Patents

Literature

49results about How to "Small regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

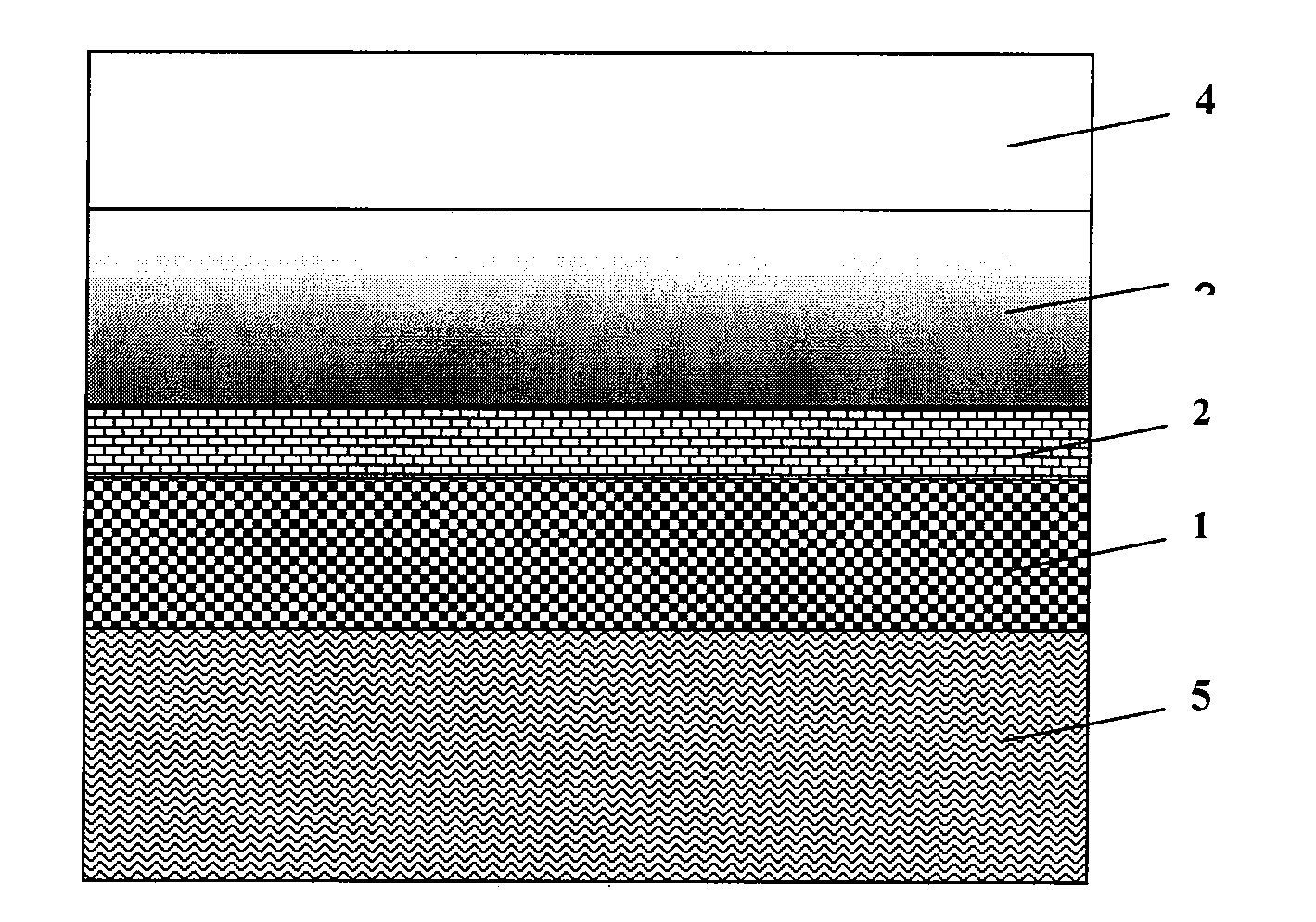

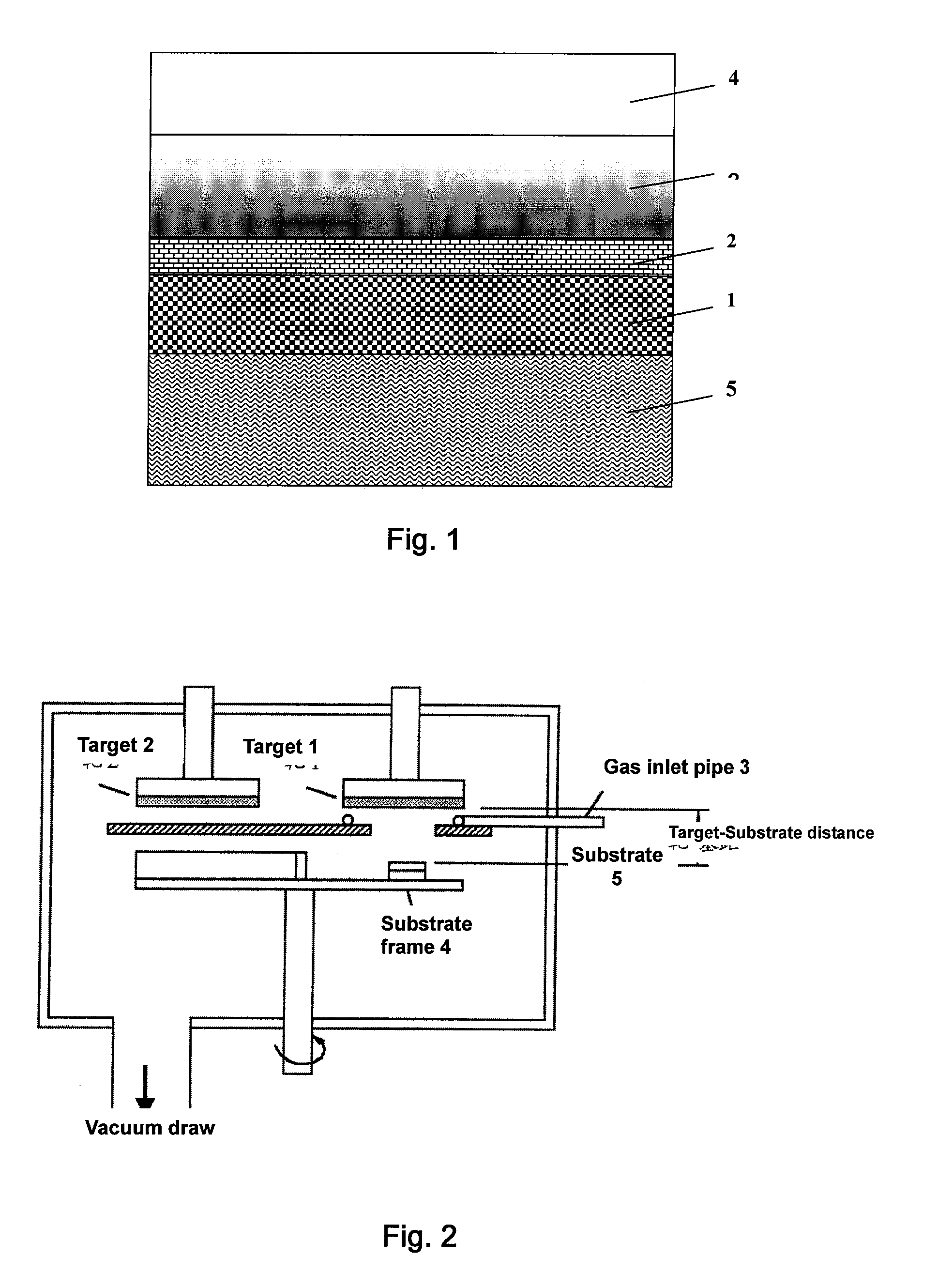

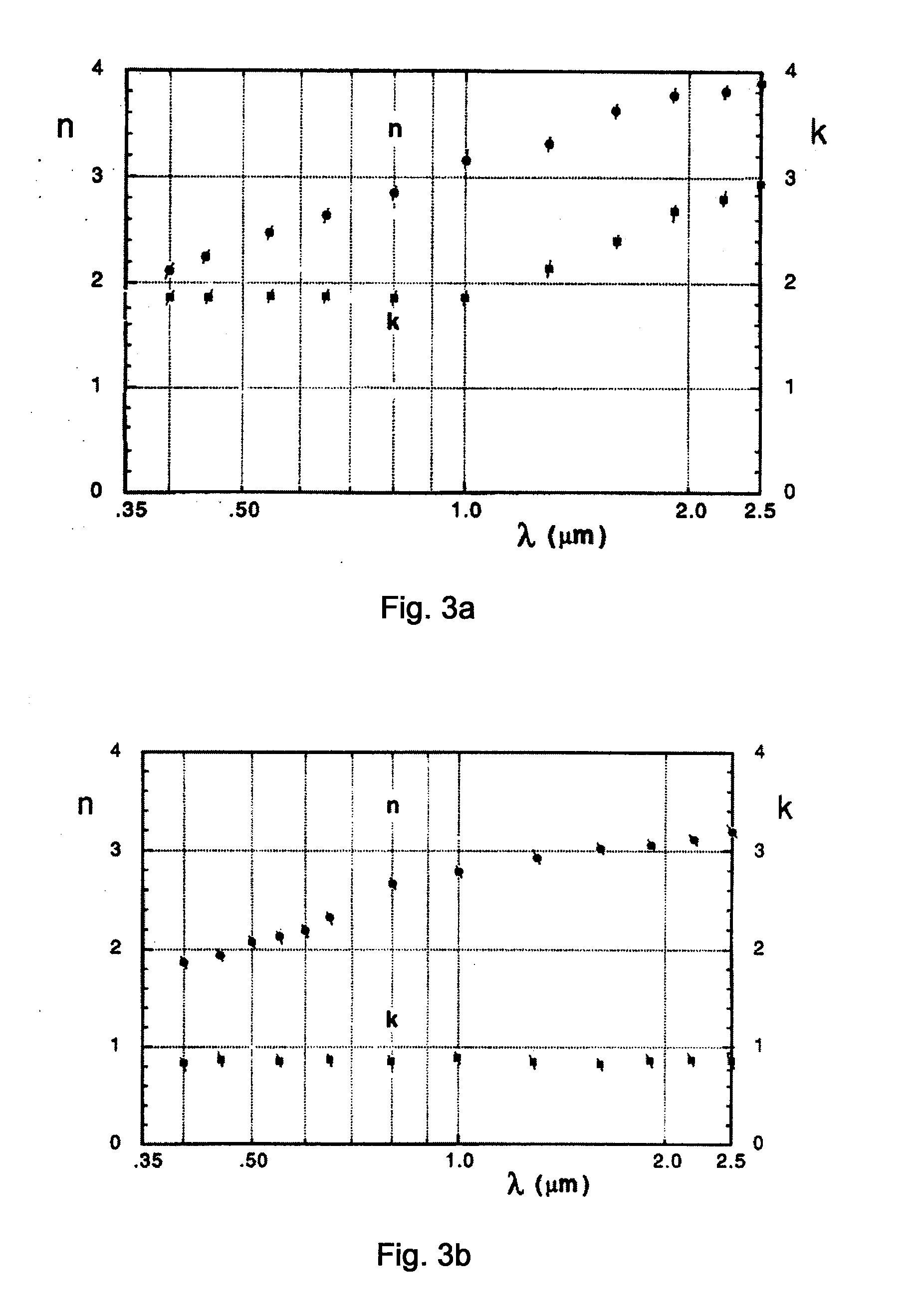

Light selective absorbing coating and its process

InactiveUS20100035034A1Easy to controlExcellent property of corrosion resistance and workability and compatibilitySolar heat devicesSynthetic resin layered productsCoating systemNitrogen

The present invention relates to a light selective absorbing coating and a production process thereof. The light selective absorbing coating consists of a composite material film deposited by reaction of iron chromium alloy and a non-metal gas with vacuum deposition technology. Said non-metal gas comprises gases of nitrogen and oxygen elements. The present invention also relates to a solar energy heat collecting element or solar energy selective absorbing coating system comprising said light selective absorbing coating and a production process thereof. The present invention further relates to use of said composite material film as a light selective absorbing coating of a solar energy heat collecting element or of a solar energy selective absorbing coating system.

