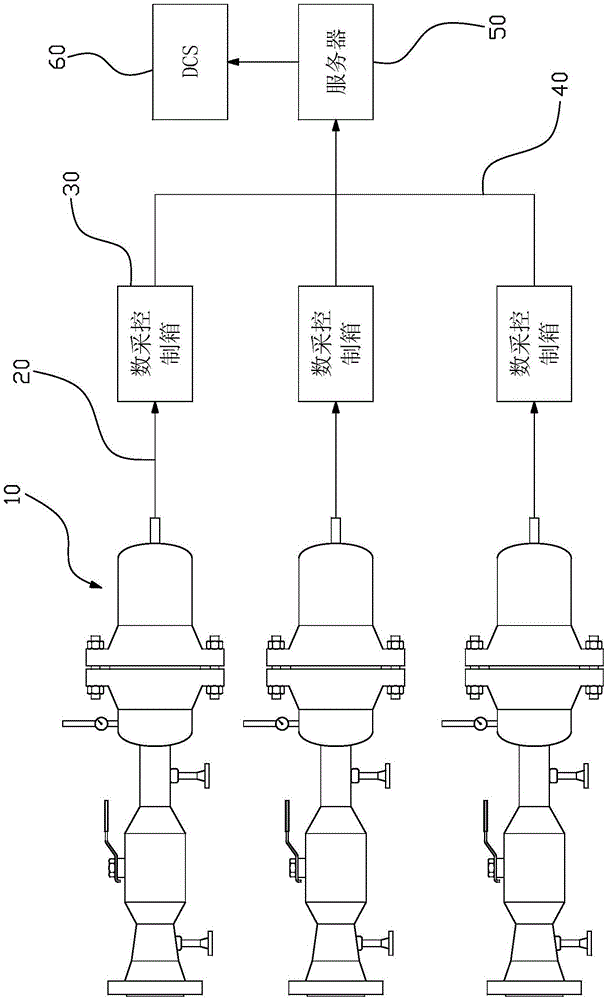

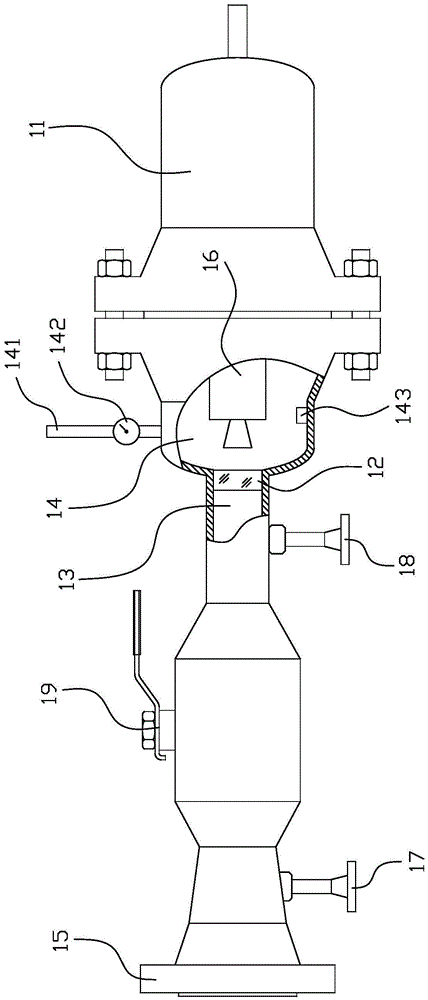

[0011] Combine below Figure 1 to Figure 2 , the present invention is described in further detail.

[0012] refer to figure 1 , a visual flame inspection system for a gasification furnace, including a detection probe 10 arranged on the furnace body, the detection probe 10 is used to obtain image or video information in the furnace and output it to a data acquisition control box 30 through a cable 20, and the data acquisition control box 30 performs analog-to-digital conversion on the received image or video information, and outputs it to the server 50 through the cable 20 or optical cable 40, and the server 50 processes the received information to obtain the flame temperature field distribution and video images and display them. By setting the detection probe 10, the image or video information in the gasifier can be obtained directly, and the flame temperature field distribution and video image can be obtained through the processing of the image or video information by the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com