Manual twin screw lifting platform

A twin-screw lifting and platform technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of limited use, need power supply, and high cost, and achieve the effects of convenient and safe operation, easy positioning, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

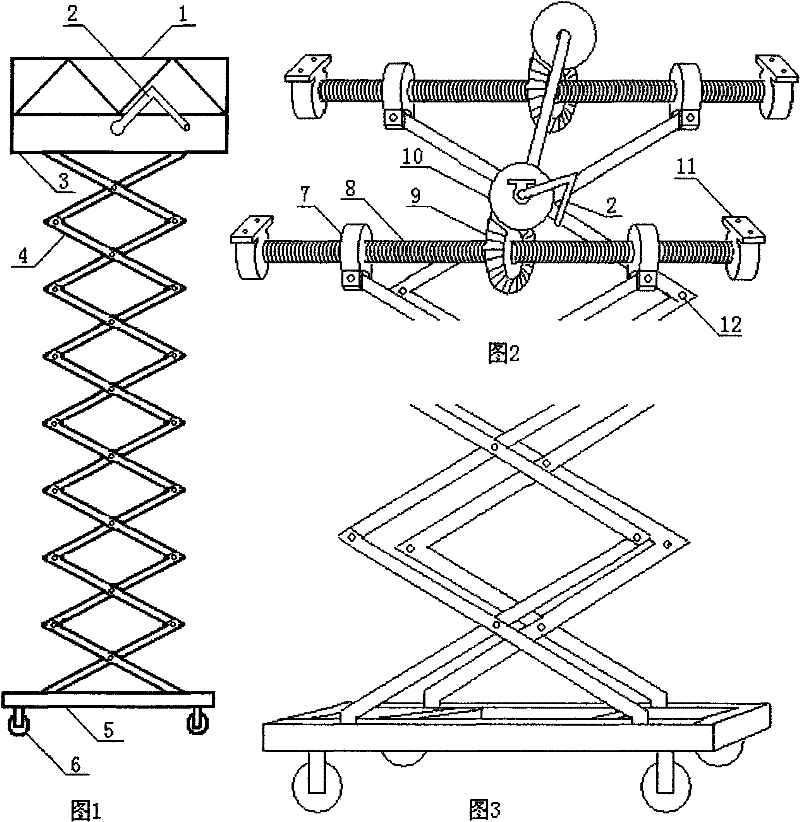

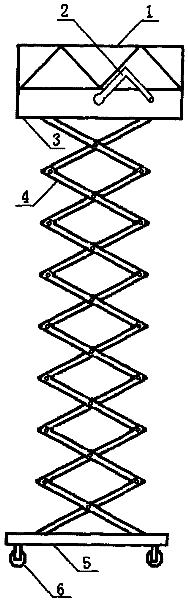

[0023] As shown in the figure, a screw 8 is fixed on the bearing seat 11 through a bearing, and a driving bevel gear 10 is arranged in the middle of the screw 8, and the passive bevel gear 9 meshes with the driving bevel gear 10 on the output shaft of the power source, and the screw Threaded slide block 7 is respectively installed on both sides of upper bevel gear, and nut slide block 7 is connected and fixed on the top of two scissors with bearing pin 12, and the slide block of scissors 4 lower ends is placed in the sliding groove of base 5.

[0024] In this way, the operator is supported on the platform and shakes the crank handle with his hands in the direction, and the rotation of the bevel gear causes the nut slider 7 installed at both ends of the screw 8 to move to the middle at the same time, and the shears fixed on the nut slider 7 through the pin shaft 12 The fork 4 gradually closes with the movement of the nut slider, so that the platform 3 rises steadily, lifts the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com