Owner:SHENZHEN COMMONPRAISE SOLAR

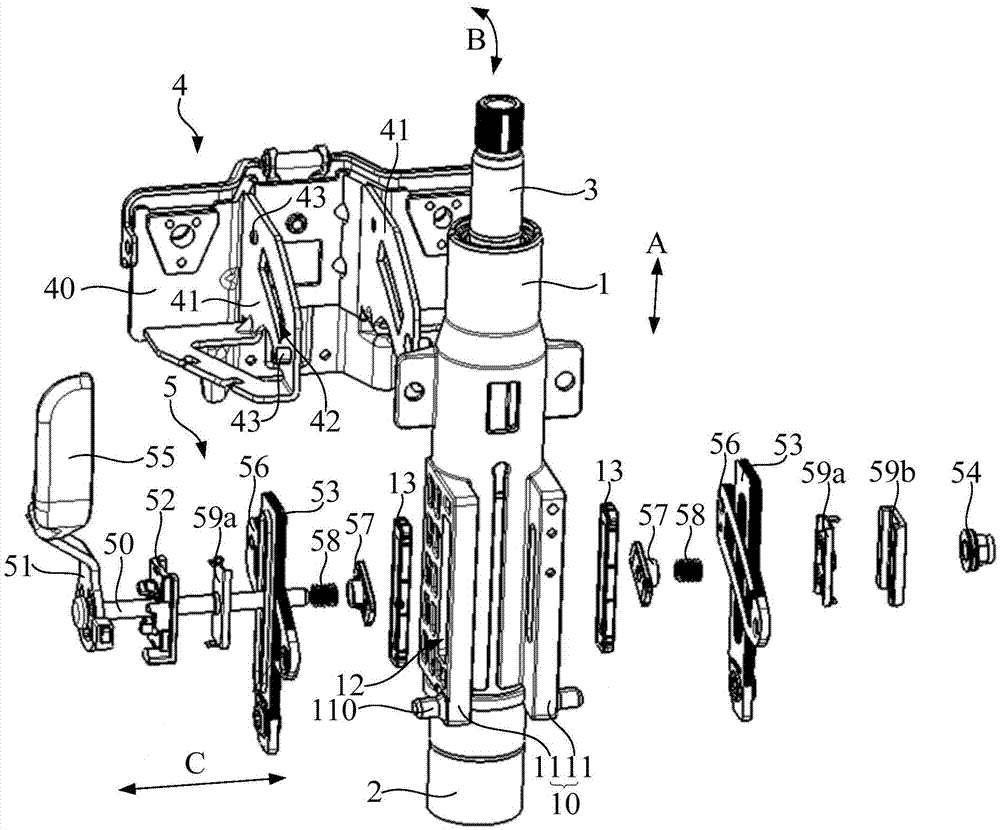

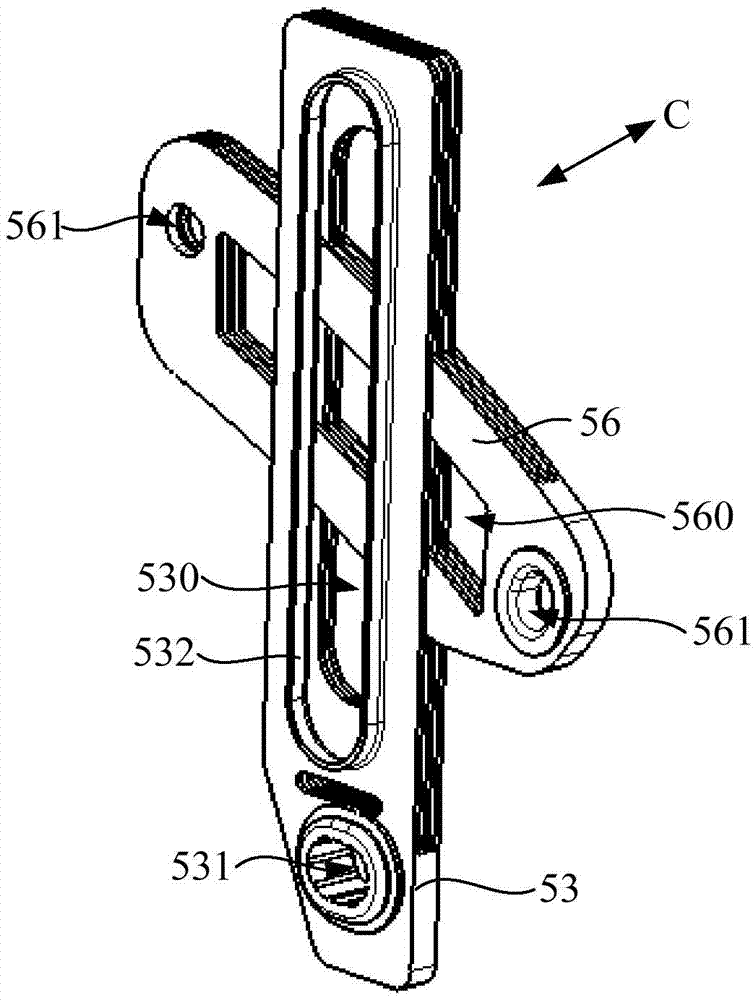

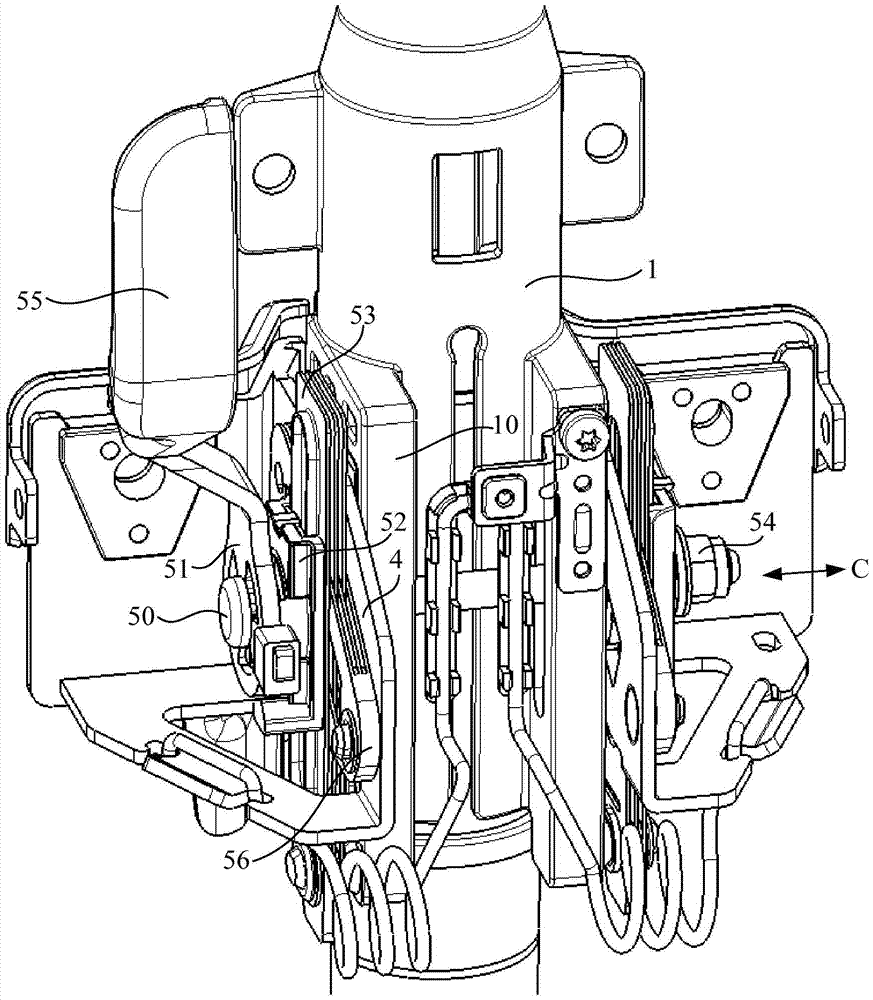

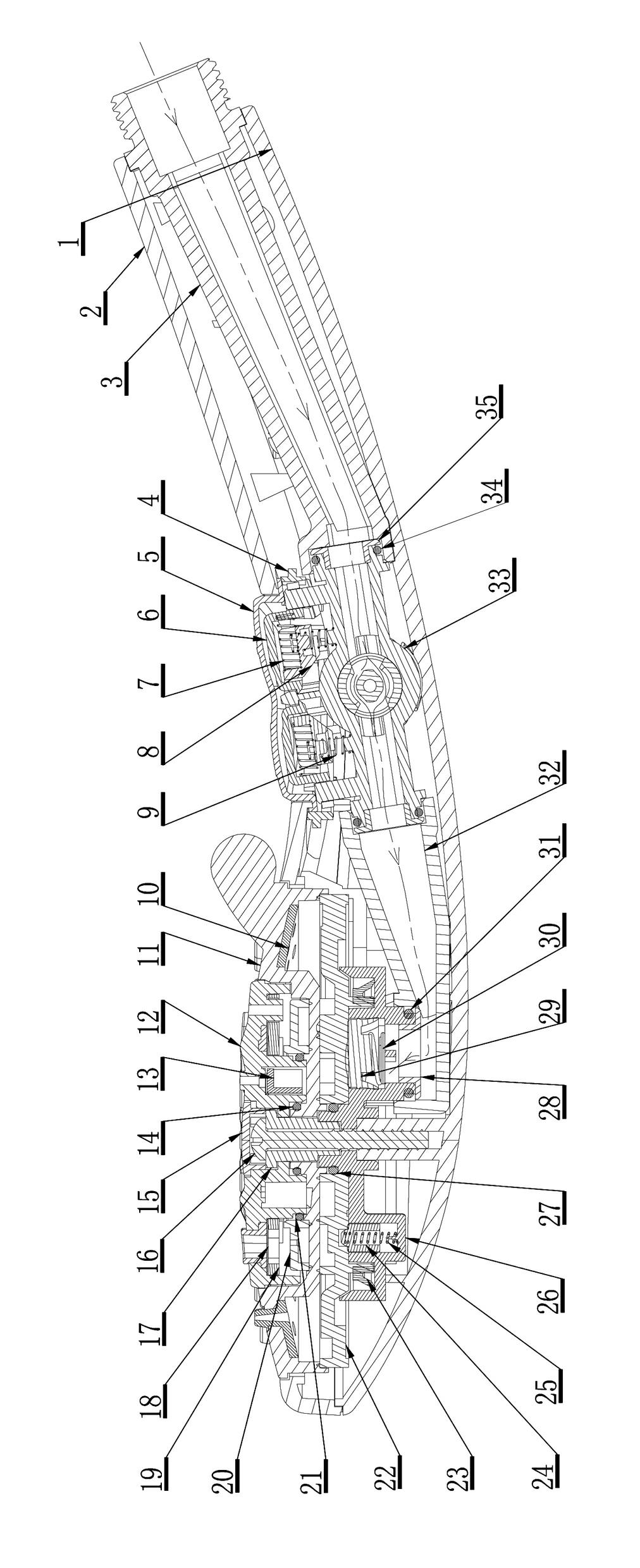

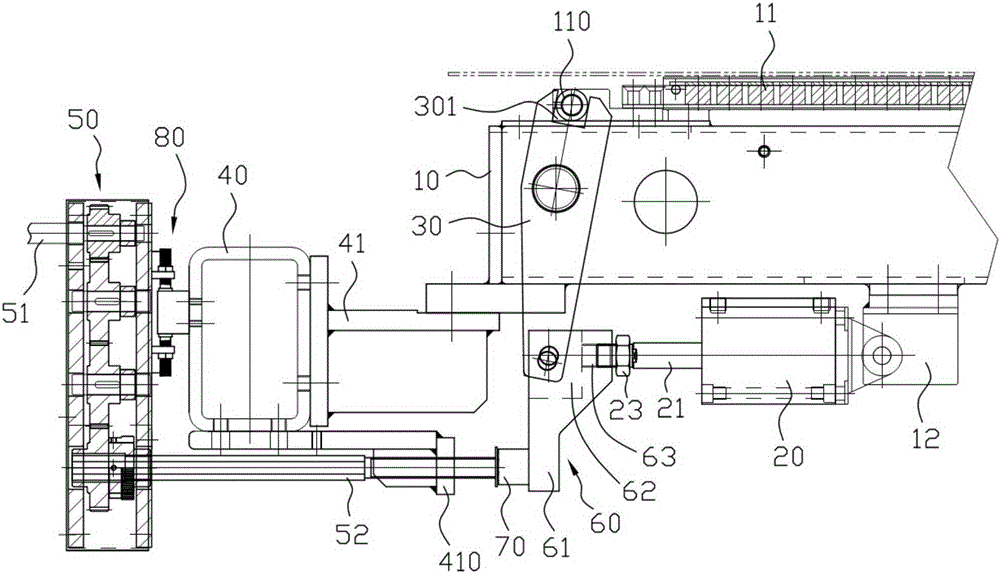

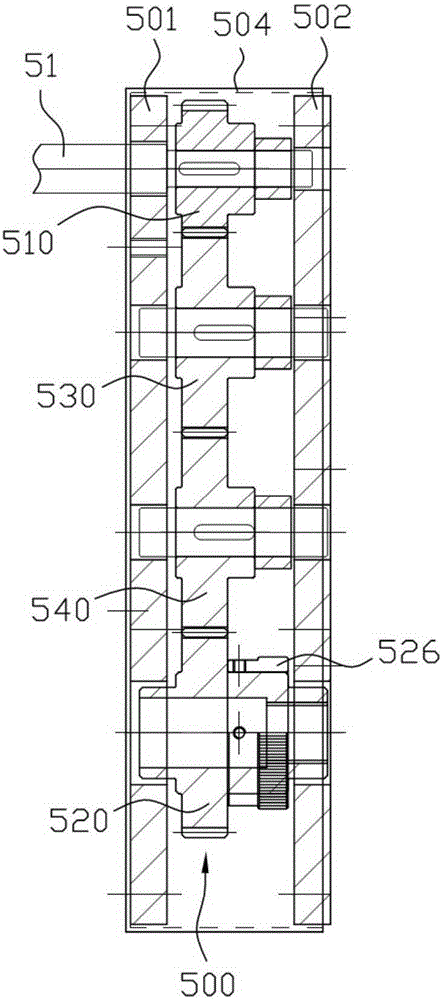

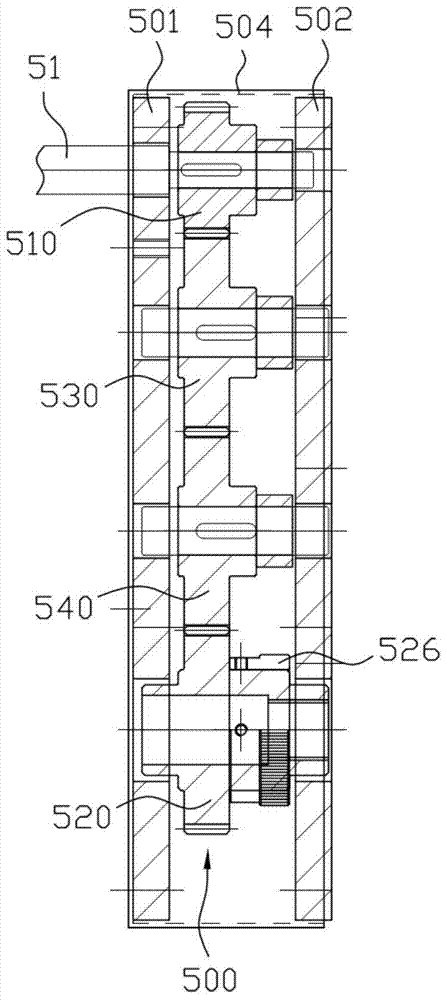

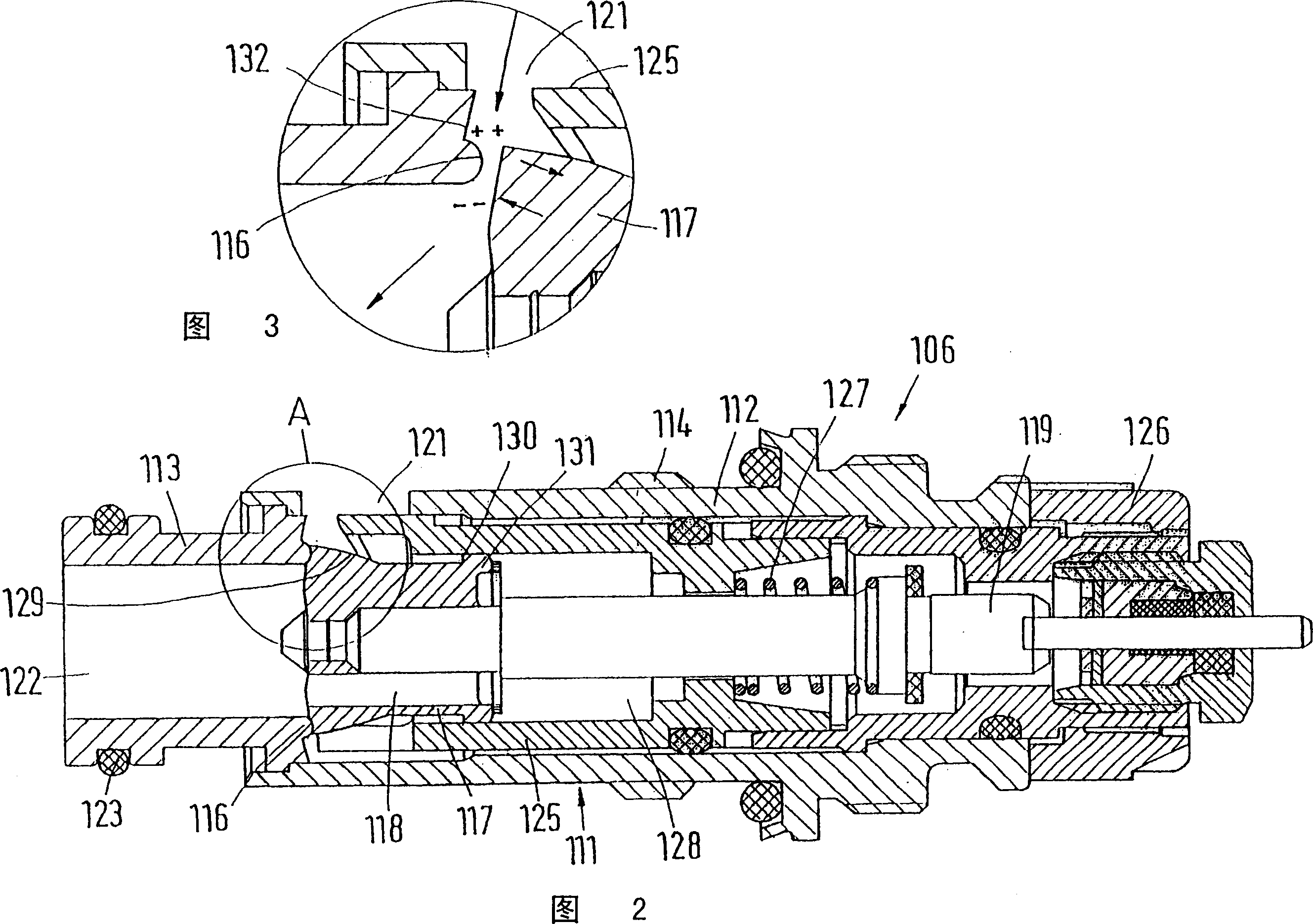

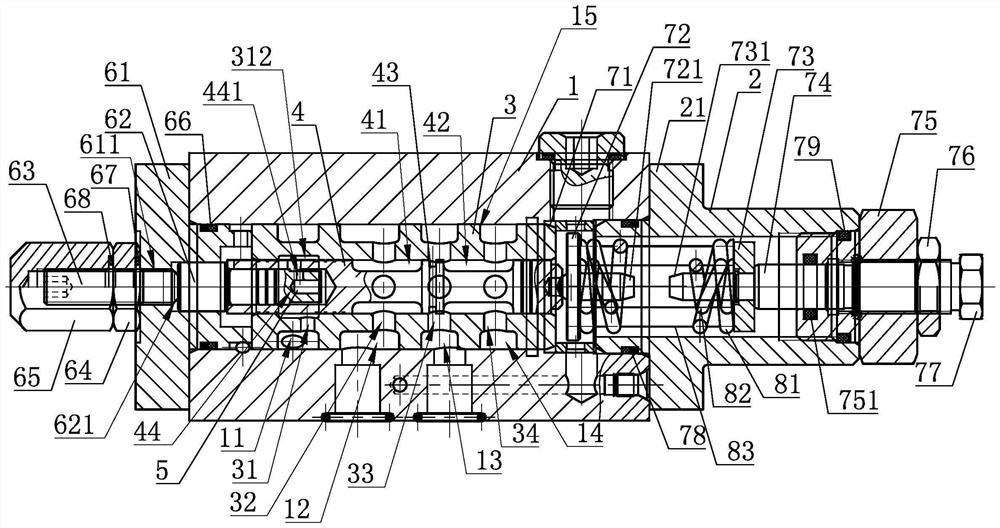

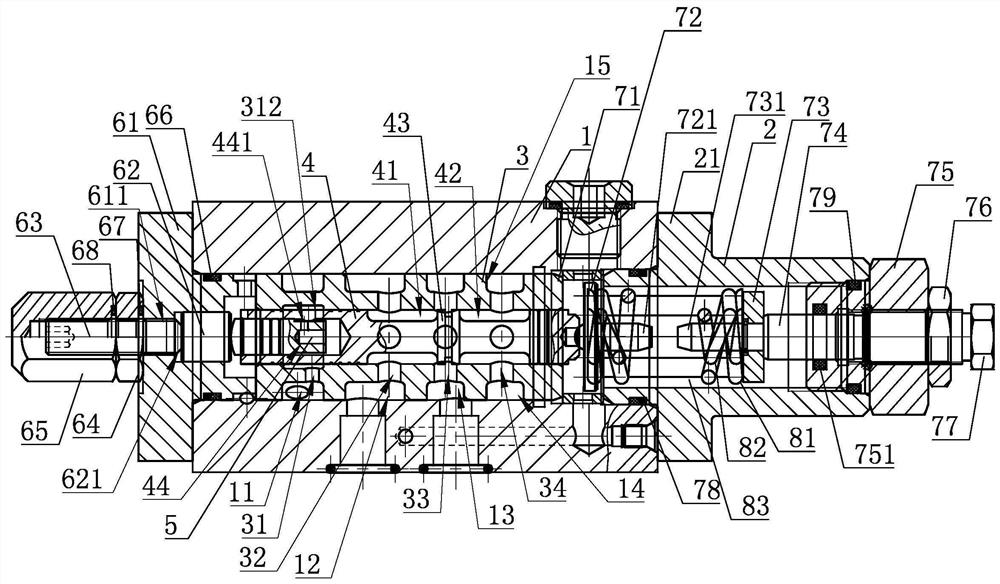

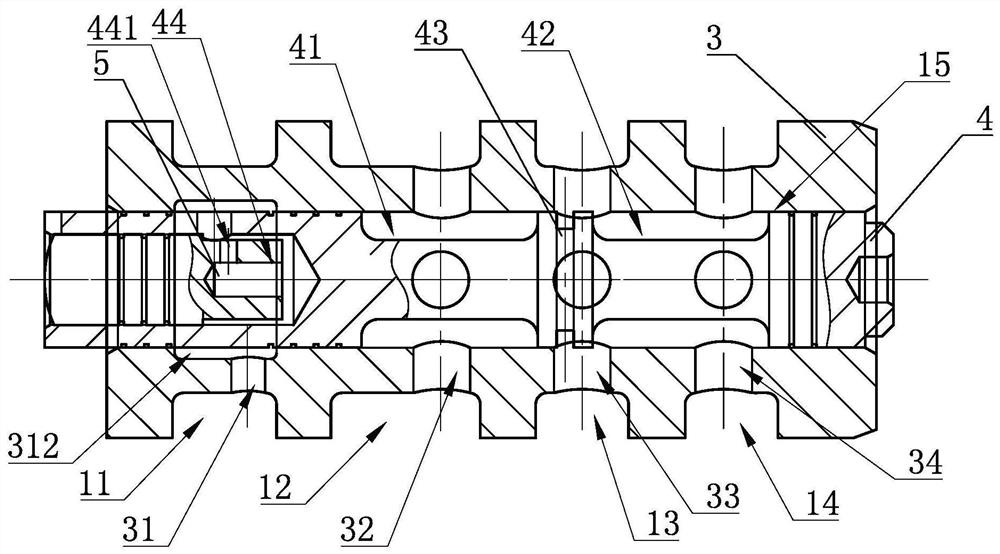

Vehicle, steering system of vehicle, and adjustable steering column of vehicle

ActiveCN106976475ALarge locking forceHigh locking reliabilitySteering columnsSteering columnSteering system

The invention relates to a vehicle, a steering system of the vehicle, and an adjustable steering column of the vehicle. The adjustable steering column comprises a mounting support, an upper column tube and a locking and releasing control assembly, wherein the mounting support is used for being fixed to a vehicle body and is provided with clamping arms which are provided with first through holes; a fixing support is fixedly arranged on the outer wall of the upper column tube, used for being fixed to the clamping arms and provided with second through holes; the locking and releasing control assembly comprises a supporting rod penetrating through the first through holes and the second through holes, first adjusting pieces, second adjusting pieces, first friction pieces and limiting pieces, and the supporting rod is sequentially sleeved with the first adjusting pieces, the second adjusting pieces, the first friction pieces and the limiting pieces in the axial direction; the first adjusting pieces are fixed to the supporting rod, the supporting rod is sleeved with the second adjusting pieces and the first friction pieces in a spaced mode, the first friction pieces are provided with third through holes where the supporting rod can penetrate, and the limiting pieces are static relative to the supporting rod in the axial direction; and the clamping arms and the fixing support are oppositely arranged in the axial direction and located between the first friction pieces and the limiting pieces in the axial direction. Locking force of the adjustable steering column in the locked state is increased, and locking reliability of the steering column is improved.

