Apparatus for producing a spunbonded fabric

A non-woven, spunbond technology used in textiles and papermaking, melt spinning, nonwovens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

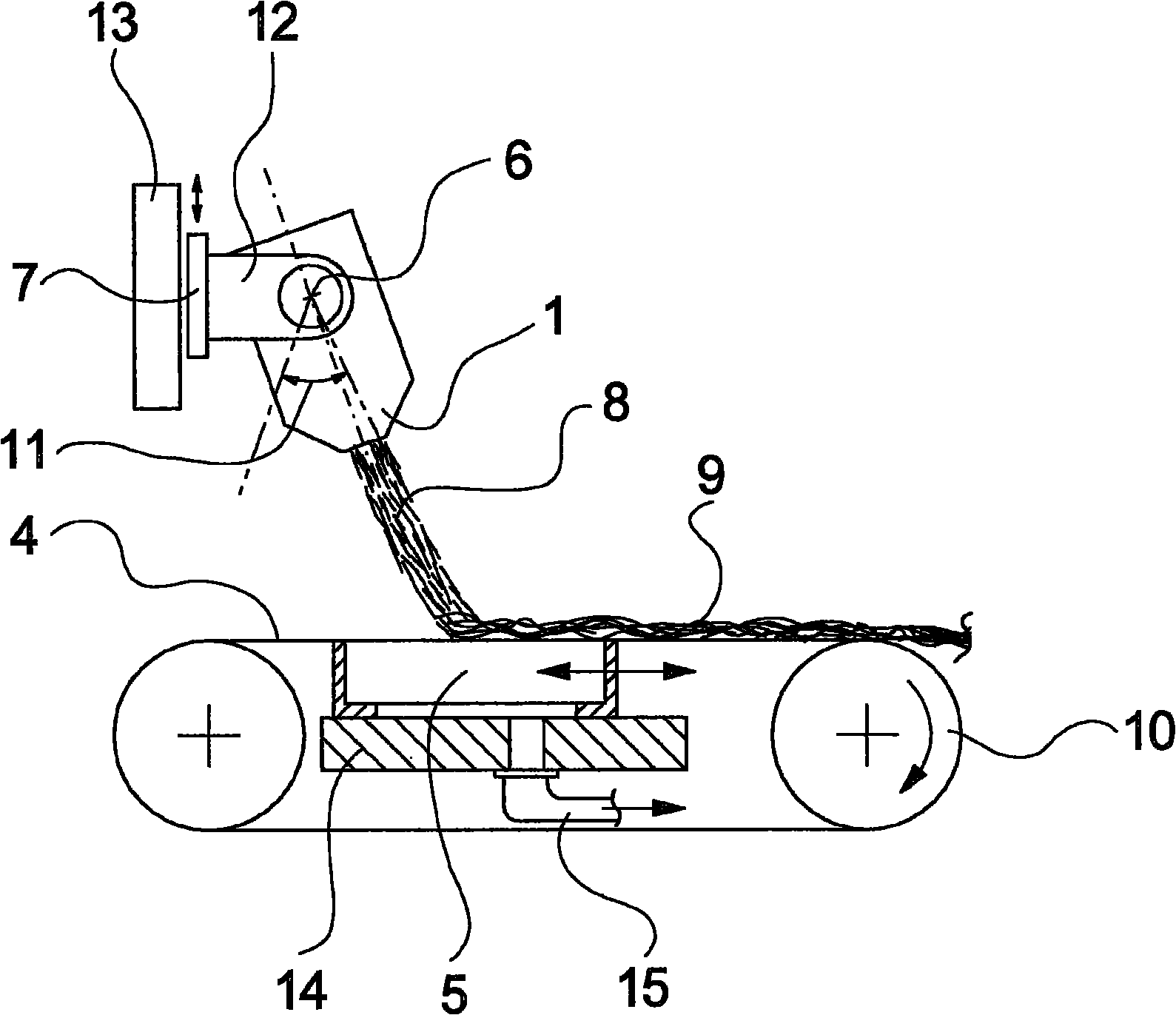

[0024] exist figure 1 A side view of an apparatus for producing spunbonded nonwoven fabrics according to the present invention is shown in .

[0025] A spinning beam (not shown here) and a blowing device are integrated in the pivoting unit 1 in such a way that the filament curtain 8 is delivered on the underside of the pivoting unit 1 . The filaments 8 impinge on the mesh / sieve belt 4 , which is driven by a drive 10 . Due to the high speed at which the filaments 8 impinge on the mesh belt 4, a planar configuration is produced, which is carried away by the mesh belt 4 as a spunbonded nonwoven fabric 9 and delivered to another processing device ( not shown here). Below the point at which the filaments 8 impinge on the mesh belt 4 , a suction box 5 is arranged which is displaceable in the conveying direction of the mesh belt 4 . For this purpose, the suction box is mounted on a support 14 which is connected to the suction structure 15 . Thus, on the one hand, the area of lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com