Owner:SAIC MOTOR

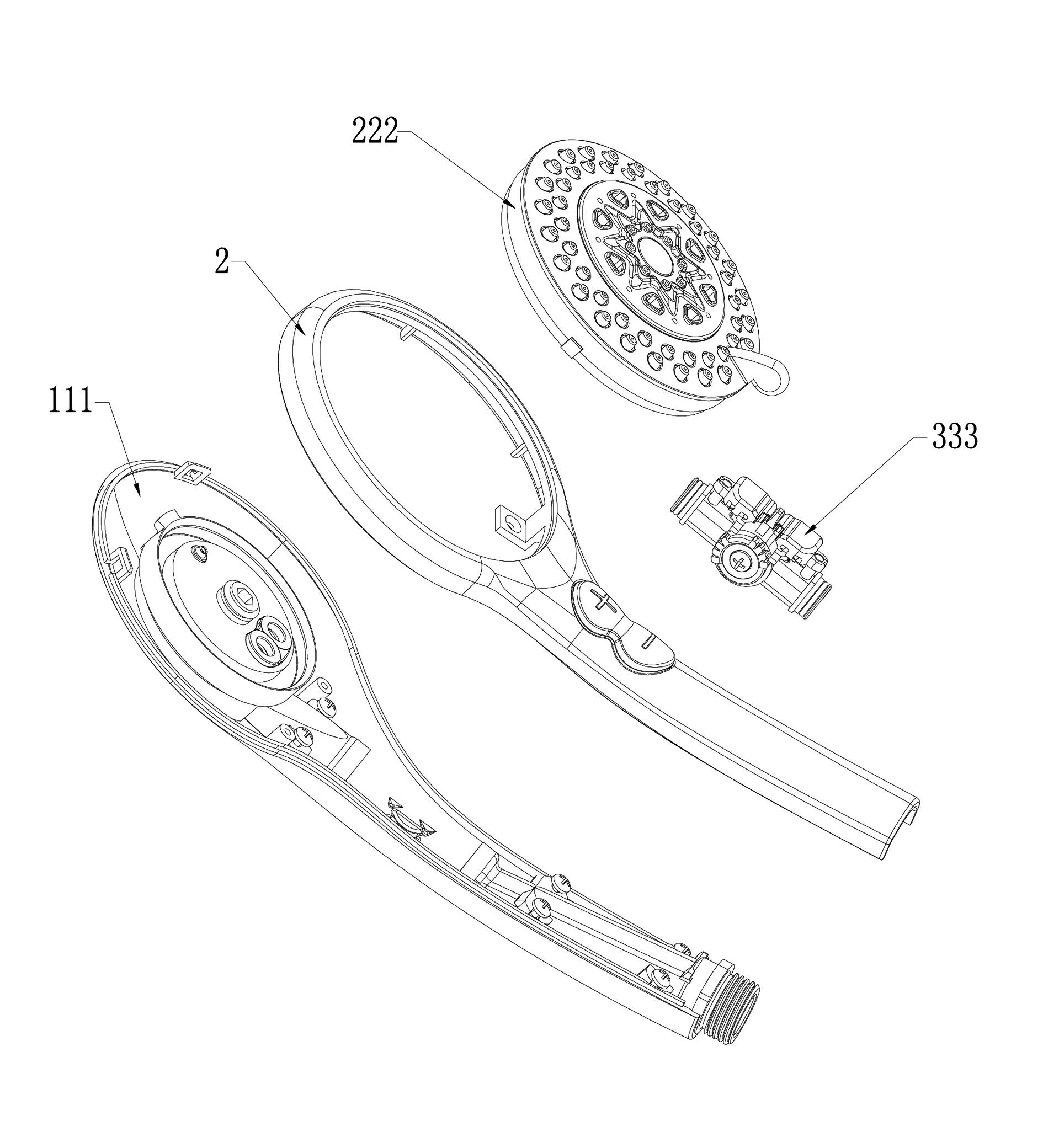

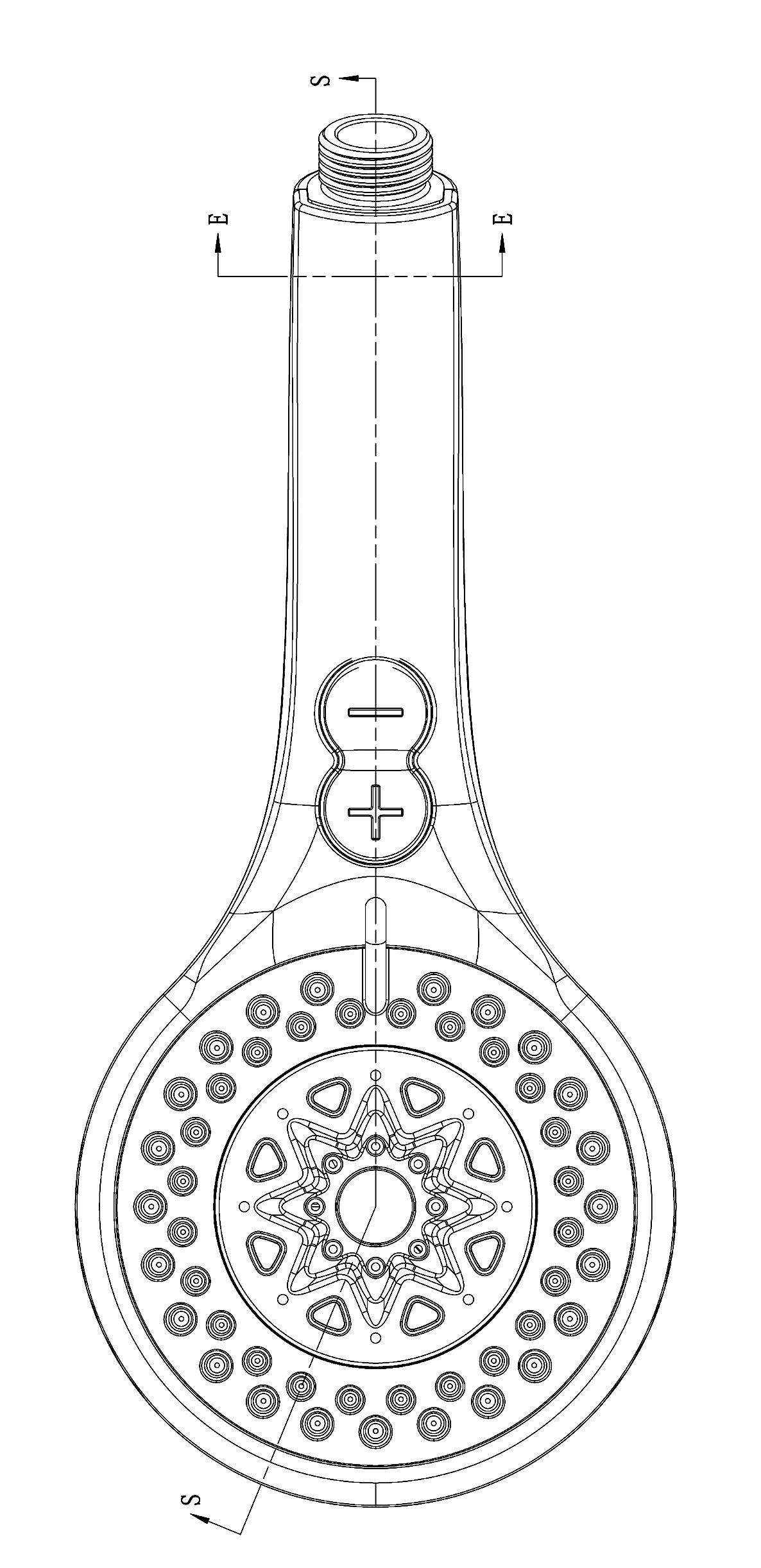

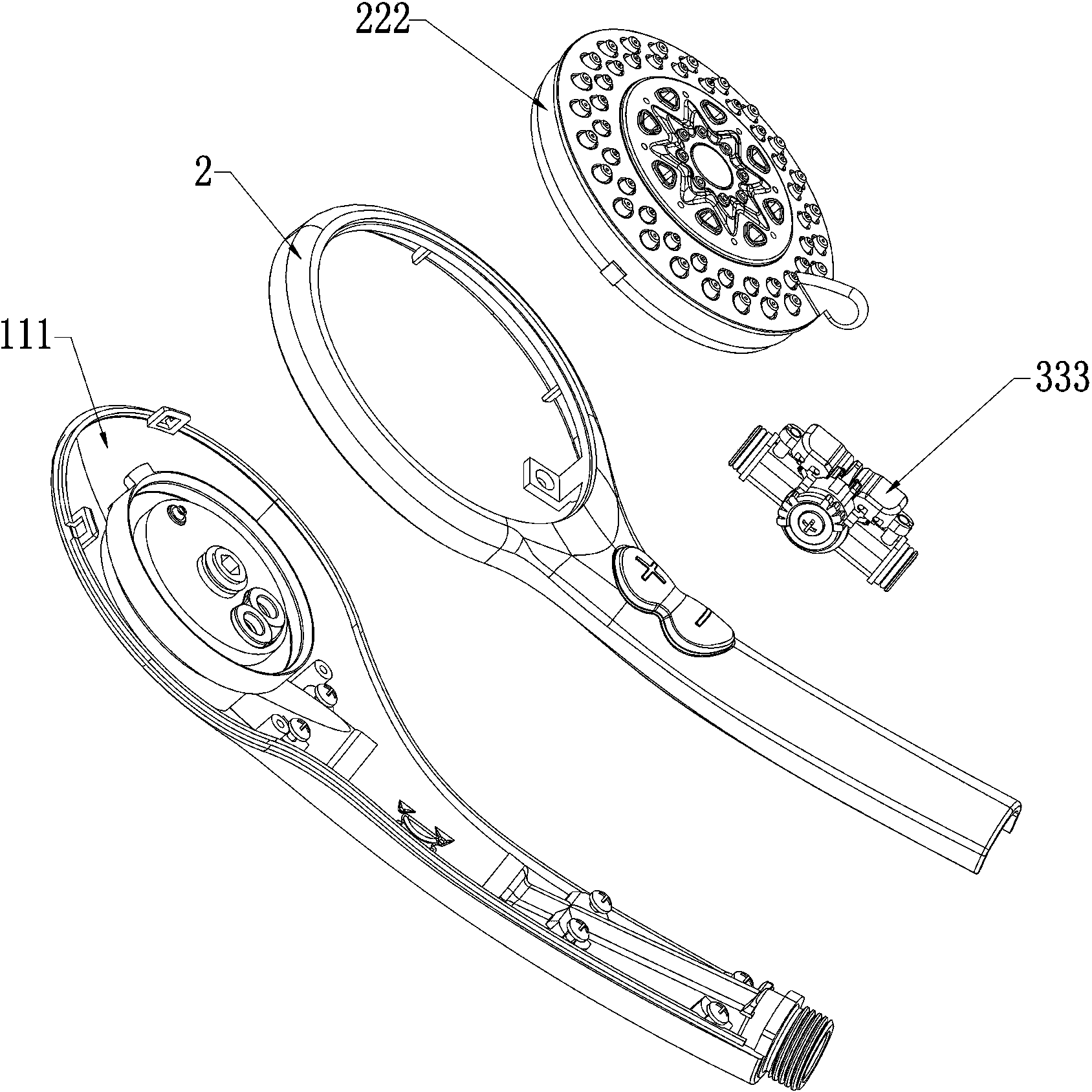

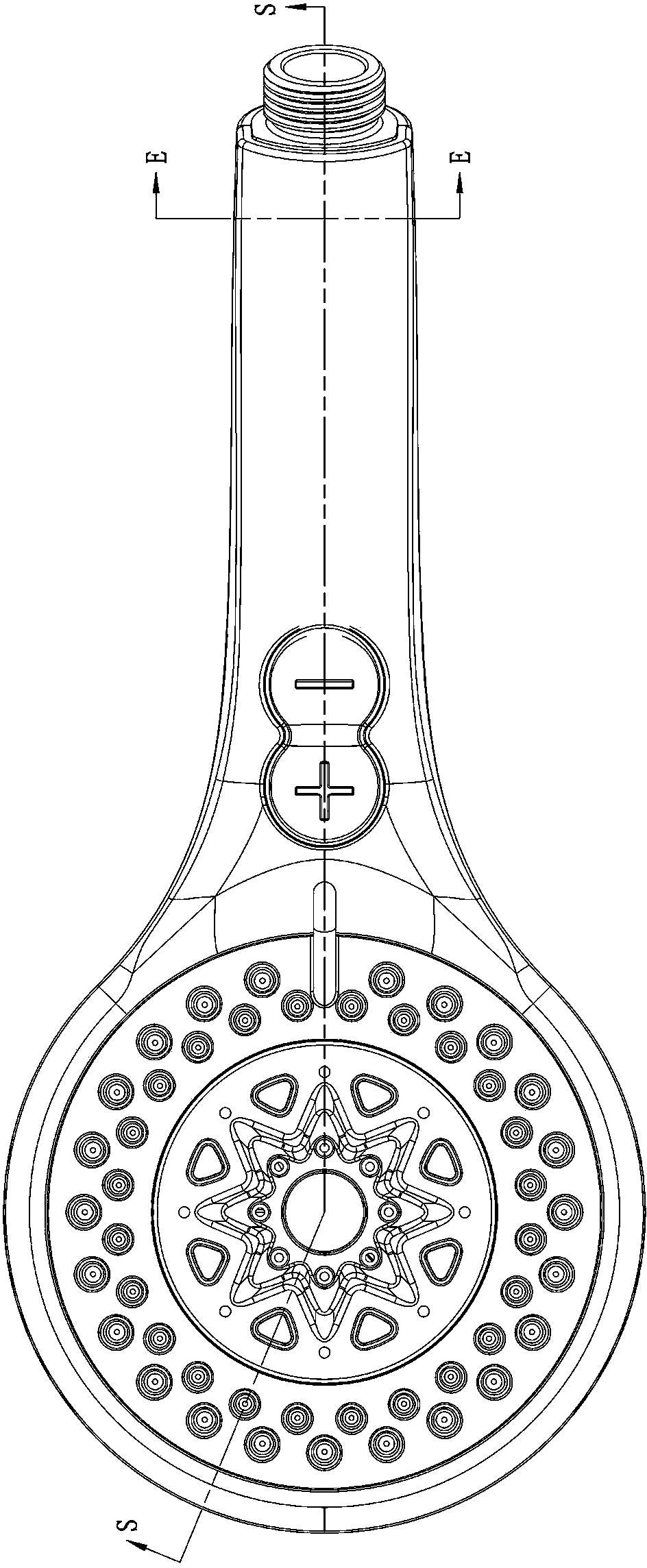

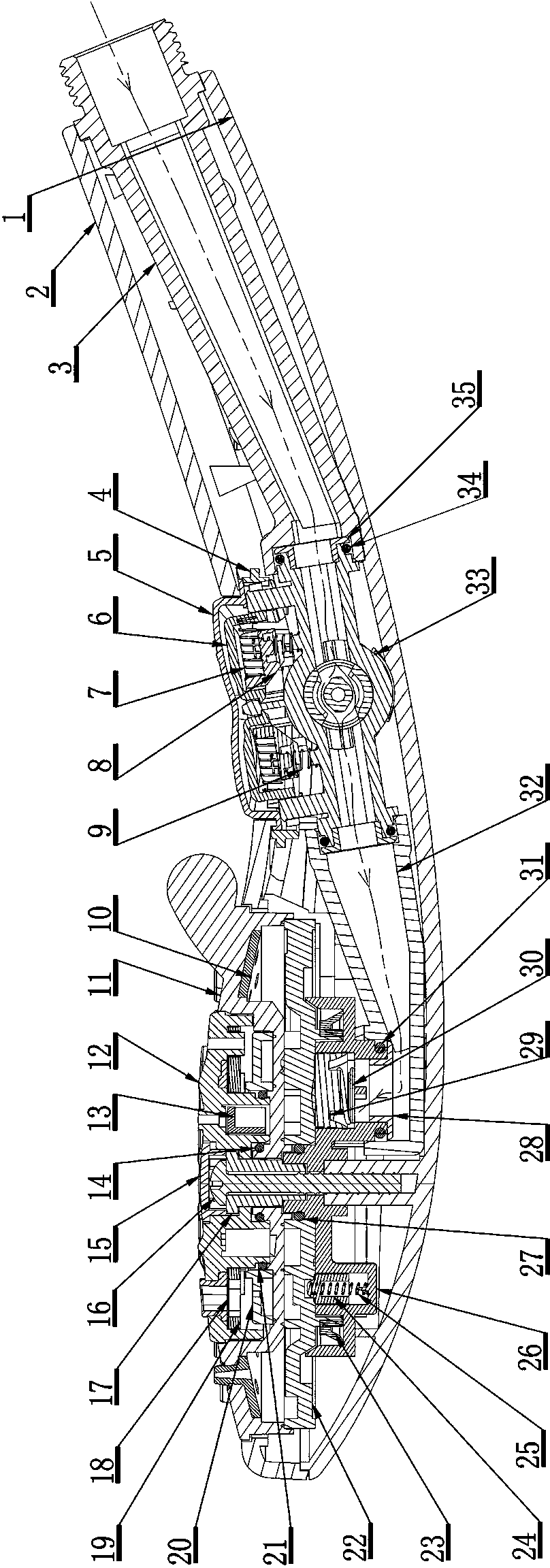

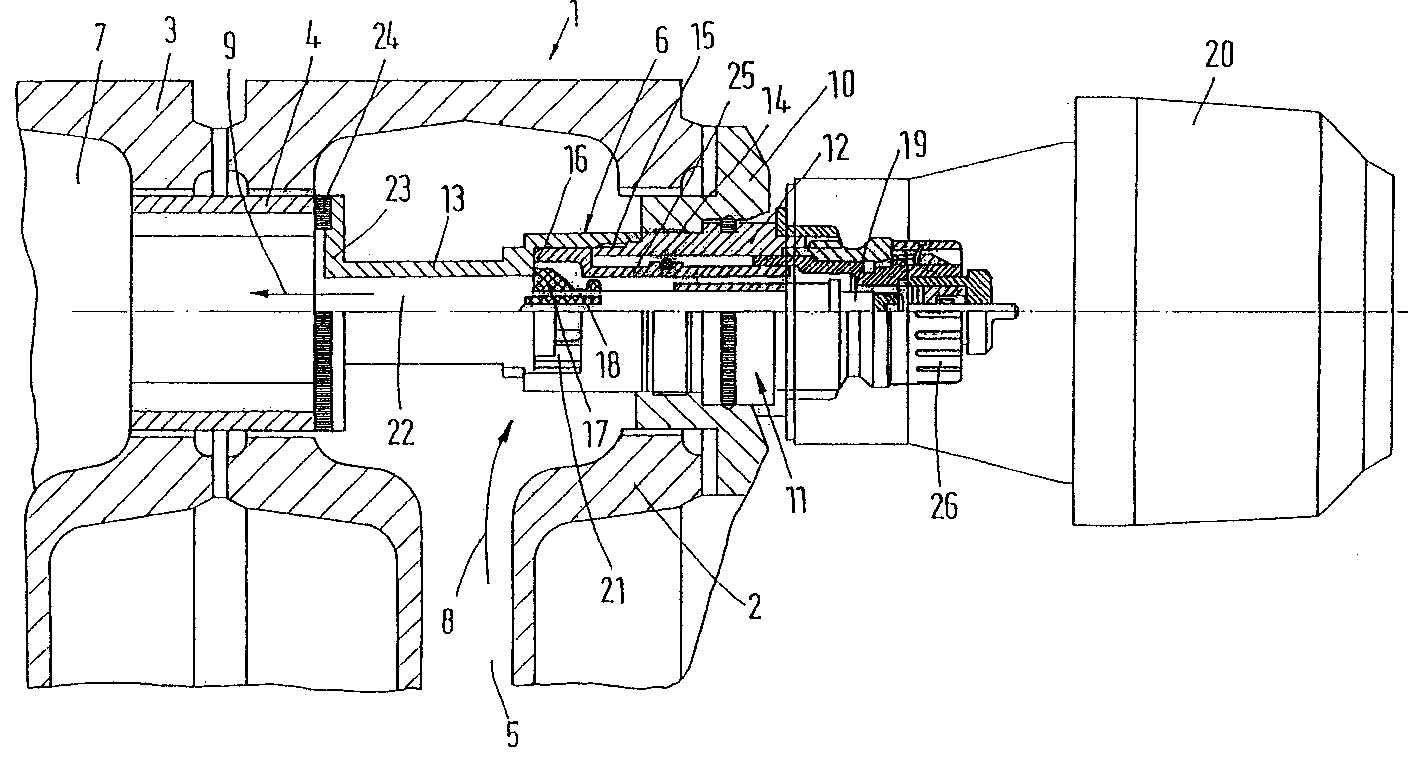

Button controlled flow shower head

The invention discloses a button controlled flow shower head. The shower head comprises three parts, namely a body fixing part, a surface cover water outlet part matched with a body, and a functional control part, wherein a V-shaped ring for sealing is arranged on each of a left control shaft and a right control shaft, the left control shaft and the right control shaft are arranged in a circular hole of a main pipe and fixedly connected by a screw sleeved with an O-shaped ring, and the left control shaft and the right control shaft can rotate in the circular hole; a spring is arranged on a button inner rack, and the button inner rack is arranged on buttons and can move forwards and backwards; the other spring is arranged at the bottom of the button inner rack, then the button inner rack is arranged on the main pipe, and the buttons drive the button inner rack to move vertically; a small cover plate and the O-shaped ring are respectively arranged on the end faces of the main pipe; and the functional control part is arranged between a water inlet pipe and a water entry pipe of the body fixing part, and the O-shaped ring is used for sealing the functional control part, the water inlet pipe and the water entry pipe. Through the shower head, grading regulation is realized in flow control; and the two buttons are used for controlling increase and reduction of the flow respectively, so that the shower head is definite and easy to operate. Under the control of the buttons, the internal regulating structure is tangential with the water flow direction, so the regulating force is small.

Owner:FUJIAN XIHE SANITARY WARE TECH

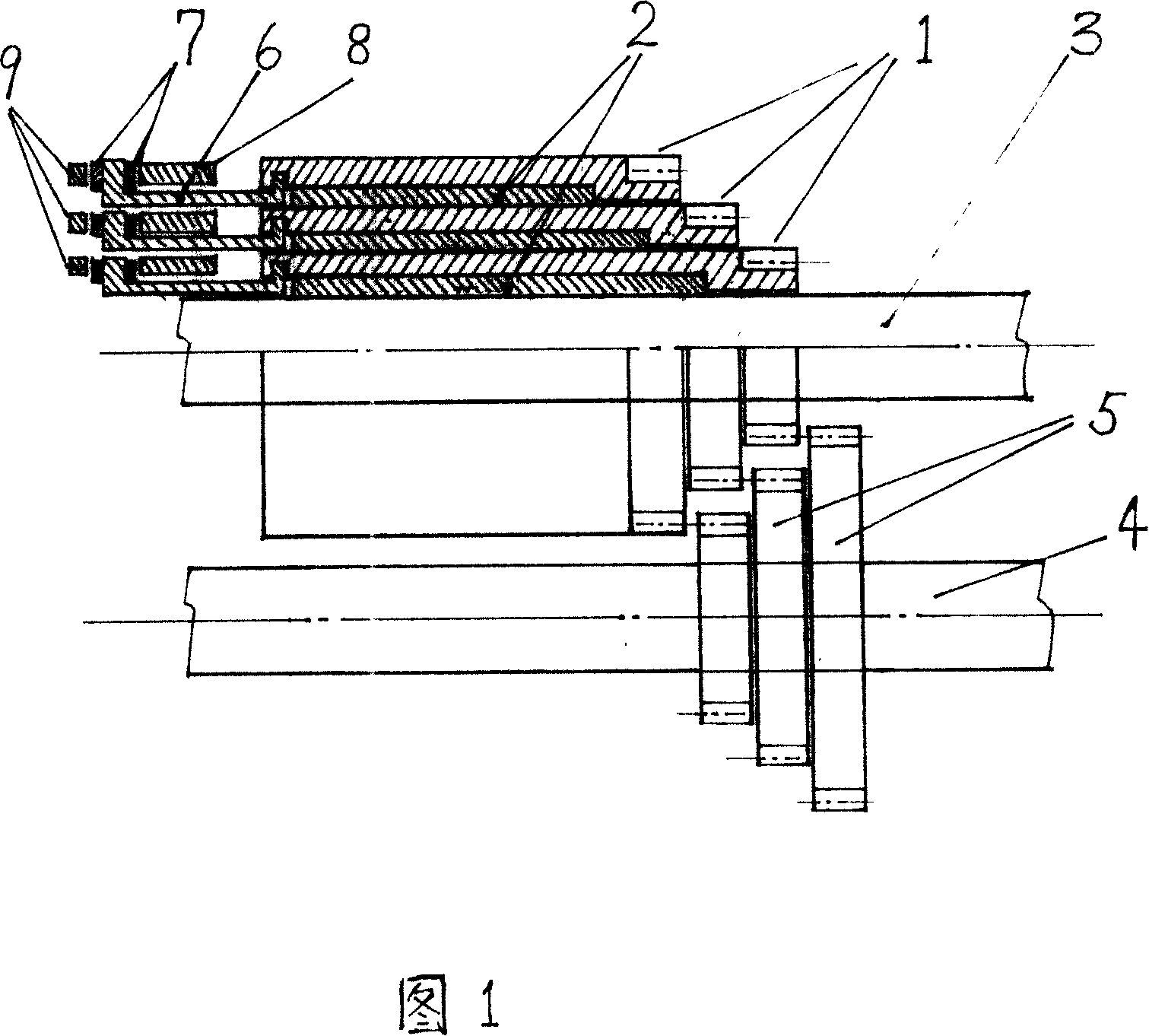

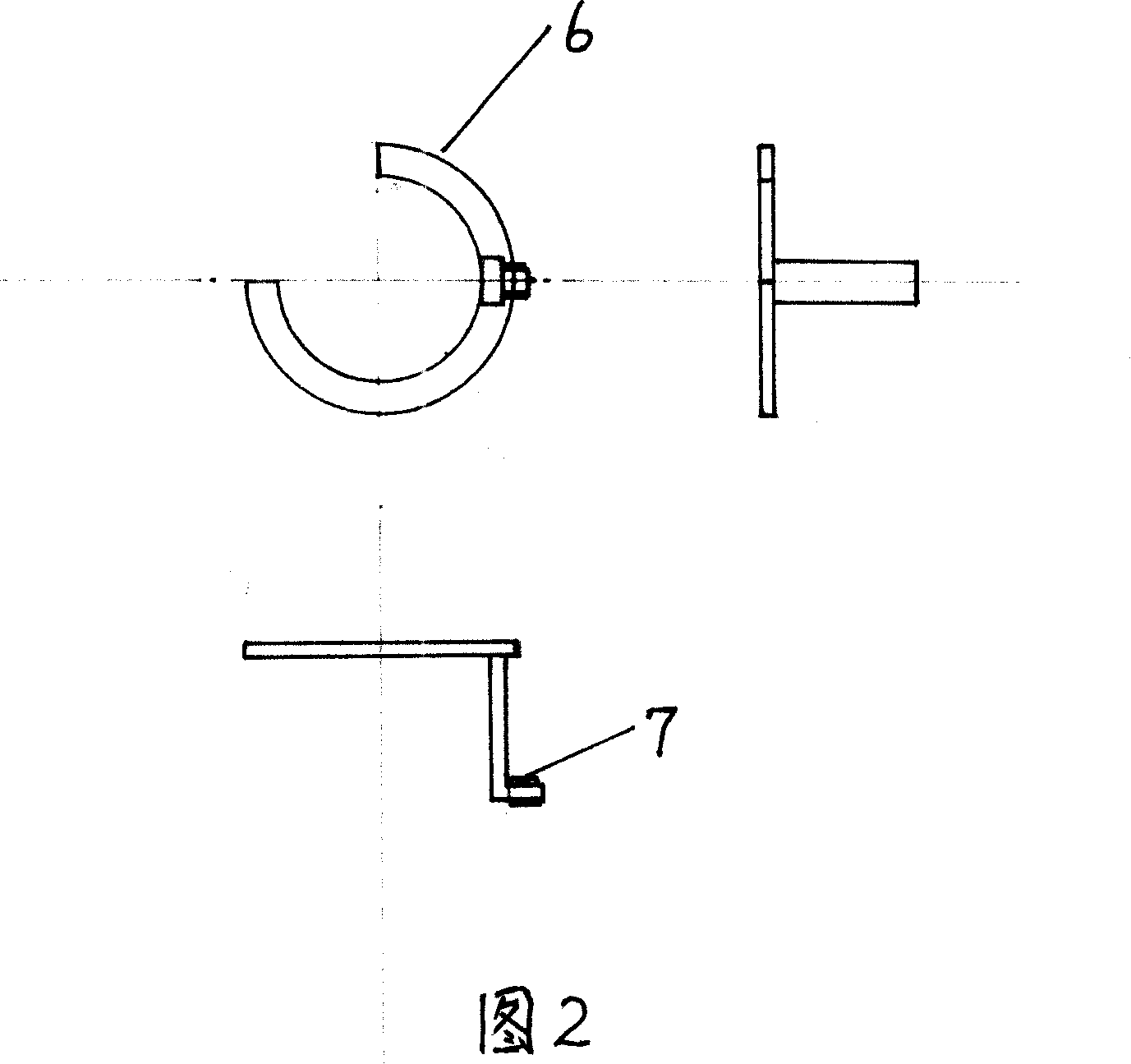

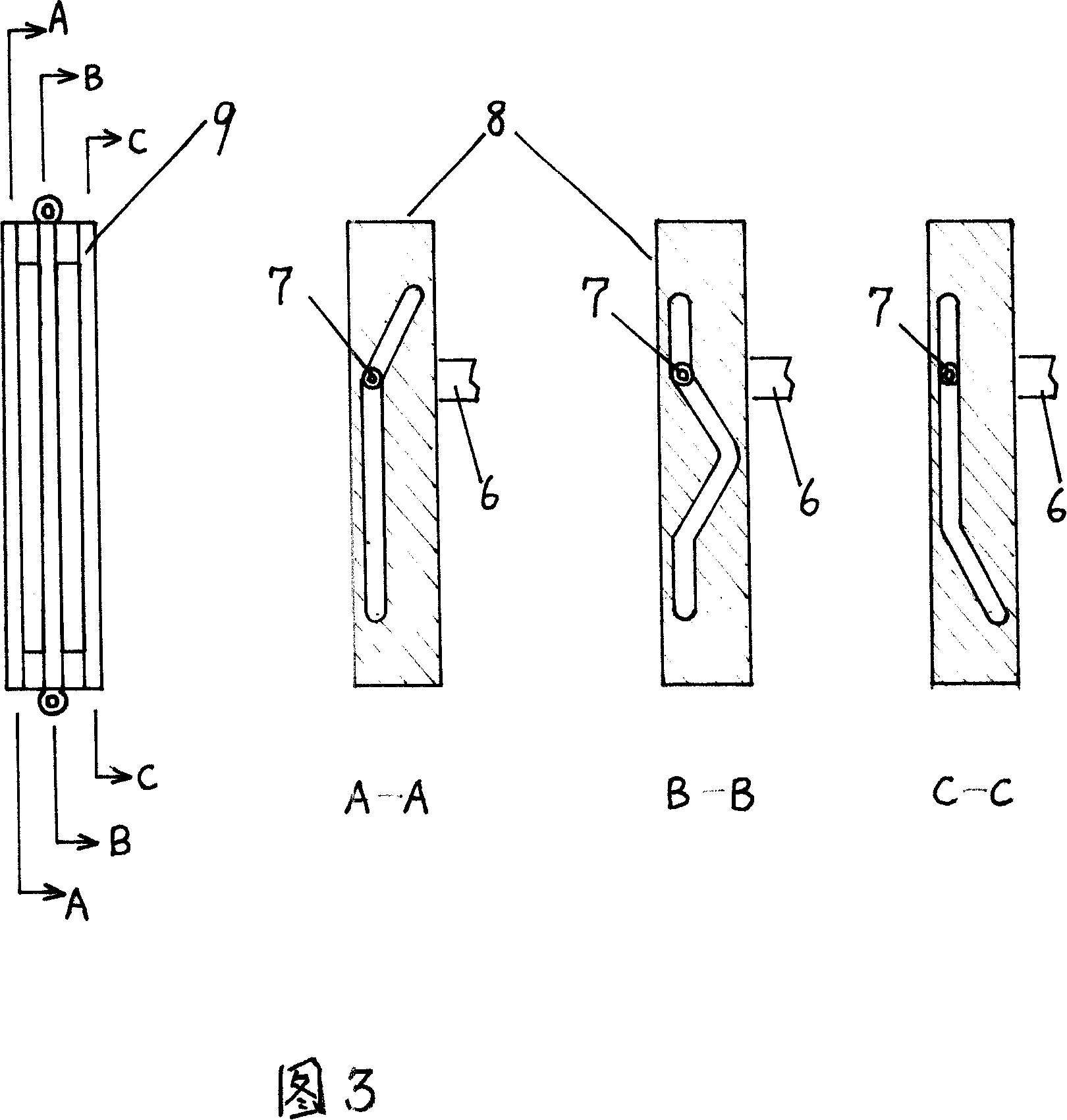

Housing gear speed variator and foldable bicycle

InactiveCN101130381AAccurate transmissionSmooth transmissionWheel based transmissionFoldable cyclesGear transmissionVariator

The invention relates to a sleeve-gear transmission and folding bicycle. There is a group of sleeve gears matched with a group of fixed gears. A part is driven to move or rotate by rope or bar to extrude a sleeve gear matched with a fixed gear. When the part moves again matched sleeve gear retracts. Another sleeve gear extrudes and is matched with another fixed gear to change speed. Moving is carried out continuously reciprocating speed increasing and speed decreasing can be realized. Speed-variable process is lightness and smooth. The transmission is set on the oblique bar of bicycle and is connected with gear, ratchet wheel and two straight driving wheels. The diameter of wheel is small than 10cm and the speed exceeds in prior bicycle. A pin is drawn out the main cubage of folded bicycle is only 8X15X99 cm. The transmission also can be used in electrical bicycle, motorcycle and other mechanism.

Owner:张明亮

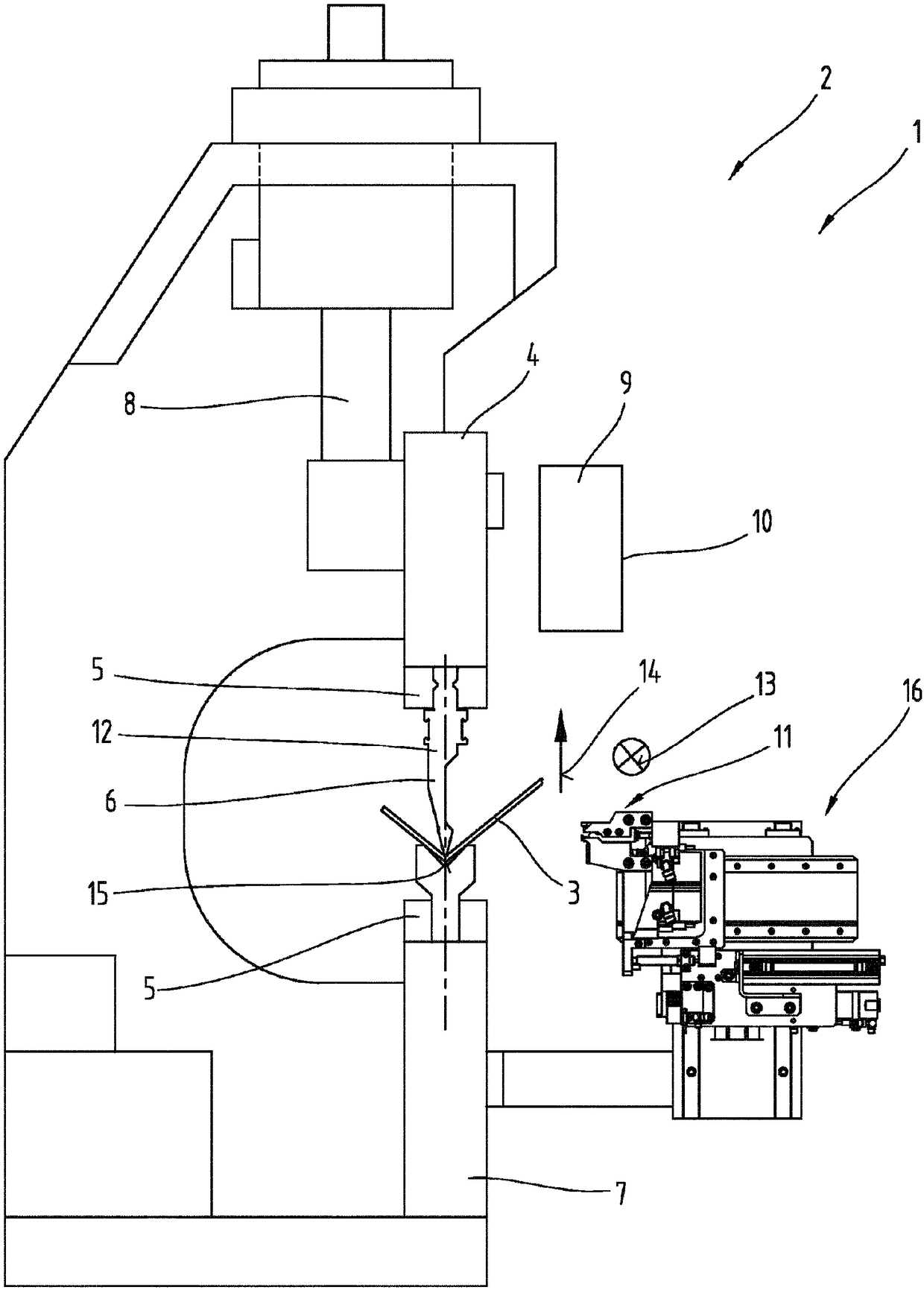

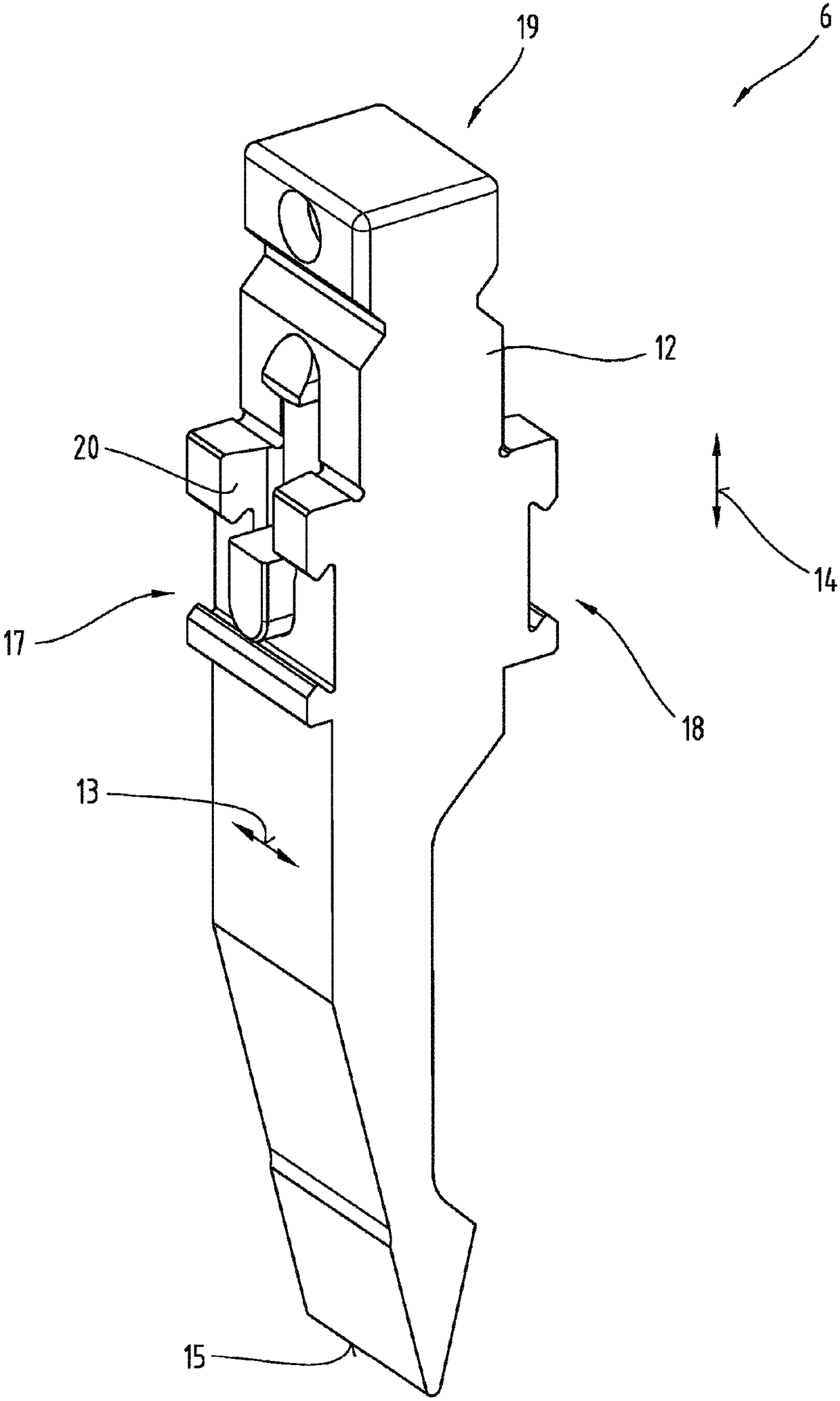

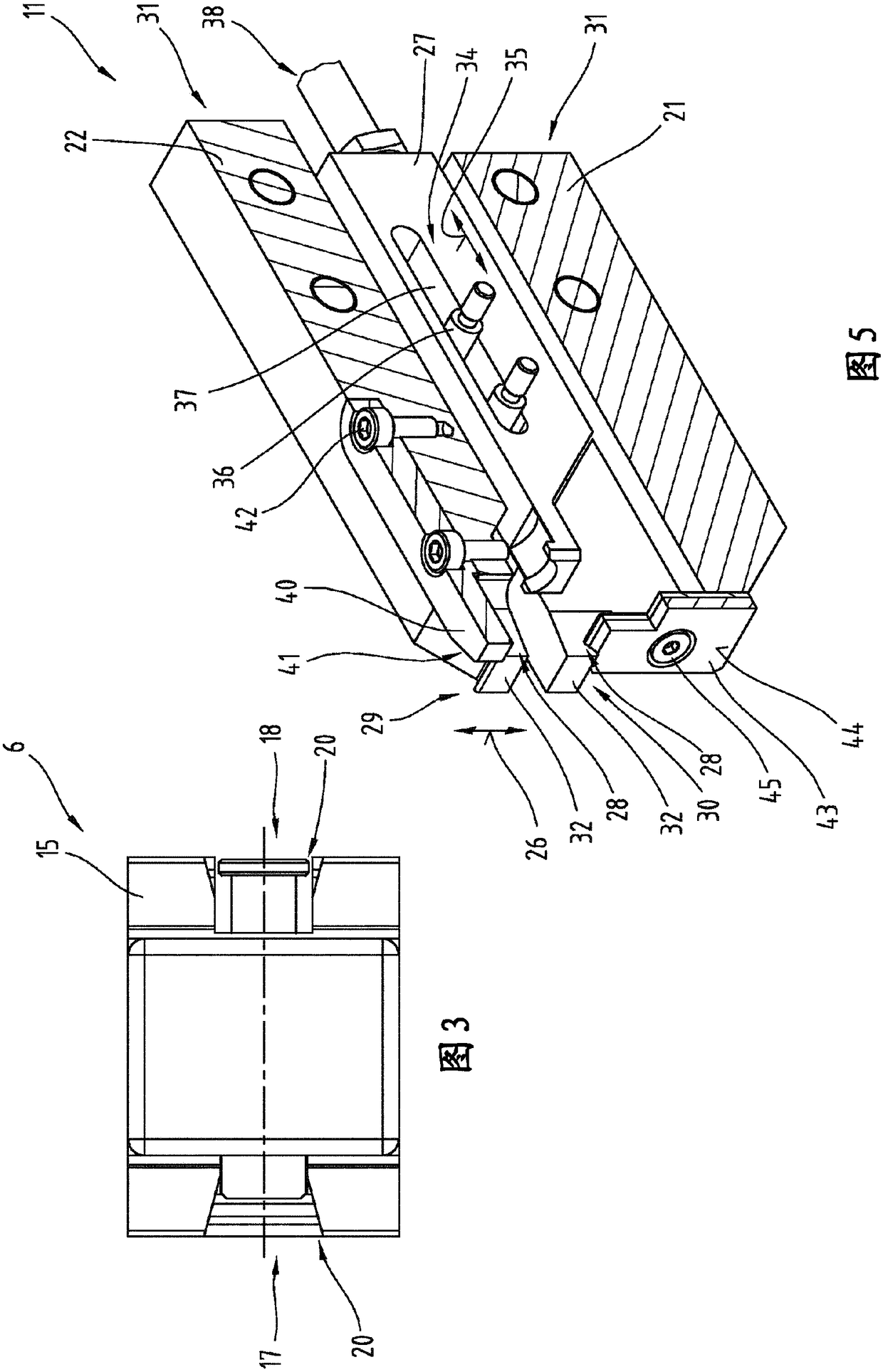

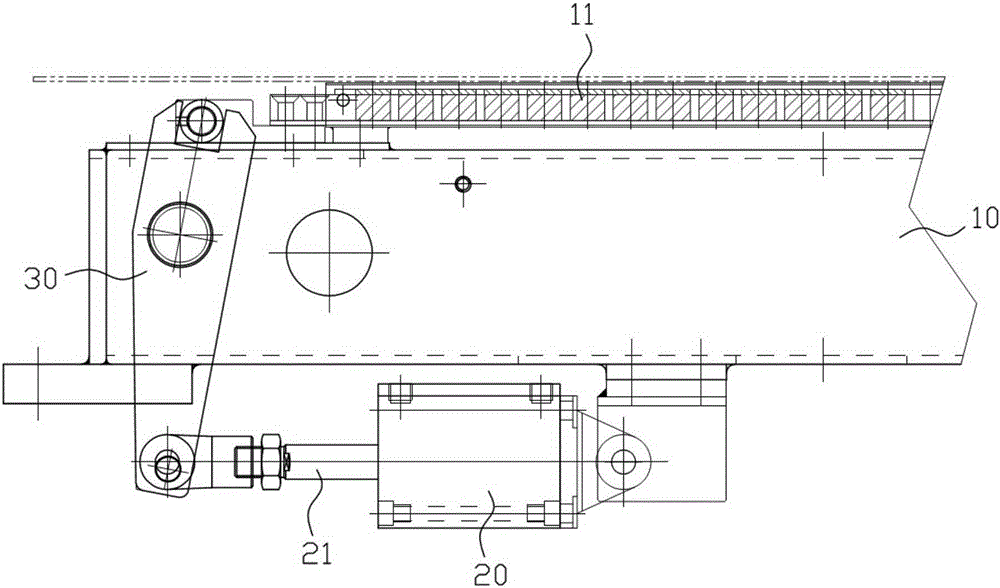

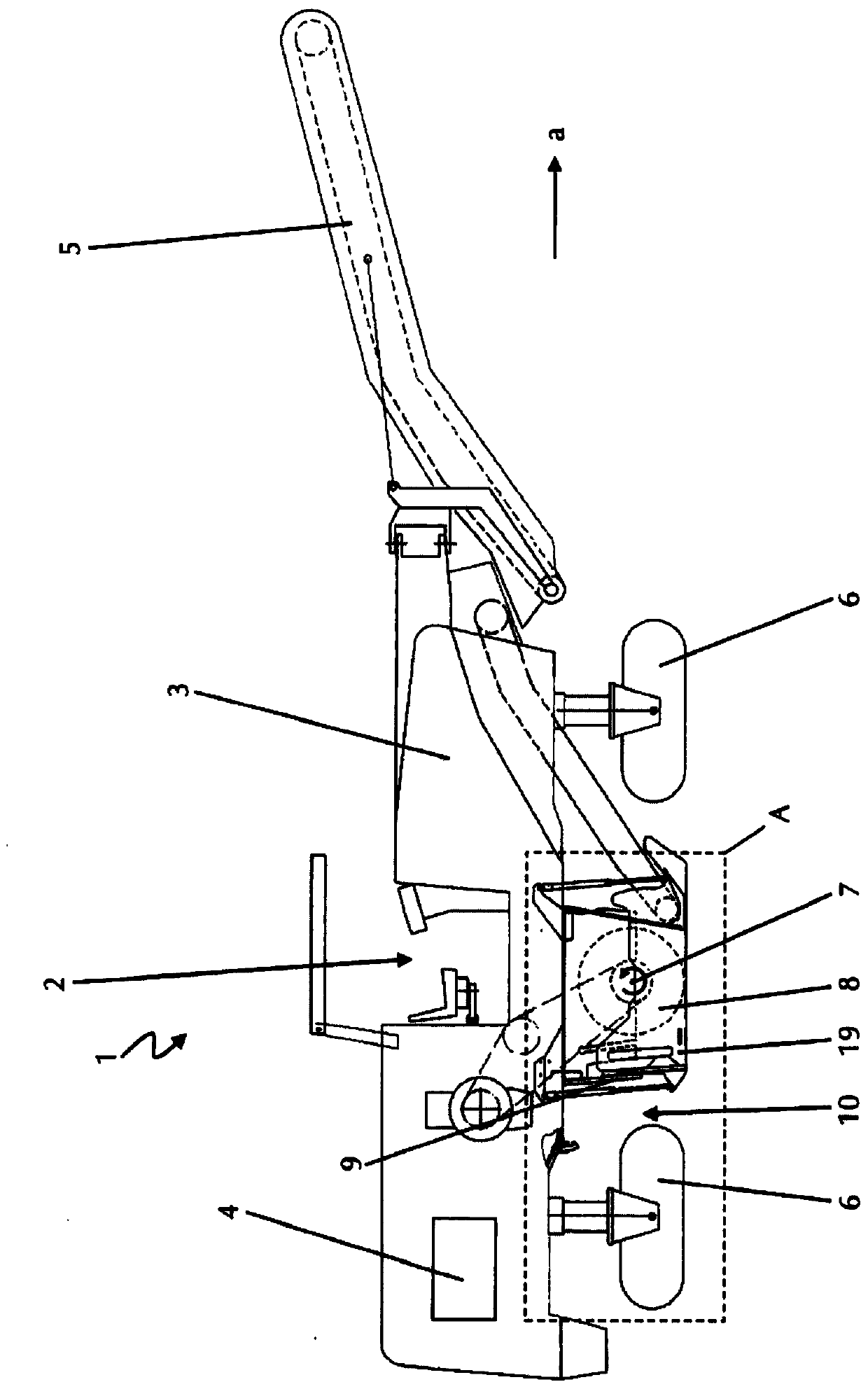

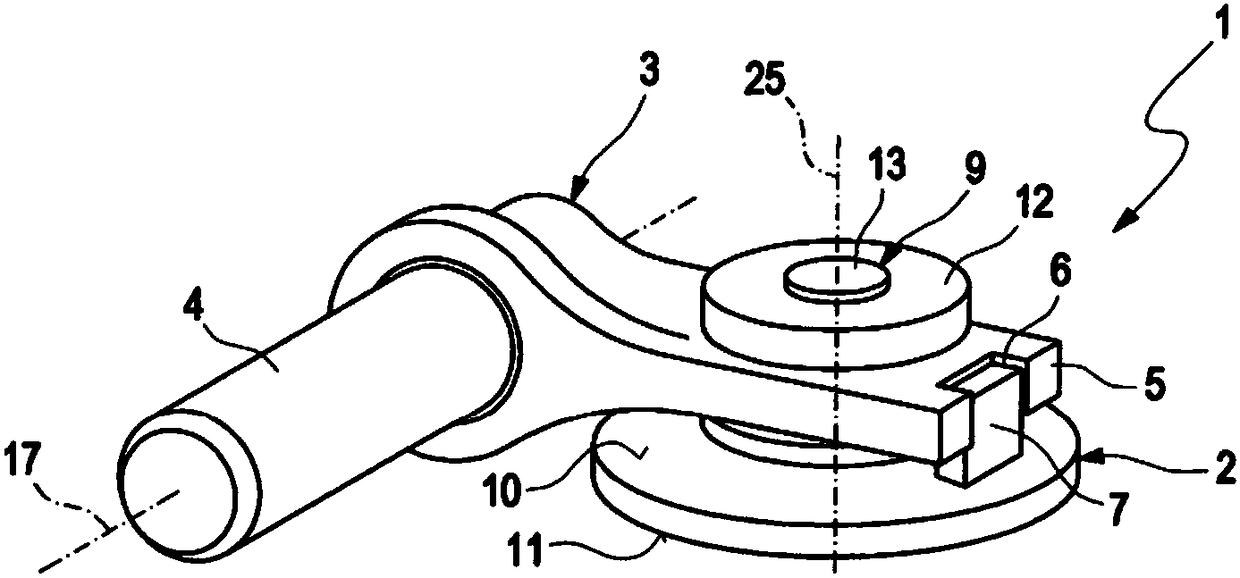

Gripper system for a bending press

ActiveCN108290194AKeep auxiliary timeKeep prep timeProgramme-controlled manipulatorShaping toolsClassical mechanicsCarriage

The invention relates to a gripper system (16) for a press brake (2), having a gripping device (11) for manipulating a bending tool (6). The gripping device (11) comprises a first gripping arm (21) and a second gripping arm (22) that is displaceable in the clamping direction (26) relative to the first gripping arm (21), said gripping arms (21) being configured to engage in a gripping groove (17, 18) in a bending tool (6) and to clamp the bending tool (6). The gripping device (11) is arranged on a carriage system (46), said carriage system (46) comprising a horizontal linear guide (47), by means of which the gripping device (11) is displaceable towards the gripping groove (17, 18) or away from the gripping groove (17, 18) in the longitudinal direction (35) of the gripping arms (21, 22).

Owner:TRUMPF MASCHEN AUSTRIA

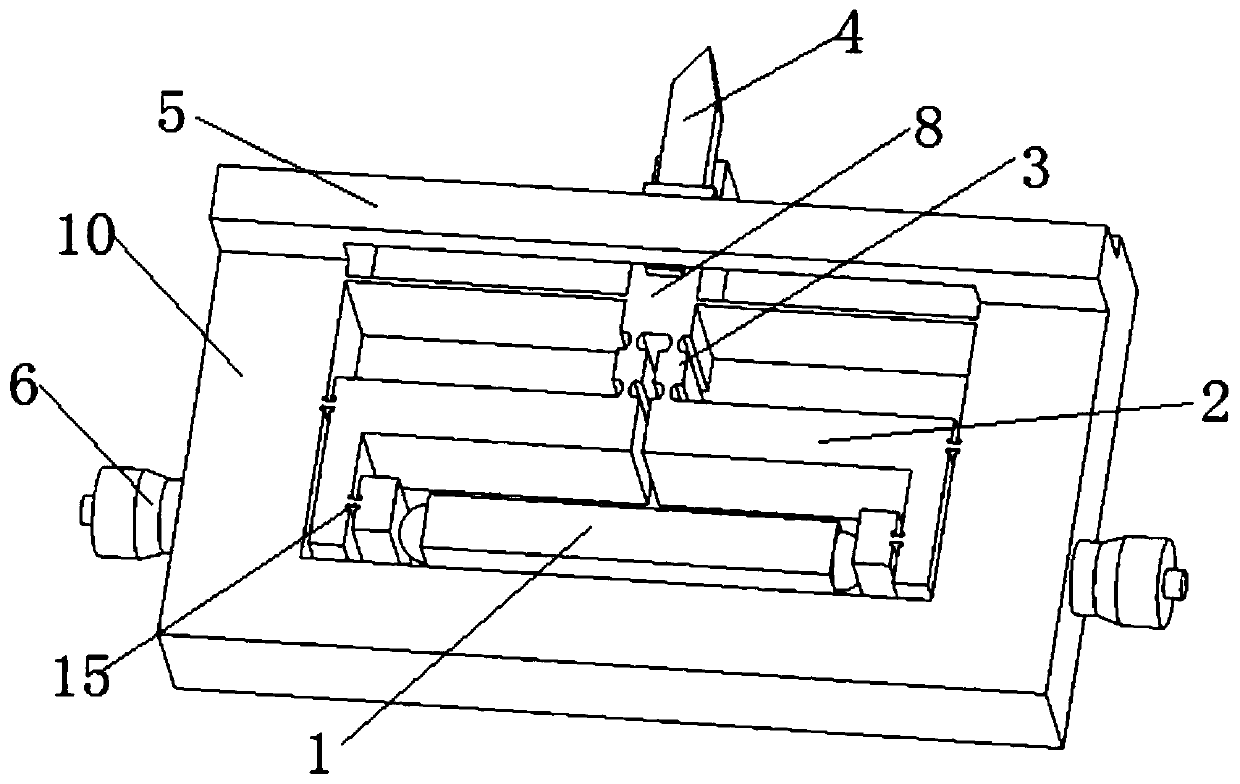

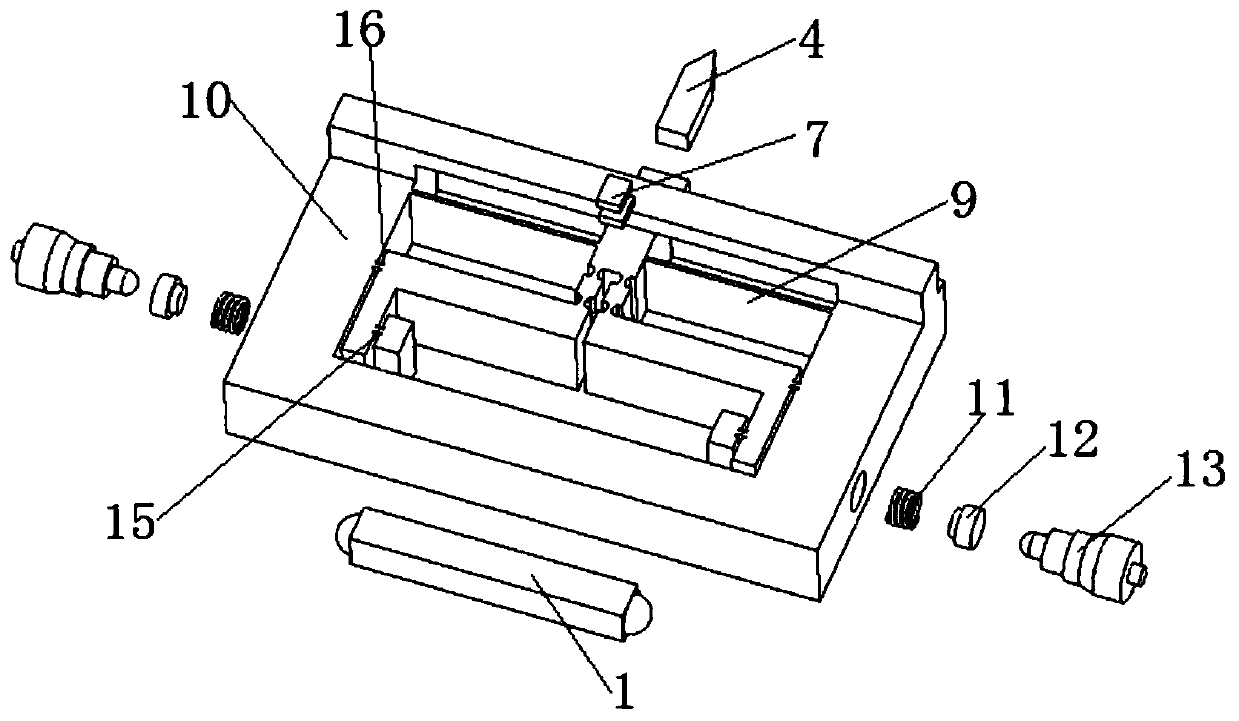

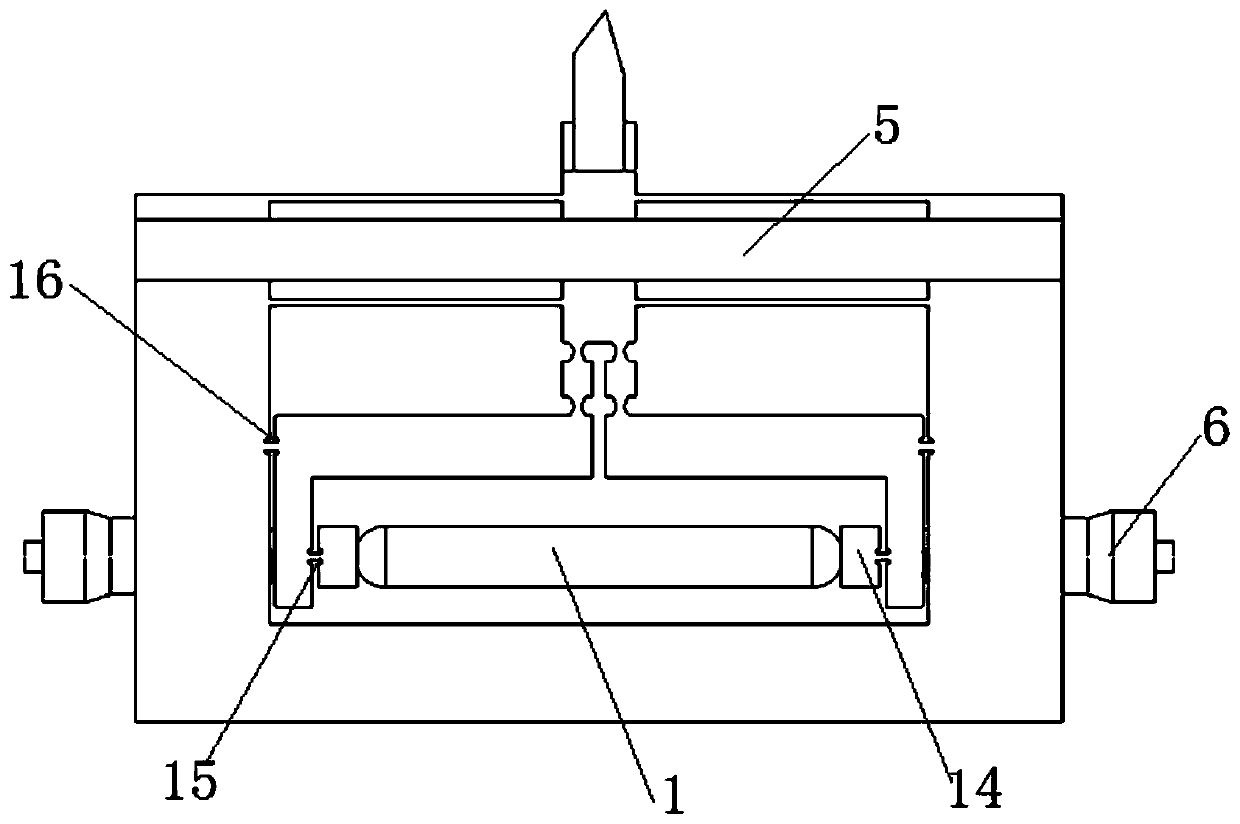

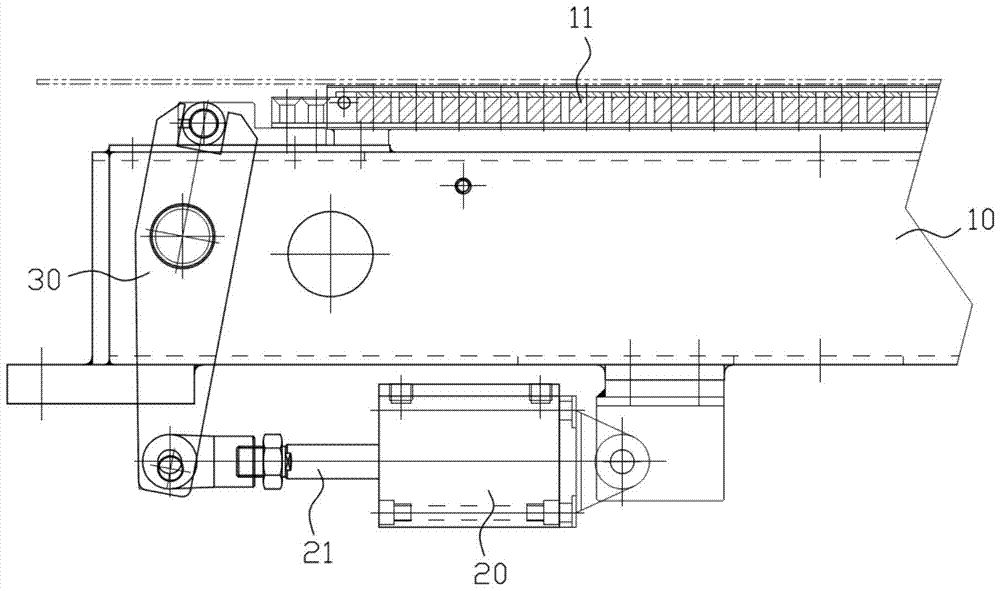

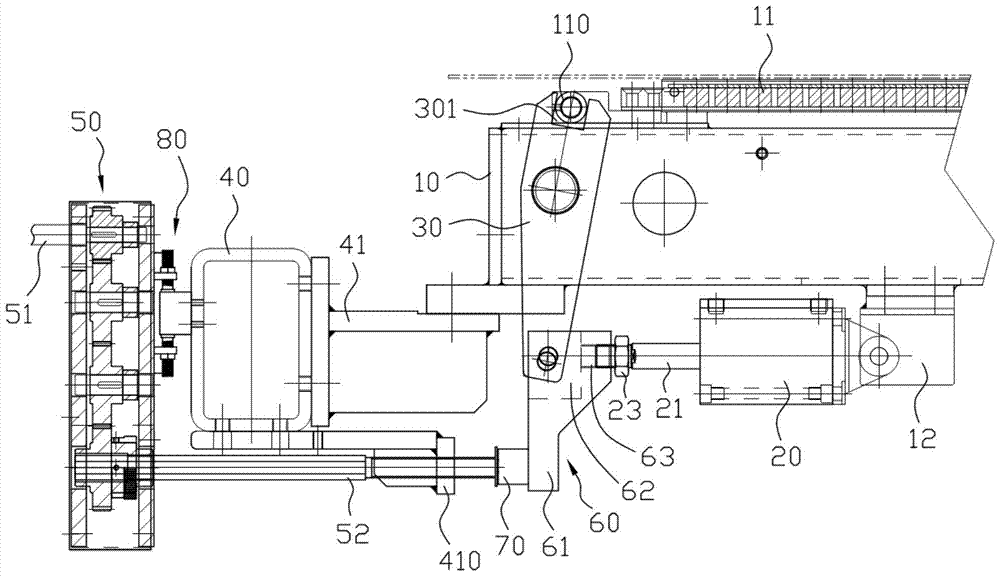

Device for regulating magnetic force of printing magnetic table through coordination of screw and air cylinder element

The invention discloses a device for regulating magnetic force of a printing magnetic table through coordination of a screw and an air cylinder element. The device comprises the air cylinder element mounted at the bottom of a magnetic table supporting body, and a rocker arm in pivoted connection with the magnetic table supporting body. The bottom end of the rocker arm is connected with a center shaft of the air cylinder element through a double-lug ring, and the top end of the rocker arm is connected with the magnetic table. The device for regulating the magnetic force further comprises a gear set mounted on the outer side wall of a side beam, a transmission rod connected with a driving gear in the gear set, and the regulating screw connected with a driven gear in the gear set. One end of the regulating screw is in threaded connection with the interior of a threaded hole of the driven gear, and the other end of the regulating screw is connected with the bottom end of the double-lug ring through an abrasion preventing device. Through the technical scheme, the regulating screw can be driven by the gear set to move backward or forward only by applying small external regulating force to the transmission rod, the abrasion preventing device can transmit power to the rocker arm under the circumstance that contact between the regulating screw and the double-lug ring is avoided, moreover, the center shaft is stretched out and drawn back, and the magnitude of the magnetic force of the magnetic table is regulated accurately and effectively.

Owner:HUZHOU HUISHENG MACHINERY

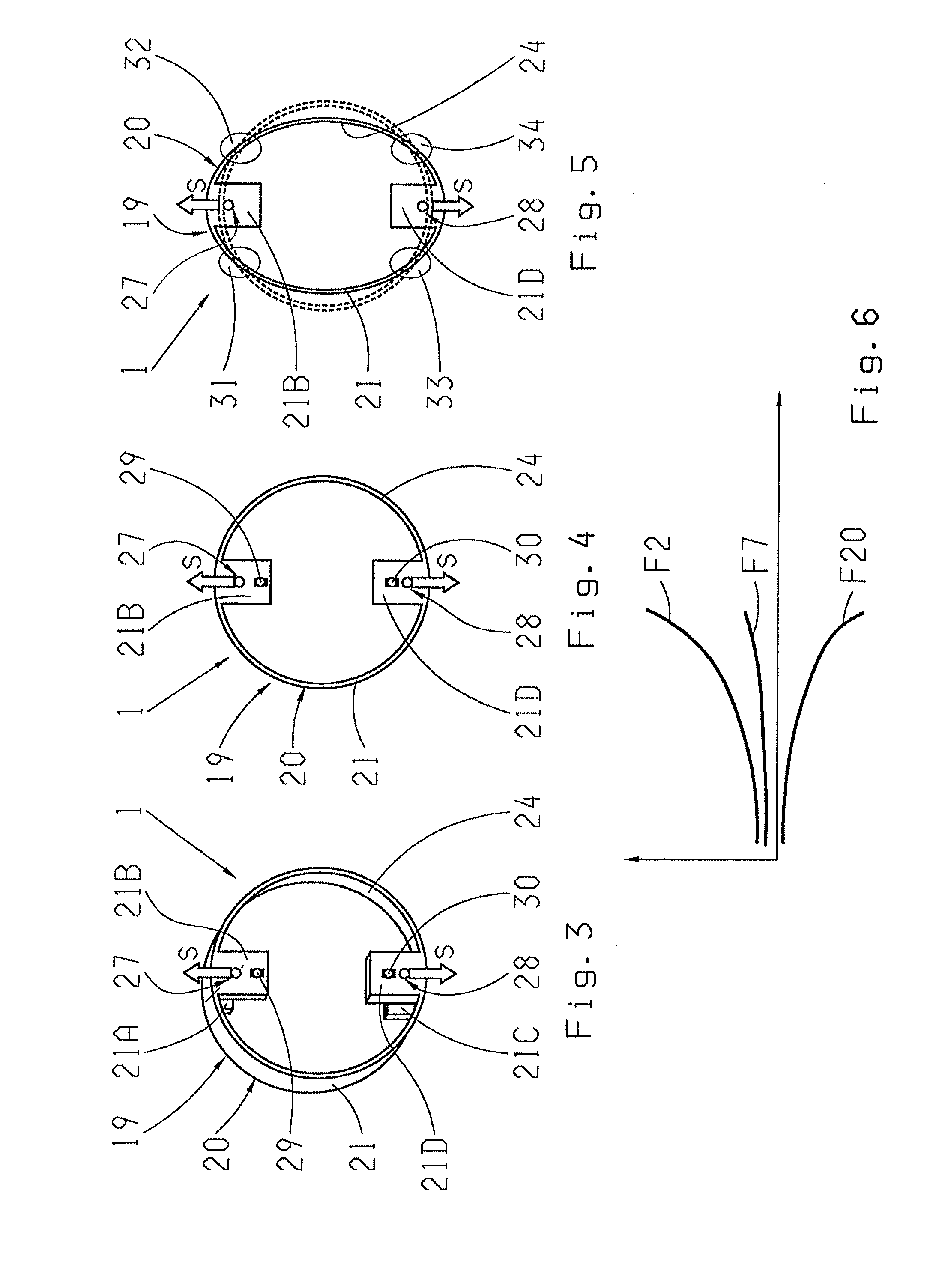

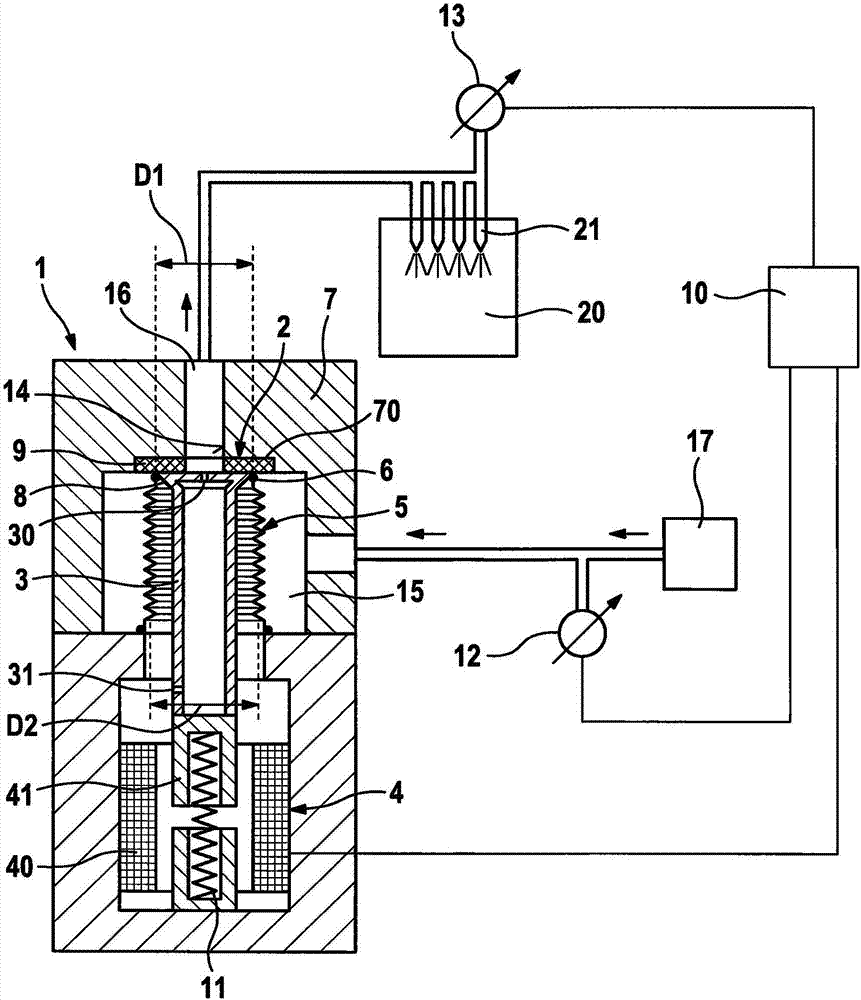

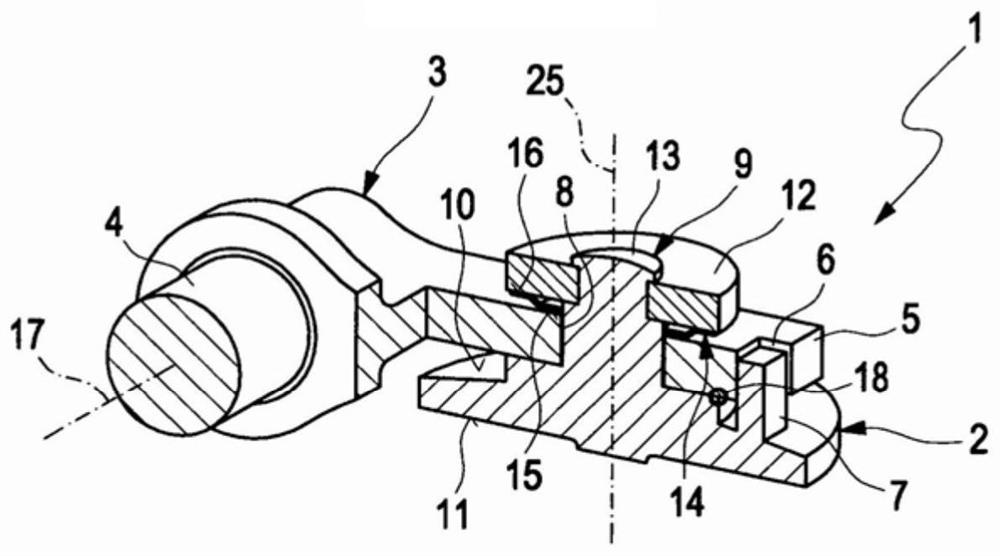

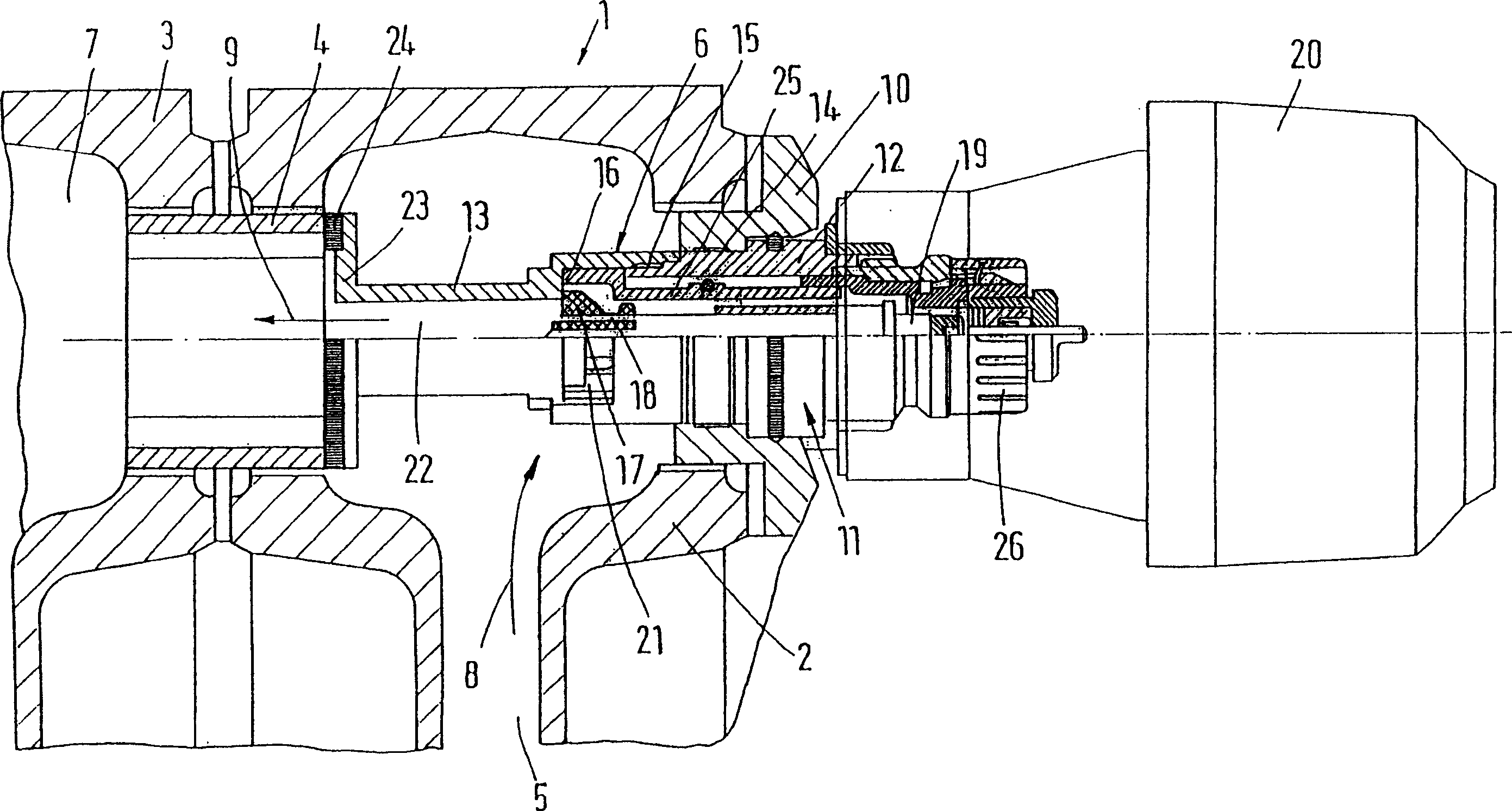

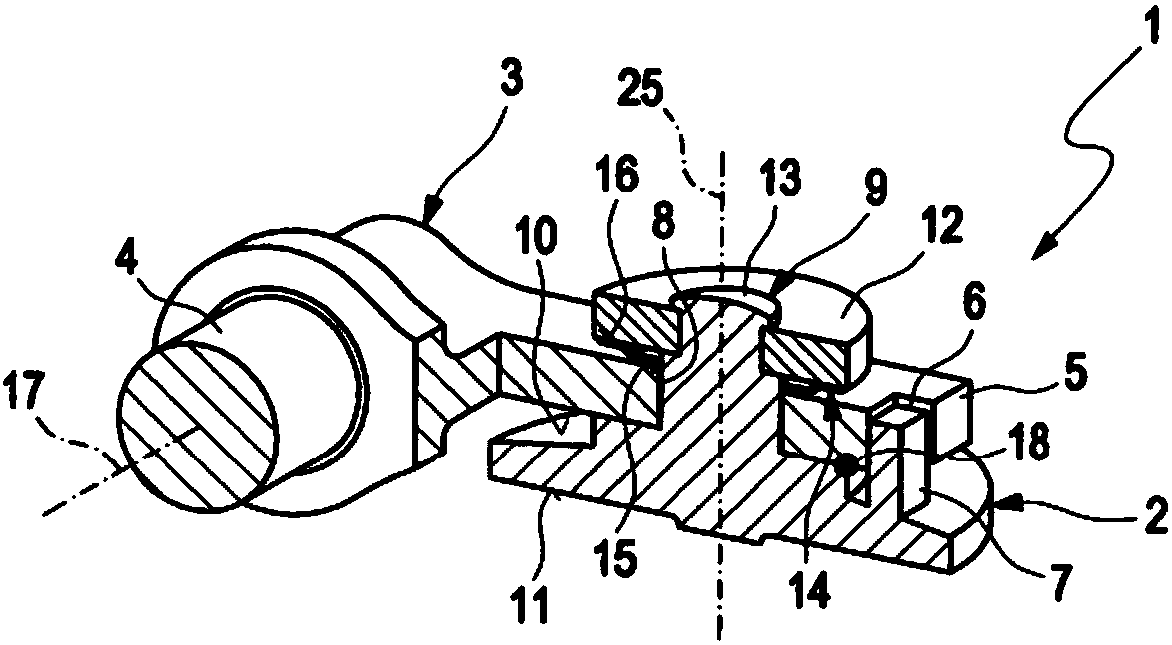

Device for changing an operational status of a shifting element with two shifting element halves

InactiveUS20120255828A1Easy to operateLittle controlMagnetically actuated clutchesGearing controlStress conditionsSpring force

A mechanism for changing the operating condition of a shifting element having two shifting element halves, which can either be functionally connected to connect two components or disengaged to break the connection between the components. The mechanism includes a drive machine and a drive converter unit in the area of which rotary drive motion of the drive machine can be converted into a translational actuation movement of the shifting element. A spring device is associated with the drive converter unit, whose spring force assists with actuating the shifting element in the engaging direction. The spring device includes an approximately circular flat spring element which, in at least one area of the drive converter unit, is in contact with at least one cam, whose stress condition varies as a function of an operating condition of the drive converter unit and is designed to be rotationally fixed.

Owner:ZF FRIEDRICHSHAFEN AG

Button control flow shower

ActiveCN102688816BClear and simple operationSmall regulationSpray nozzlesControl flowControl engineering

Owner:FUJIAN XIHE SANITARY WARE TECHNOLOGY CO LTD

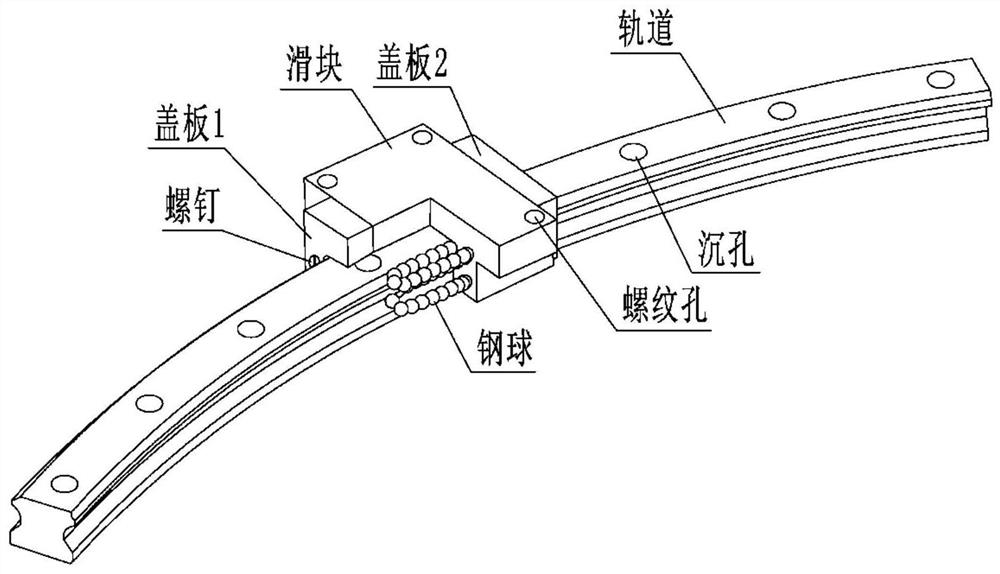

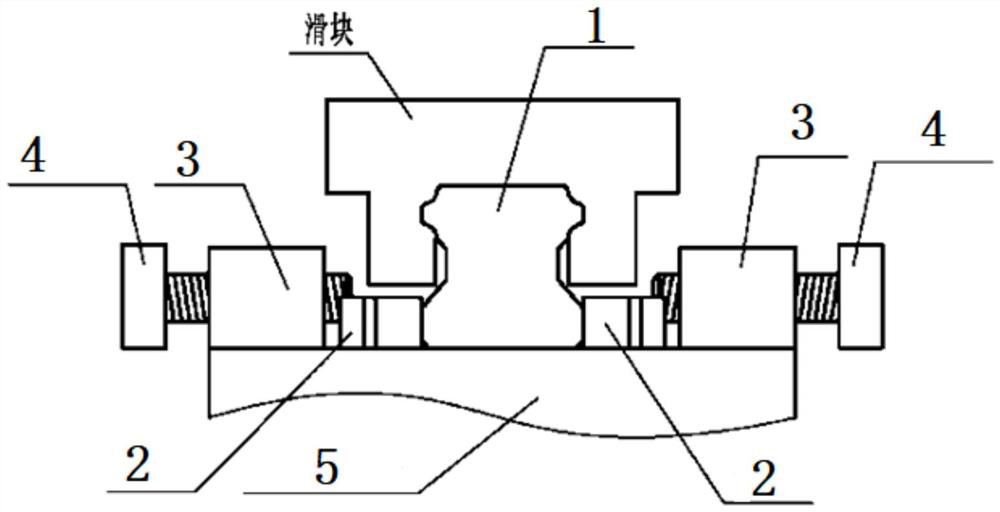

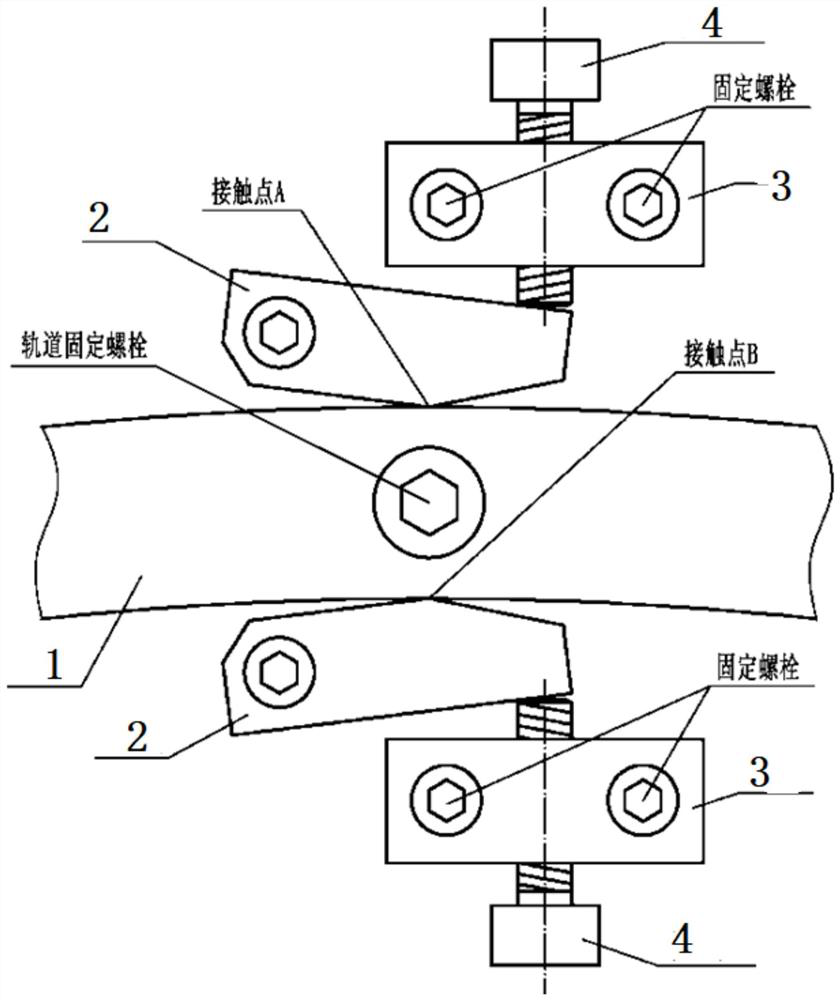

Radial positioning mechanism of arc rolling guide rail

ActiveCN113187813AImprove radial positioning stiffnessHigh strengthLinear bearingsClassical mechanicsJackscrew

The invention discloses a radial positioning mechanism of an arc rolling guide rail. The radial positioning mechanism comprises a plurality of adjusting blocks symmetrically installed on the two sides of a rail, fixing blocks are arranged on the sides, away from the rail, of the adjusting blocks, fine adjustment screws are installed on the fixing blocks, and the fine adjustment screws penetrate through the fixing blocks and then abut against the sides, away from the rail, of the adjusting blocks. The adjusting blocks and the fixing blocks are all fixed to a rail mounting base, and the sides, close to the rail, of the adjusting blocks are in linear contact with the side face of the rail. According to the radial positioning mechanism of the arc rolling guide rail, the problems that in the prior art, a rail jackscrew used for radial positioning and adjusting is small in diameter, the radial positioning rigidity and strength are low, and under the action of high radial loads, the radial deformation of a rail is large, and the rotation precision is affected are solved.

Owner:XIAN UNIV OF TECH

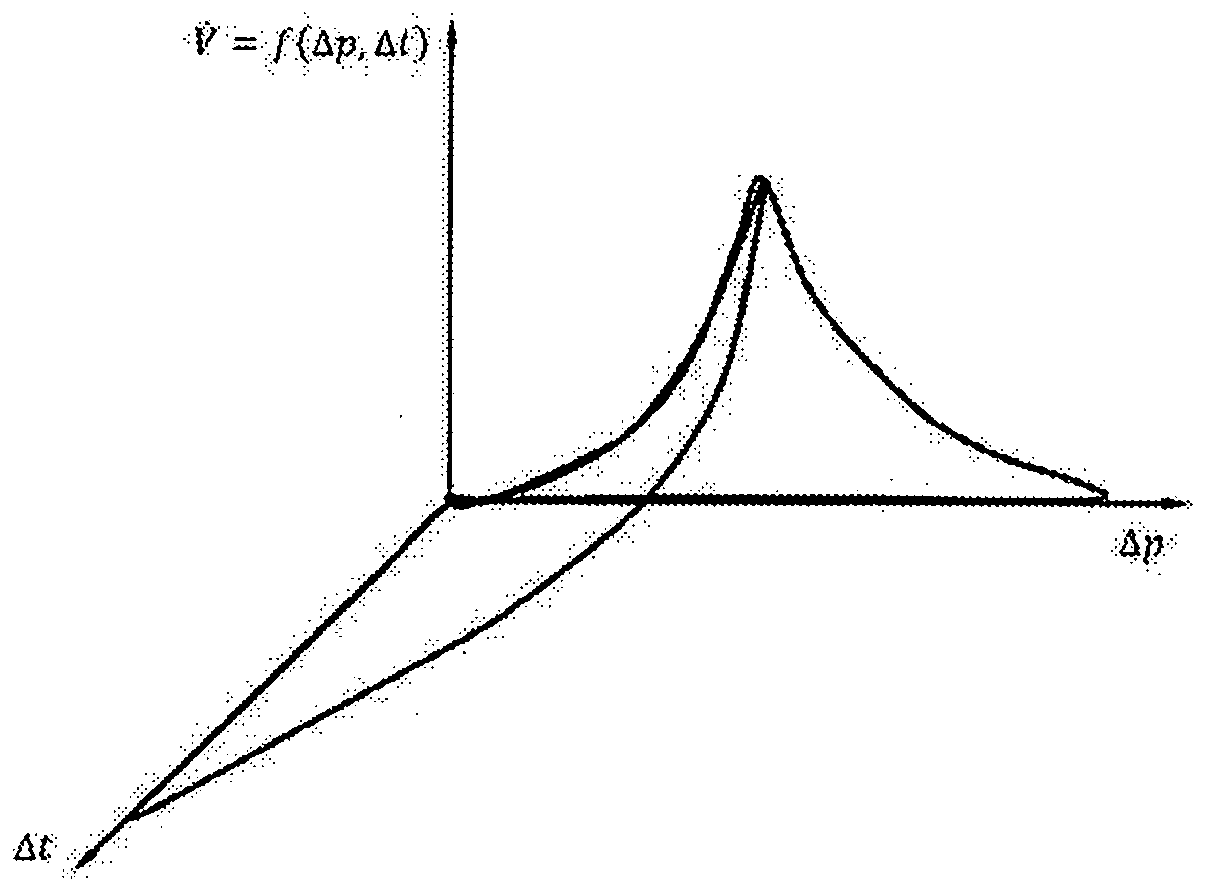

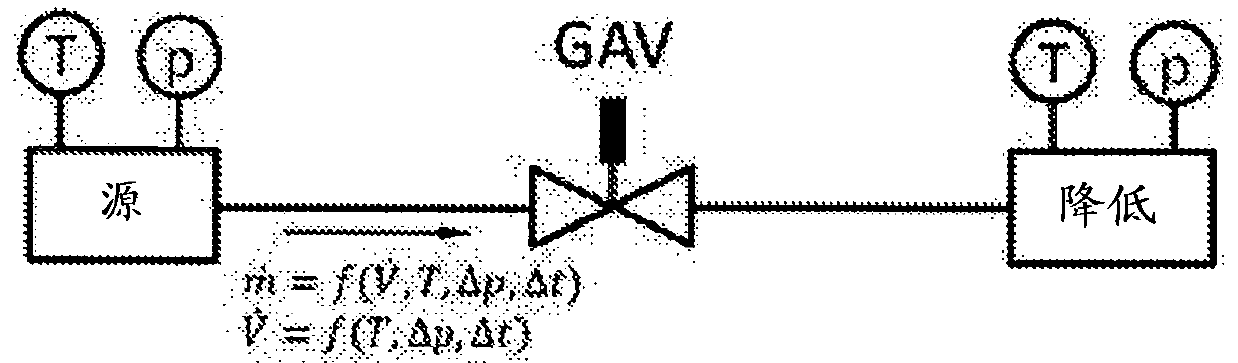

Gas feed method for a gas engine or dual-fuel engine, and gas supply apparatus for same

ActiveCN109715921AAdjust air pressureNo inertia effectElectrical controlInternal combustion piston enginesProcess engineeringAtmospheric pressure

Owner:汉堡-哈尔堡工业大学

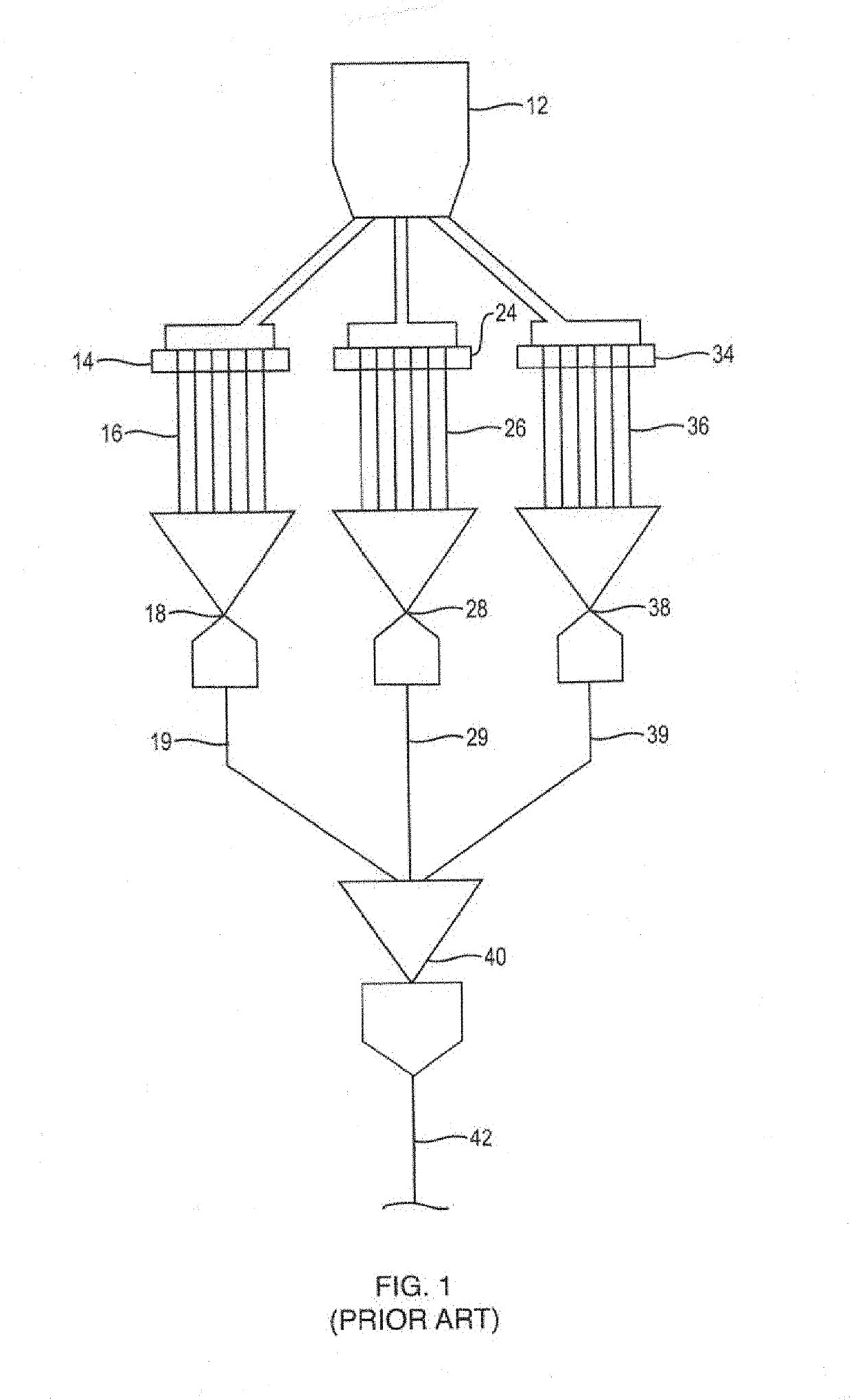

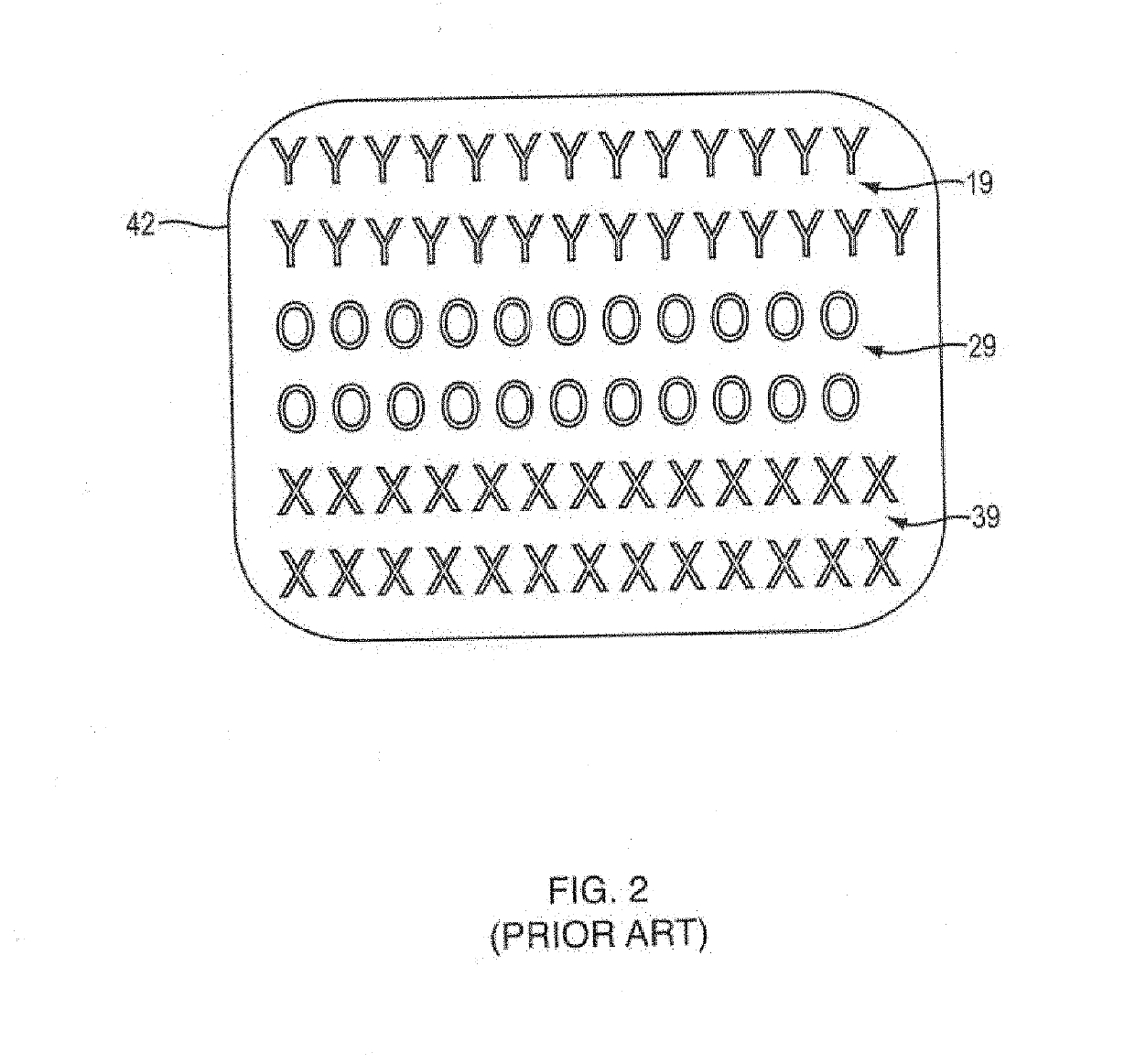

Hybrid yarns formed with fibers having rounded tips and method of making the same

InactiveUS20190194827A1Not deteriorate performanceLight weightFilament/thread formingYarnYarnEngineering

A hybrid yarn and a fabric including the hybrid yarn are provided. The hybrid yarn is formed of a plurality of fibers of a plurality of different fiber compositions. The fibers of different configurations are homogenized and intimate with one another throughout the yarn. The yarn may be formed using fibers made of the same material or a plurality of different materials. The different fiber compositions may include fibers of three or more different cross sections, fibers made of different materials or a combination of the two. Fibers having tips or ends are made so that the tips are rounded rather than squared to improve the manufacture and quality of the yarn. The materials may be synthetic and / or natural materials. Fabrics made with the hybrid yarn will have selectable functional features and also be of lighter weight than previously possible. Hybrid spinnerets may be used to produce hybrid yarns with three or more different fiber cross sections wherein spinneret portals that have tips are made with the tips rounded.

Owner:COOLCORE

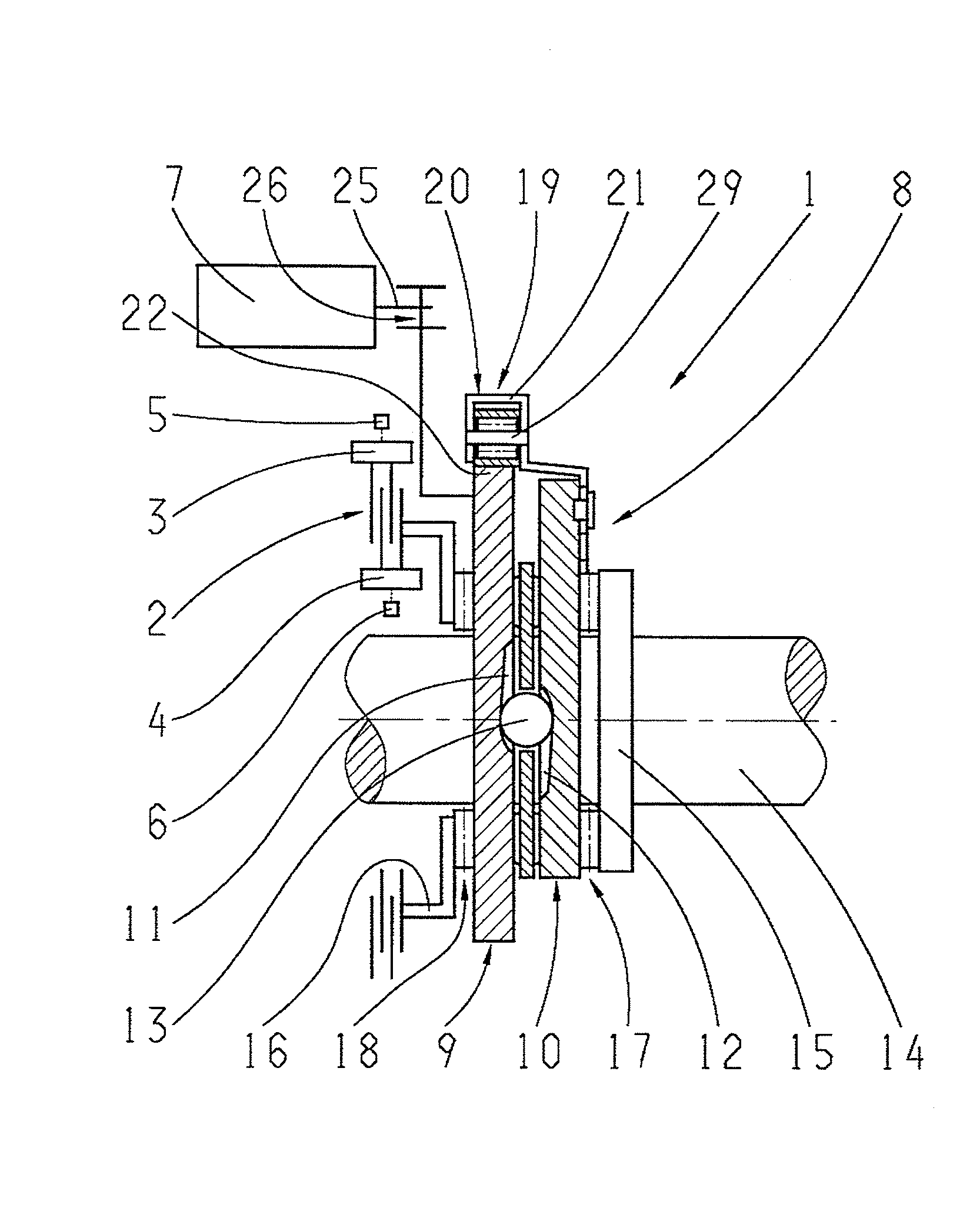

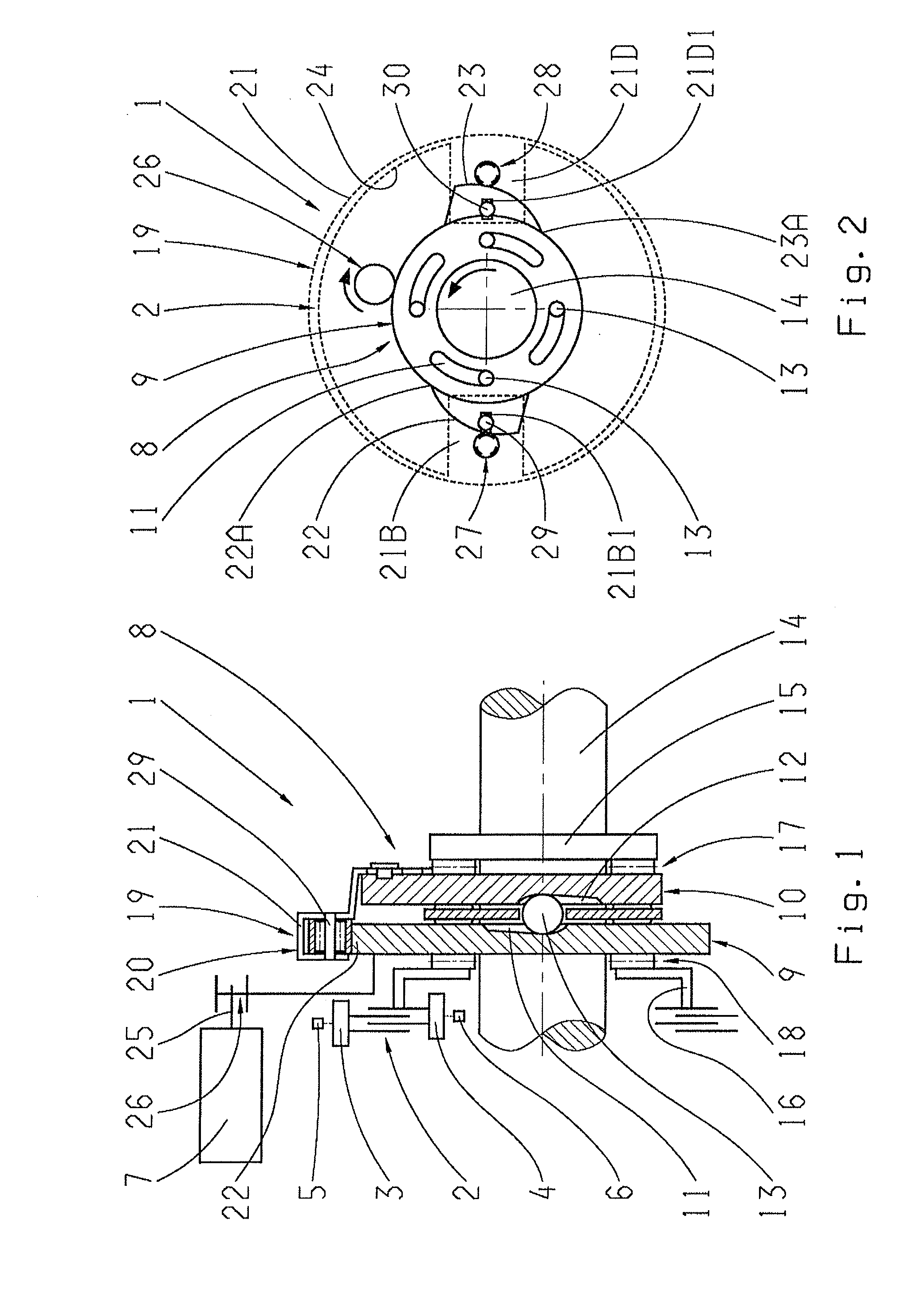

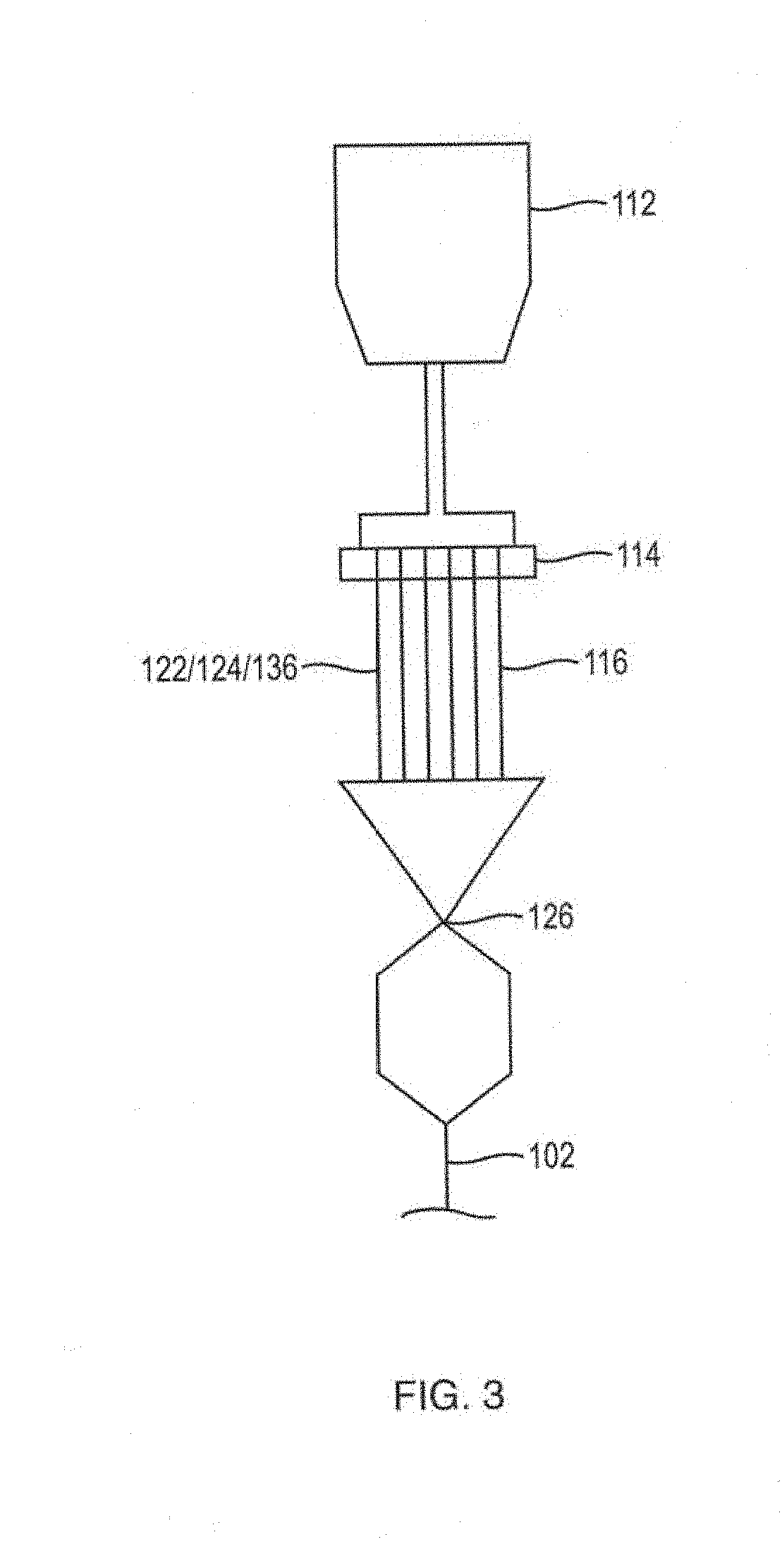

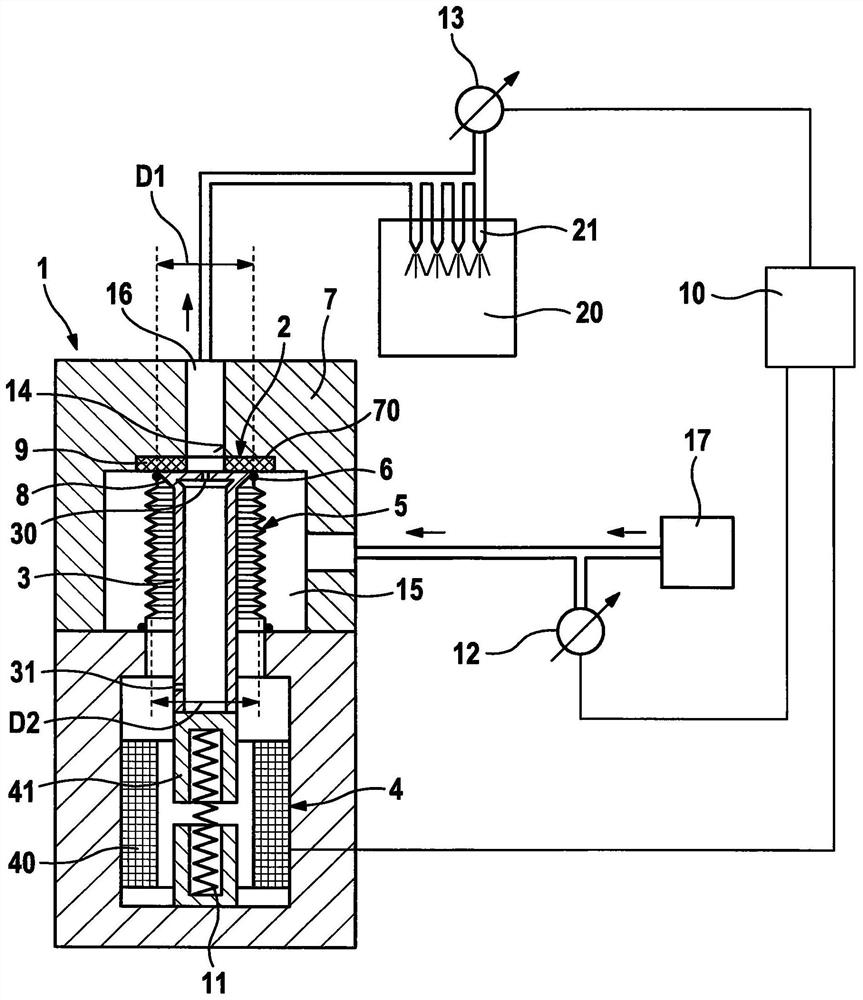

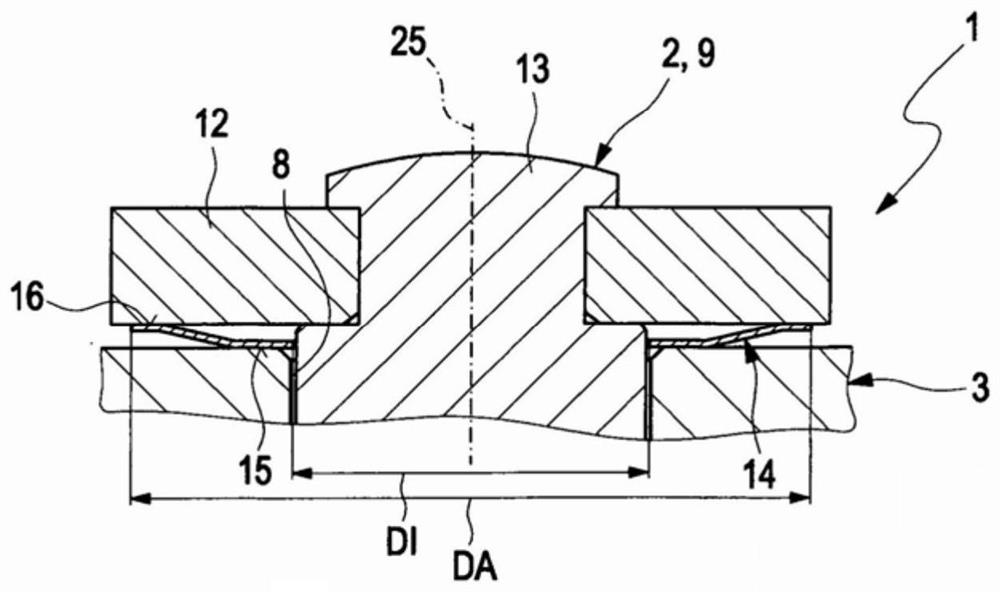

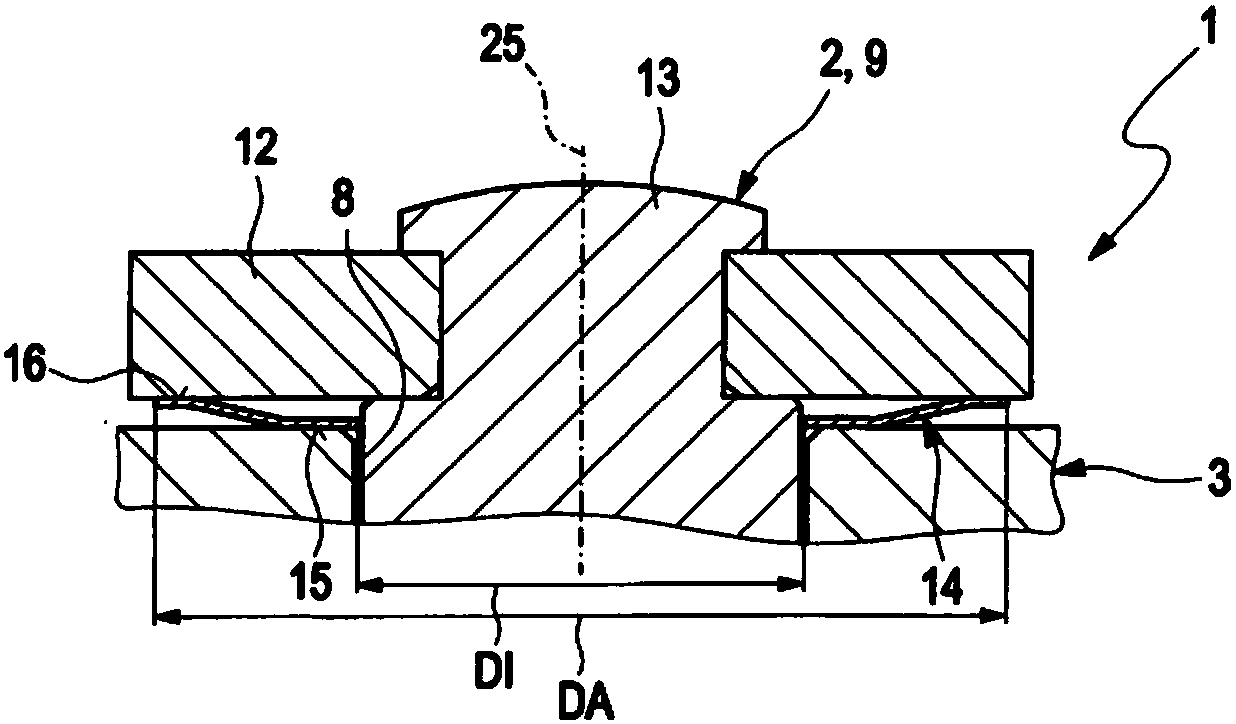

Control valve for controlling a medium, in particular a fuel

ActiveCN107304742ASmall regulationSimple structureSpindle sealingsOperating means/releasing devices for valvesMean diameterEngineering

The present invention relates to a control valve for controlling a medium, in particular a fuel, comprising a sealing seat (2), a valve member (3) which releases and closes a passage (14) on the sealing seat (2), an actuator (4) for actuating the Valve member (3), and a bellows (5) which is fixed to the valve member (3), wherein the valve member (3) in the interior of the bellows (5) is arranged, wherein an outermost diameter (D1) of the sealing seat (2) is equal to a mean diameter (D2) of the bellows (5).

Owner:ROBERT BOSCH GMBH

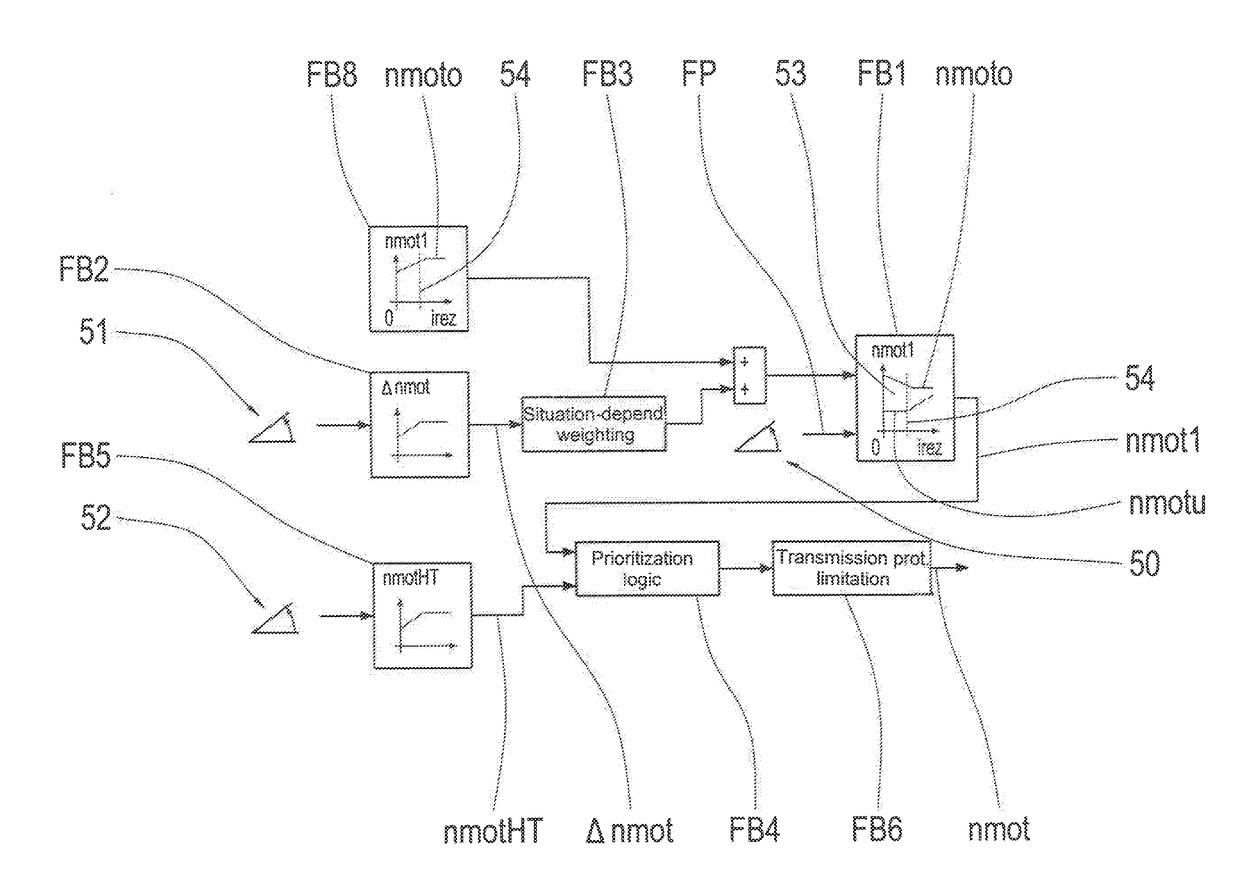

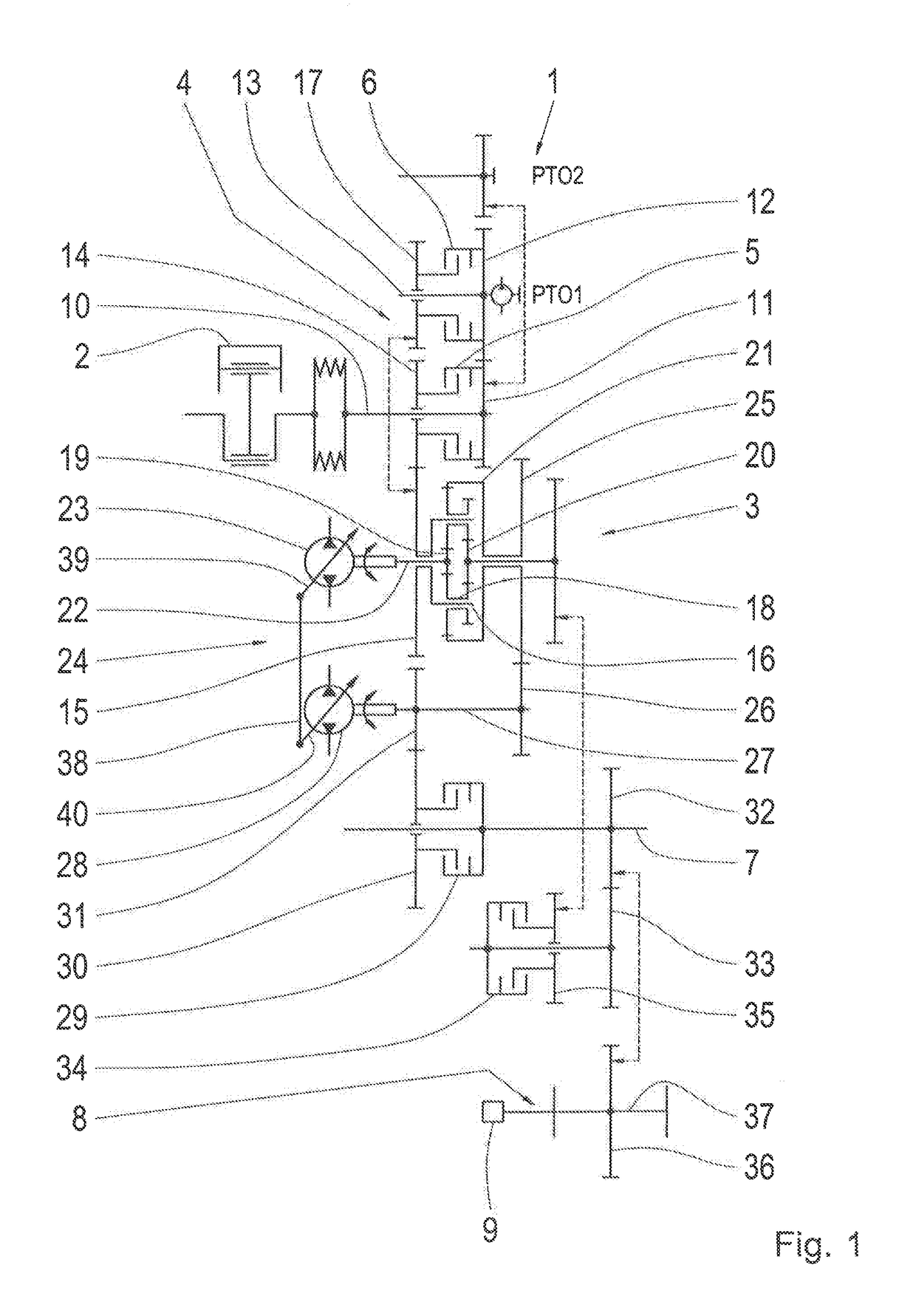

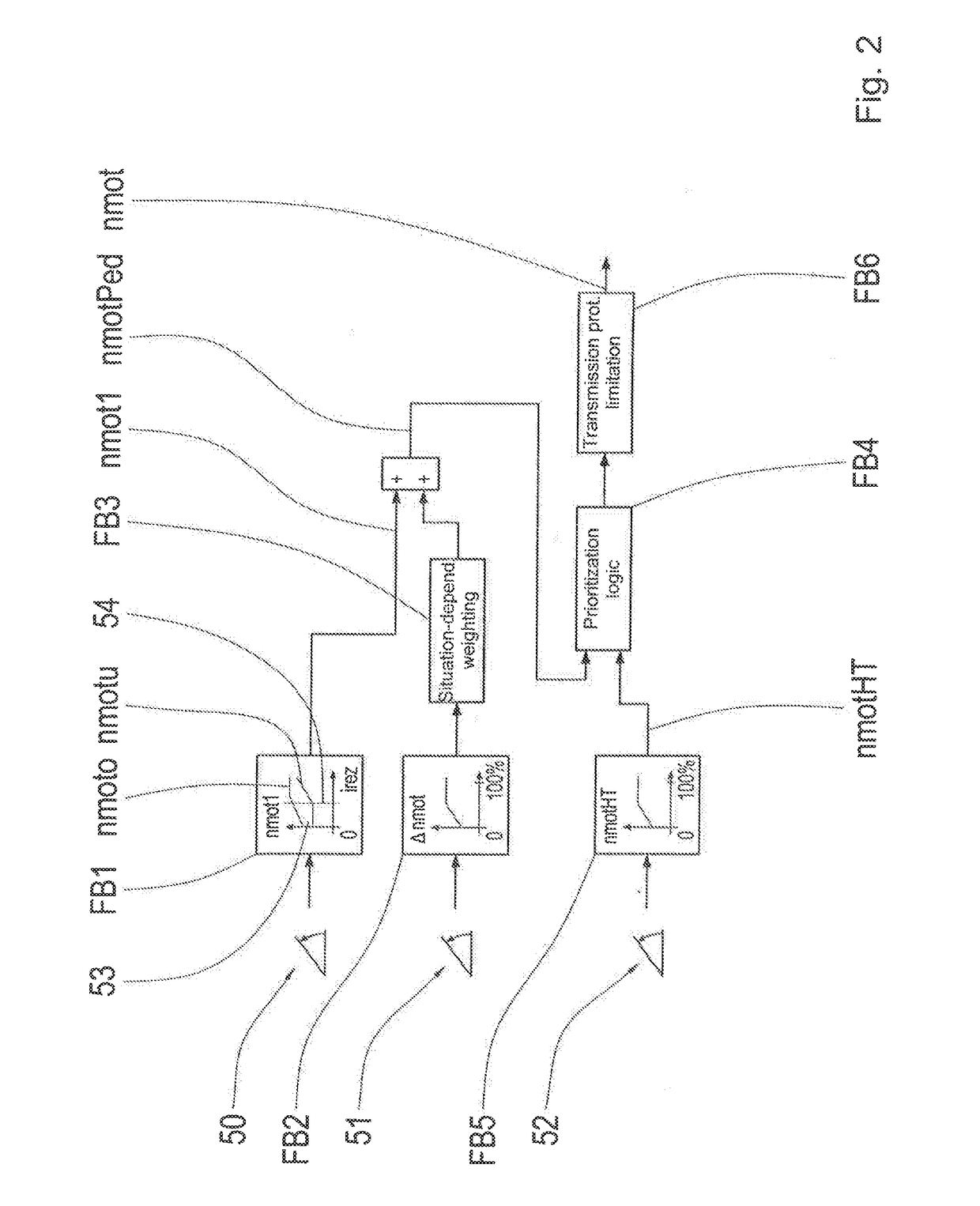

Operating method for a vehicle drive train of a working machine including a drive motor, a transmission and an output

ActiveUS20170203761A1Increase speedLittle controlElectrical controlGearing controlVariatorDrive motor

A method for the operation of a vehicle drive-train of a working machine having a drive motor, a transmission whose transmission ratio can be varied continuously, and a drive output. A rotational speed (nmot) of the drive motor can be varied by the driver, by the driver's actuation of a first control element (50), within a rotational speed range (53) delimited by an upper characteristic line (nmoto) and a lower characteristic line (nmotu). The characteristic lines (nmoto, nmotu) are functions of a reciprocal transmission ratio (irez) of the transmission. Furthermore, the rotational speed (nmot1) of the drive motor that can be set by the driver by way of the first control element (50), can be influenced by the driver's actuation of a second control element (51) and as a function of an operating condition of the working machine.

Owner:ZF FRIEDRICHSHAFEN AG

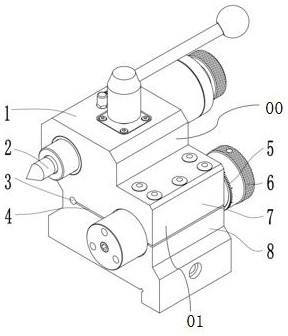

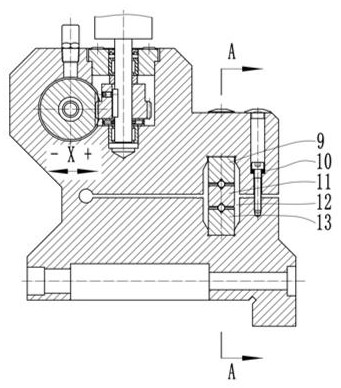

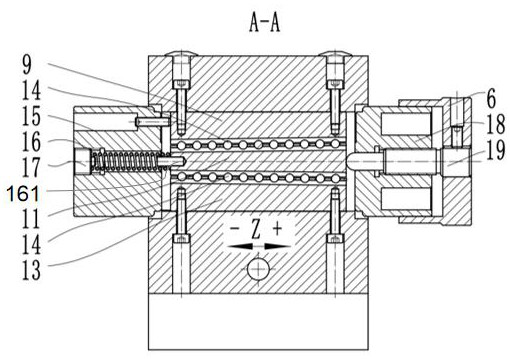

High-precision center fine-adjustment grinding machine tailstock

The invention belongs to the technical field of machine tools, and provides a high-precision center fine-adjustment grinding machine tailstock which comprises a first body and a second body. A through hole and a horizontal gap are formed in the first body, the through hole is parallel to the axis of the center, and the horizontal gap is connected with the through hole, runs through the second body and divides the second body into a tailstock upper part and a tailstock lower part. The second body is provided with a wide groove, wherein the center line of the wide groove is coplanar with the horizontal gap and parallel to the through hole, and an adjusting mechanism is arranged in the wide groove and provided with a wedge block. According to the scheme, the adjusting mechanism of the wedge-shaped structure is adopted, compared with a mechanism which directly adopts screw rod rotation to enable the upper part to deform, the high-precision center fine-adjustment grinding machine tailstock can avoid the creeping phenomenon, and adjustment is more sensitive; and the stress of a screw rod in the feeding mechanism is far smaller than that of a screw rod in the prior art, so that the adjusting force of the screw rod during operation is reduced, and operation is more convenient.

Owner:陕西诺贝特自动化科技股份有限公司

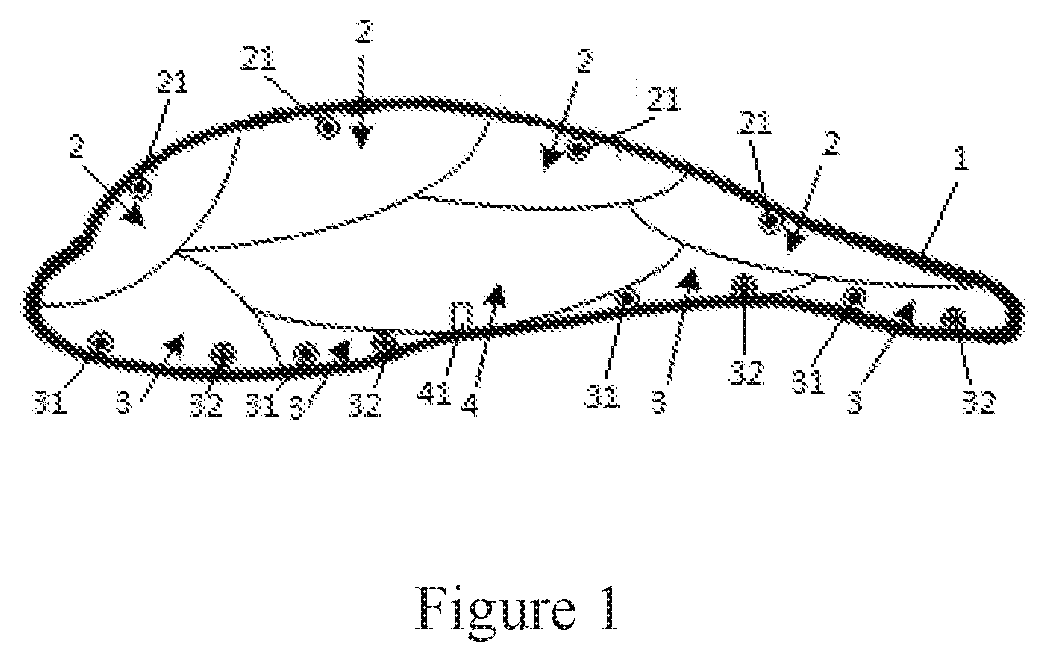

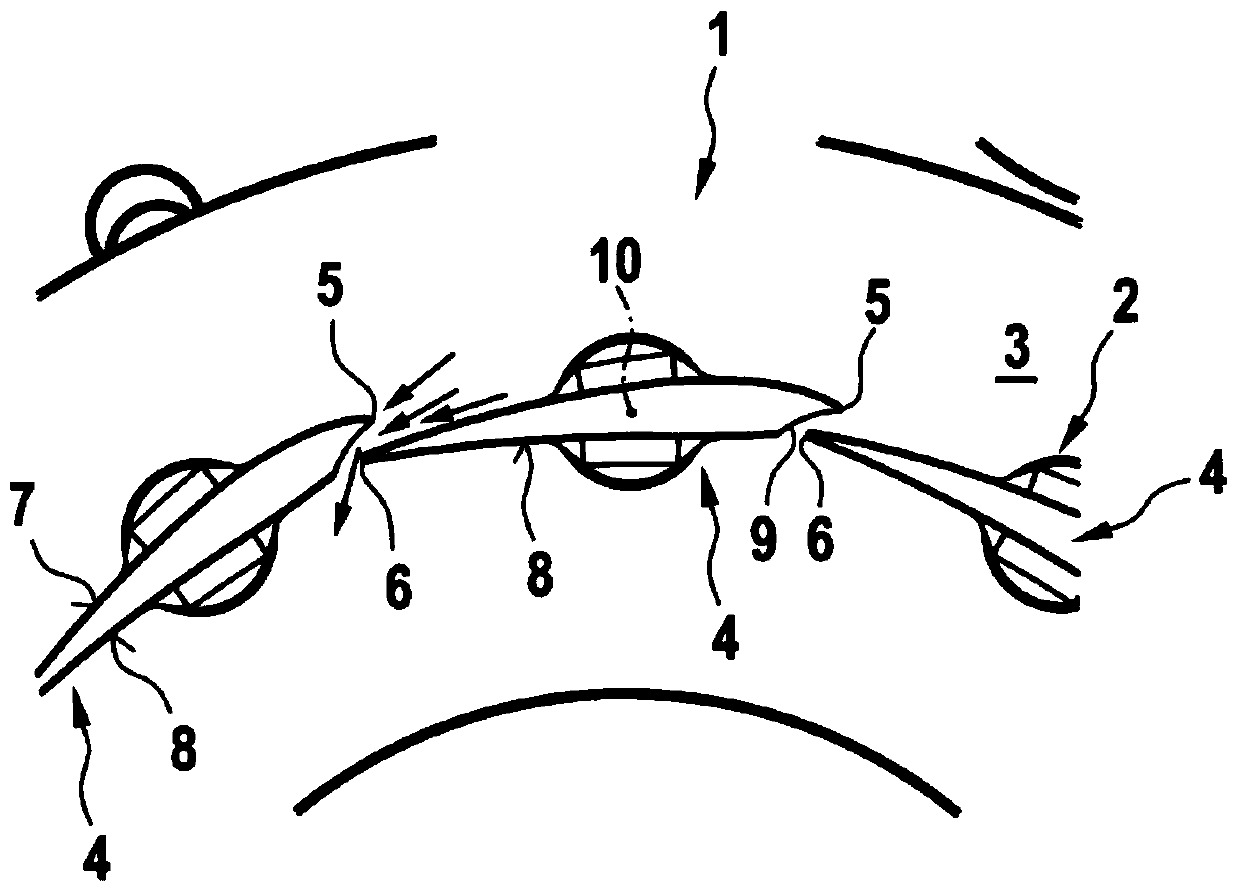

Bionic stratospheric airships

ActiveUS20190359309A1Reduces aerodynamic dampingImprove aerodynamic performanceNon-rigid airshipsGas-bag arrangementsBionicsLiquid state

The present invention discloses bionic stratospheric airships, relate to the technical field of aircrafts. the hull shape of the bionic stratospheric airship is obtained by lofting the shape of physalia physalis; one or more buoyancy gasbags, one or more ballonets, and a heat regulating gasbag are provided inside the hull; the buoyancy gasbags are filled with lighter-than-air gas and are provided at an upper layer inside the hull; the ballonets are filled with air and are provided at a lower layer inside the hull; the heat regulating gasbag is provided at a middle layer inside the hull and is filled with a working medium reversibly regulated between a gas state and a liquid state; and a thermodynamic cycle device for heating or pressurizing the working medium is provided inside the heat regulating gasbag.

Owner:NAT UNIV OF DEFENSE TECH

Control valves for controlling media, especially fuels

ActiveCN107304742BSmall regulationSimple structureSpindle sealingsOperating means/releasing devices for valvesEngineeringControl valves

The invention relates to a control valve for controlling a medium, especially a fuel, said control valve comprising: a sealing seat (2); a valve element (3), which is released on said sealing seat (2) and a closing passage (14); an actuator (4) for manipulating said valve element (3); and a bellows (5), said bellows being fixed on said valve element (3), wherein said The valve element (3) is arranged inside the bellows (5), wherein the outermost diameter (D1) of the sealing seat (2) is as large as the average diameter (D2) of the bellows (5).

Owner:ROBERT BOSCH GMBH

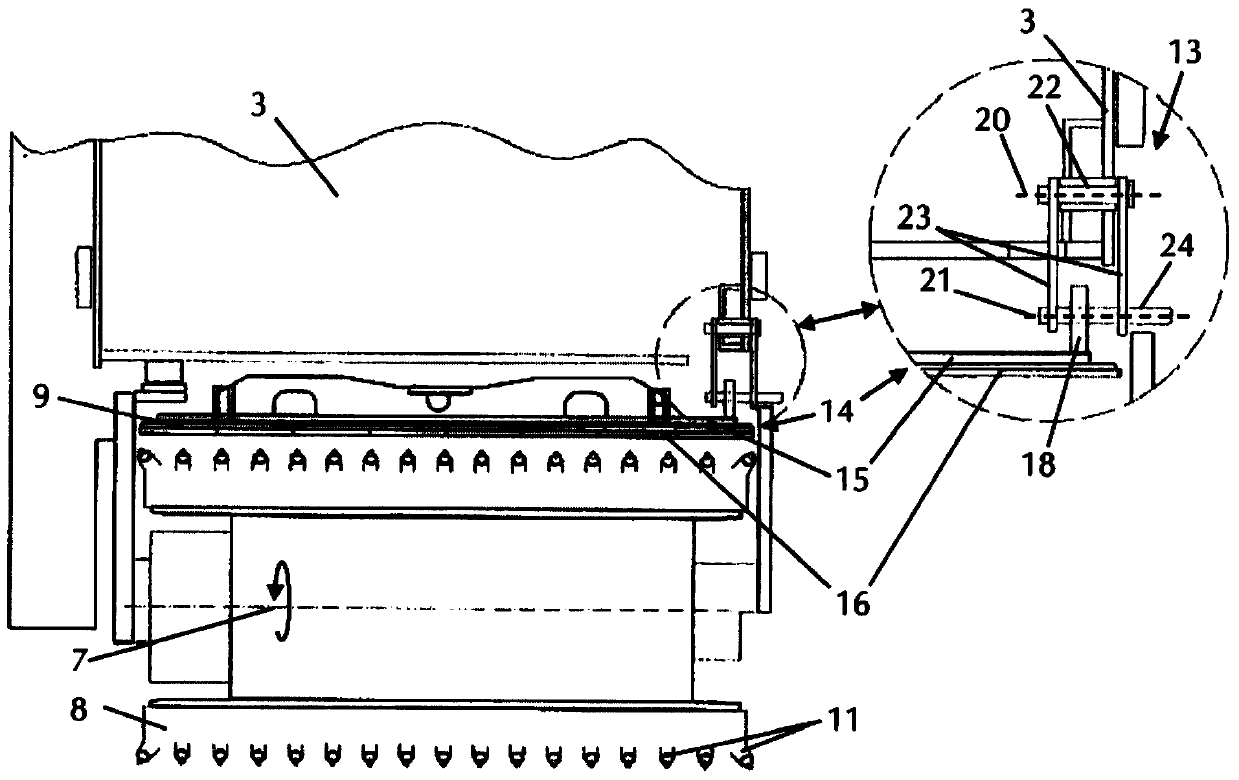

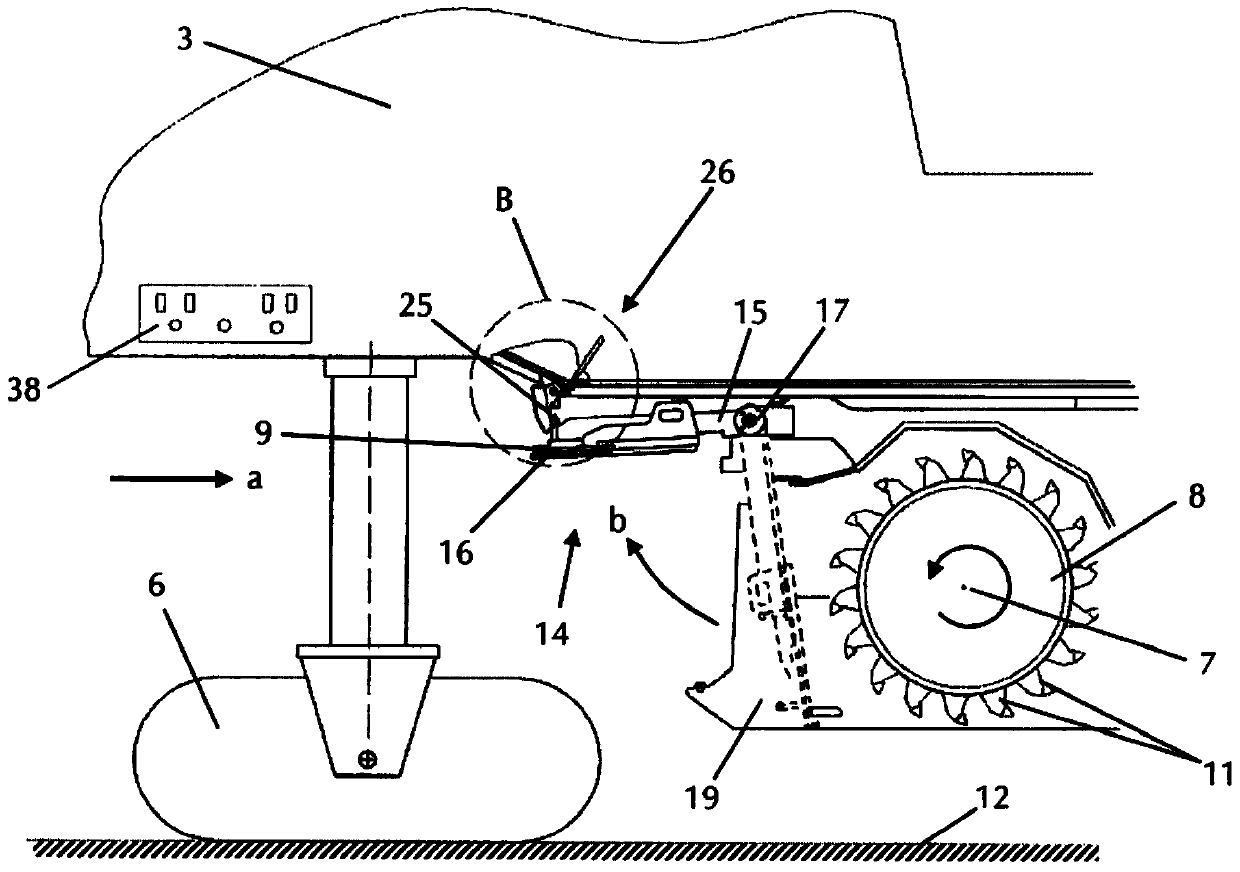

Ground milling machine with means for locking milling roller box door in maintenance position

InactiveCN104047220BEasy to operateSmall retentionRoads maintainenceOpen-pit miningMachine maintenancePulp and paper industry

The invention relates to a ground milling machine, in particular a road milling machine, finishing machine, stabilizer or surface mining machine, said ground milling machine having: a milling roller; a milling roller box with a scraping device, The scraping device forms the rear wall of the milling roller box in the working direction and is pivotable between a working position in which the scraping device closes the milling roller box and a maintenance position in which the scraping device closes the milling roller box. In the position, the scraping device opens the access to the inner cavity of the milling roller box; the locking device, the locking device can releasably fix the scraping device in the maintenance position; and the operating element, after manually operating the operating element, The locking device releases the scraper device again, wherein an operating element for actuating the locking device is provided on two opposite longitudinal sides of the ground milling machine.

Owner:BOMAG

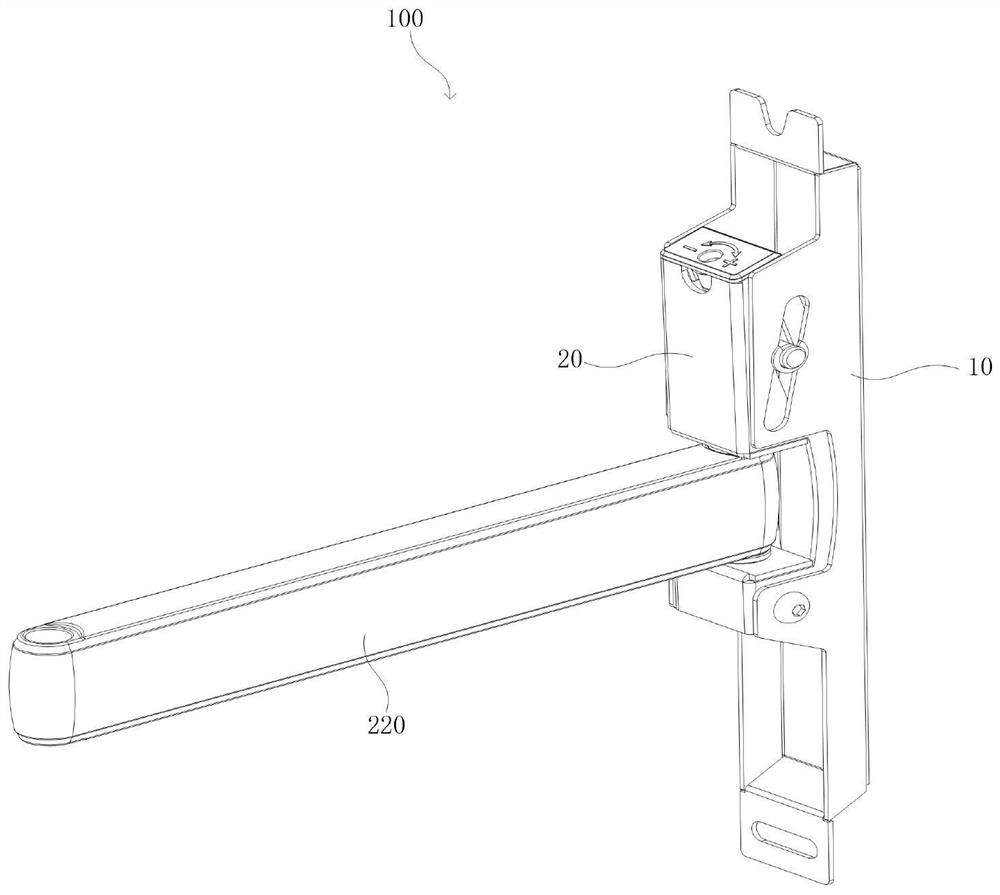

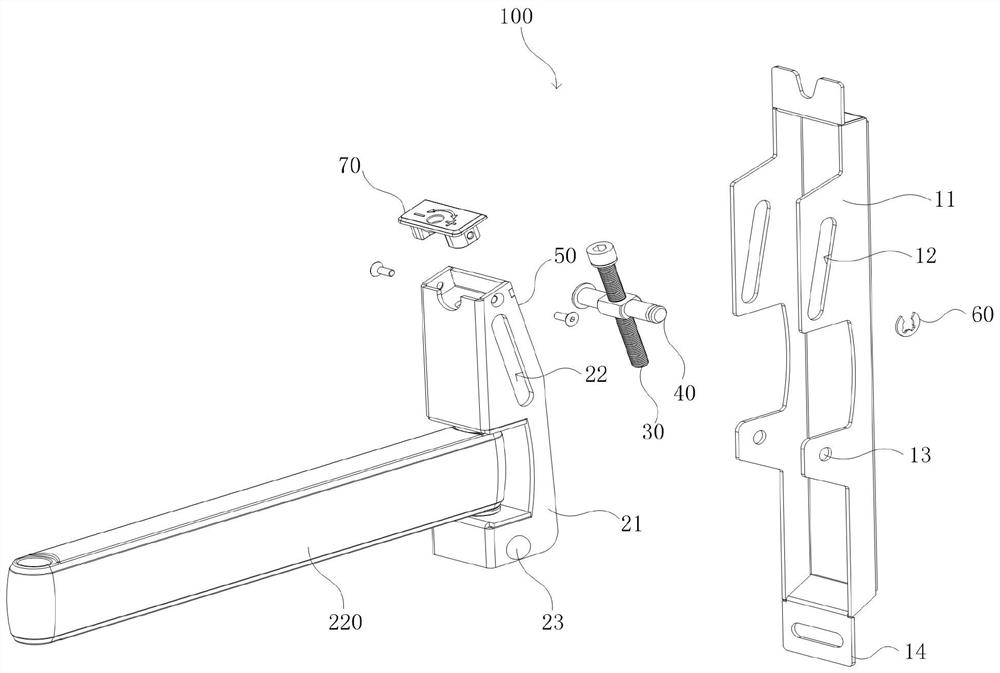

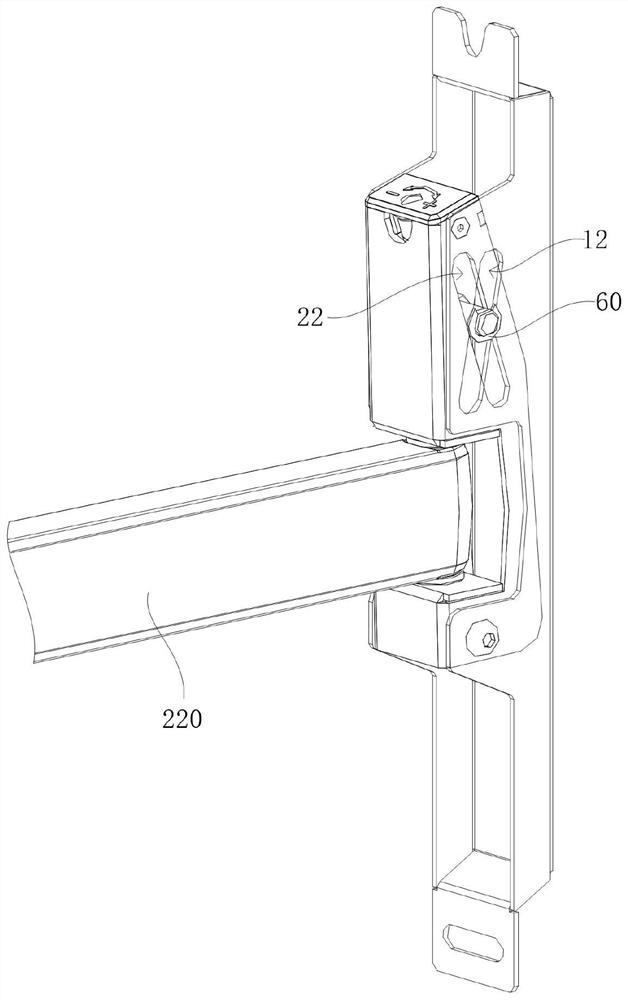

Angle adjusting device, displayer support and display device

PendingCN112747232AEasy to operateSmall regulationStands/trestlesIdentification meansDisplay deviceEngineering

An embodiment of the invention discloses an angle adjusting device, a displayer support and a display device. The angle adjusting device comprises a mounting part, a fixing part, a linkage shaft and an adjusting shaft; the mounting part is provided with a mounting panel and a first side plate connected to one side of the mounting panel; the first side plate is provided with a first adjusting hole; the fixing part is provided with a second side plate; the second side plate is provided with a second adjusting hole; when the second side plate and the first side plate are matched in a staggered mode, the first adjusting hole and the second adjusting hole form a crossed position; the linkage shaft is arranged in the crossed position in a penetrating manner and is provided with a first threaded connecting piece; the adjusting shaft is provided with a second threaded connecting piece matched with the first threaded connecting piece; and when the adjusting shaft rotates, the second threaded connecting piece is matched with the first threaded connecting piece, the linkage shaft moves along the second adjusting hole, and the crossed position is changed. The angle adjusting device is convenient to operate, small in adjusting force, capable of being operated by one person, simple in structure, low in cost and reliable in performance.

Owner:NINGBO TUOTUO RIVER DESIGN CO

A fast knife structure with adjustable stiffness at the distal knife end

ActiveCN110153768BAvoid plastic deformationSmall regulationFeeding apparatusStructural engineeringMechanical engineering

Owner:SHANDONG UNIV

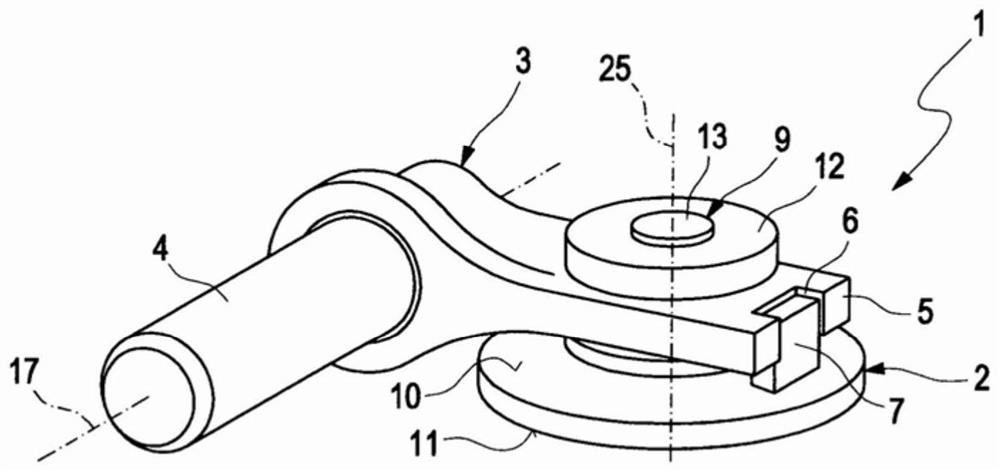

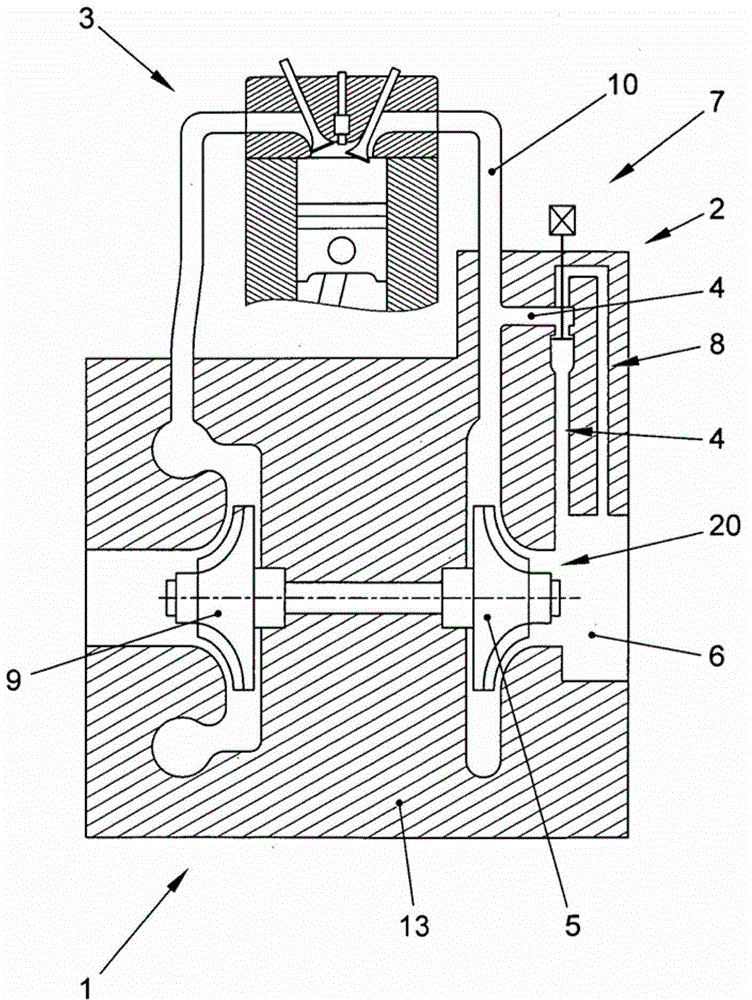

Regulating device for exhaust gas turbocharger and exhaust gas turbocharger

ActiveCN108474293BSmall regulationReduced service lifeInternal combustion piston enginesShaftsTurbochargerExhaust fumes

The invention relates to a control device for an exhaust gas turbocharger, the control device having an exhaust gas guide section that can flow through, the exhaust gas guide section having a bypass channel for bypassing the exhaust gas guide a turbine rotatably arranged in the segment; and an adjustment arm (3) for receiving a valve element (2) arranged to open or close the flow cross-section of the bypass passage, wherein The adjusting arm (3) is accommodated movably in the exhaust gas guide section, and a spring element (14) is provided therein for at least securing the positioning of the valve element (2) on the adjusting arm (3) . According to the invention, the spring element (14) is designed in a radially slidable manner for reducing the adjusting force.

Owner:IHI CHARGING SYST INT

A device for adjusting the magnetic force of a printing magnetic table by adjusting the screw and the cylinder element

ActiveCN105291568BSmall regulationAvoid breakingScreen printersMagnetic tension forceTransmitted power

The invention discloses a device for adjusting the magnetic force of a printing magnetic table in cooperation with an adjusting screw and a cylinder element, which comprises a cylinder element installed at the bottom of a magnetic table support body and a rocker arm pivotally connected to the magnetic table support body; the bottom of the rocker arm The end is connected with the central axis of the cylinder element through double clevis, and the top of the rocker arm is connected with the magnetic table. The magnetic adjustment device also includes a gear set installed on the outer wall of the side beam, a transmission rod connected with the driving gear in the gear set, and an adjusting screw connected with the driven gear in the gear set; one end of the adjusting screw is screwed on the driven gear In the threaded hole, the other end is connected to the bottom end of the double clevis through an anti-wear device. Through the above-mentioned technical solution, a small adjustment force applied to the transmission rod from the outside can drive the adjustment screw to retreat or advance through the gear set, and the anti-wear device can transmit the power to the rocker arm without contacting the adjustment screw with the double clevis. Then the central axis is stretched or retracted to accurately and effectively adjust the magnetic force of the magnetic table.

Owner:HUZHOU HUISHENG MACHINERY

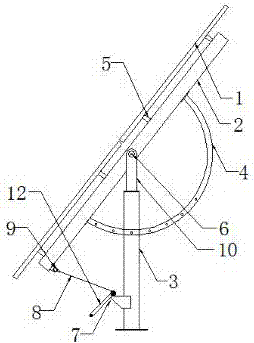

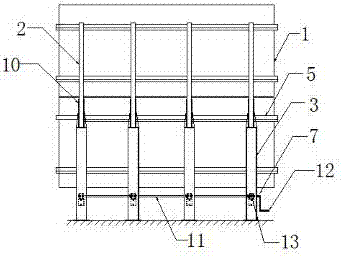

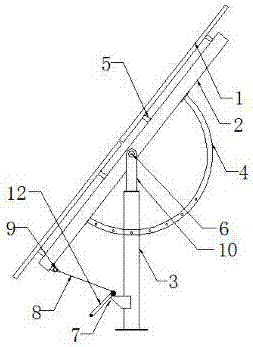

Eccentric fixed adjustable support

The invention discloses an eccentric fixed adjustable support. The eccentric fixed adjustable support comprises two photovoltaic back plates, support stand columns and support adjustment round strutting rods. Multiple support sandalwood strips are uniformly arranged at one side of the two photovoltaic back plates. Multiple support inclined beams are uniformly arranged at one side of the multiple support sandalwood strips. The two sides of the middles of the support inclined beams are each provided with a fixing plate. Every two fixing plates are fixedly arranged at the two sides of the top endof the corresponding support stand column. An adjustment winch assembly is arranged at one side of the bottom of each support stand column. According to the eccentric fixed adjustable support, by means of cooperation between the adjustment winch assemblies and a steel wire rope, the included angle between the photovoltaic back plates and the horizontal plane can be adjusted in a fast and labor-saving manner by rotating a rotary handle and locked by making the support adjustment round strutting rods penetrate a fixing shaft; and according to the eccentric design of the eccentric fixed adjustable support, an upward force moment exists on the rotating part all the time, when the fixing shaft is removed and the adjustment winch assemblies are loosened, the adjustment winch assemblies rotate to corresponding positions in the opposite direction.

Owner:SUZHOU GAOCHUANGTE NEW ENERGY SOURCES DEV CO LTD

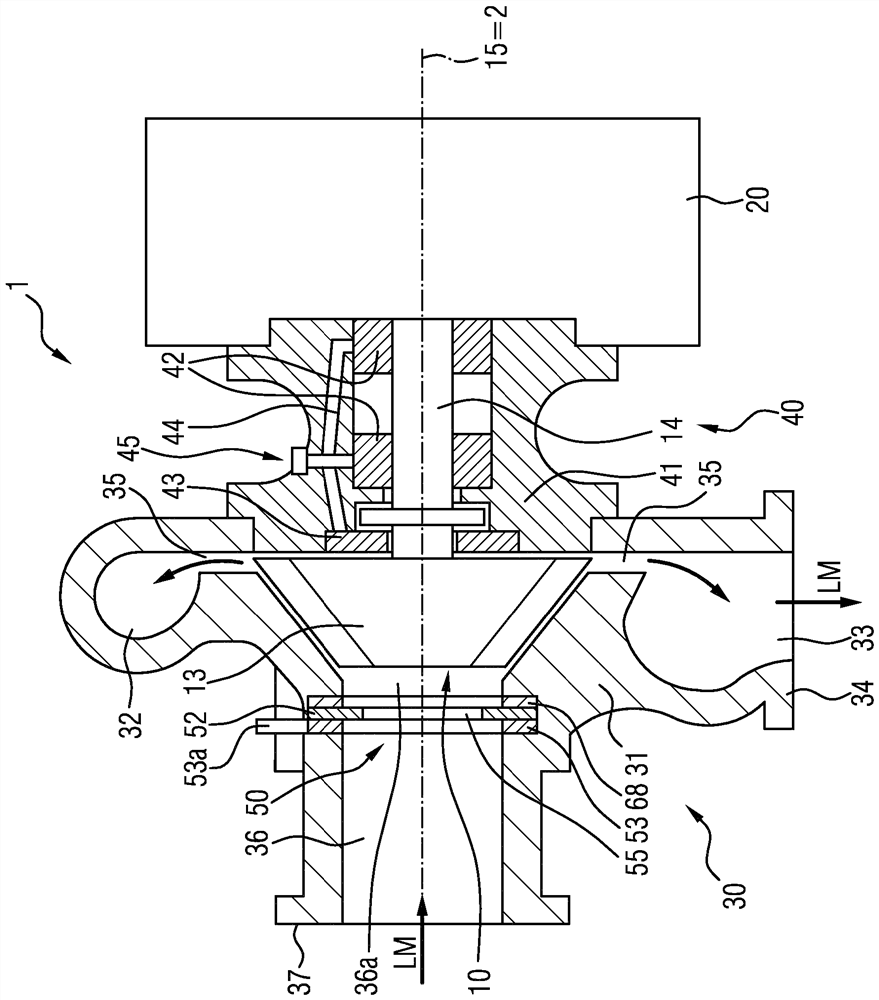

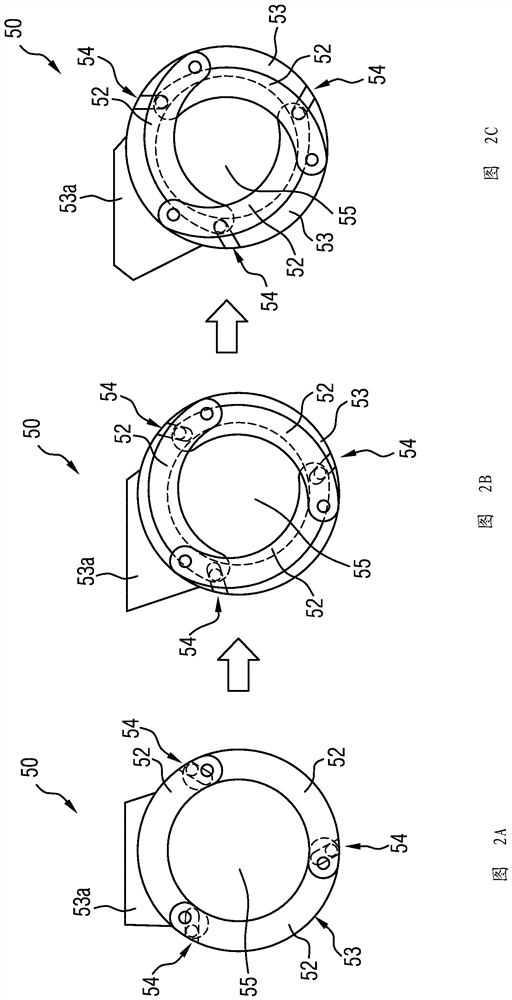

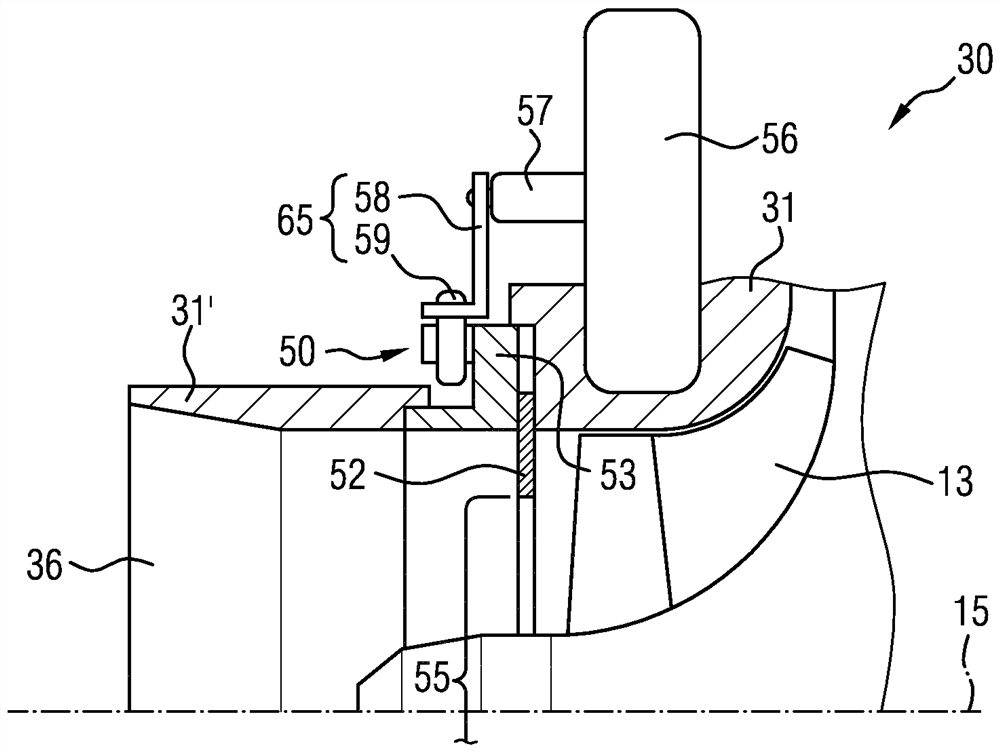

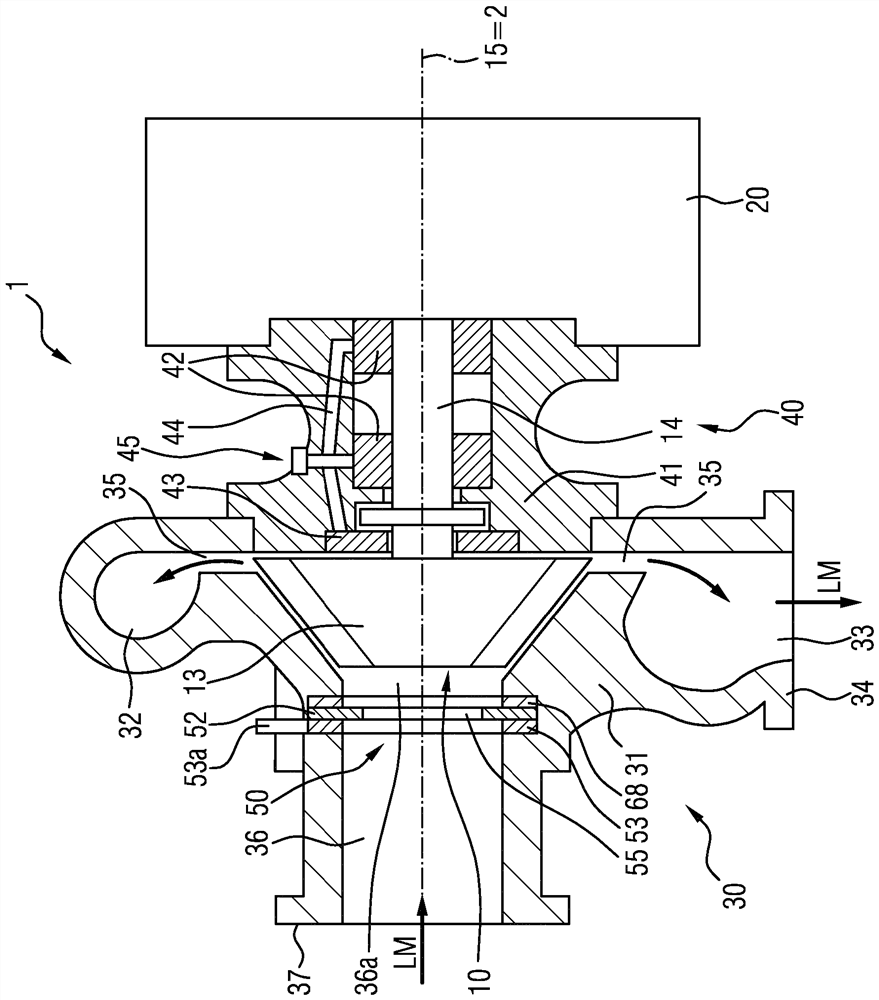

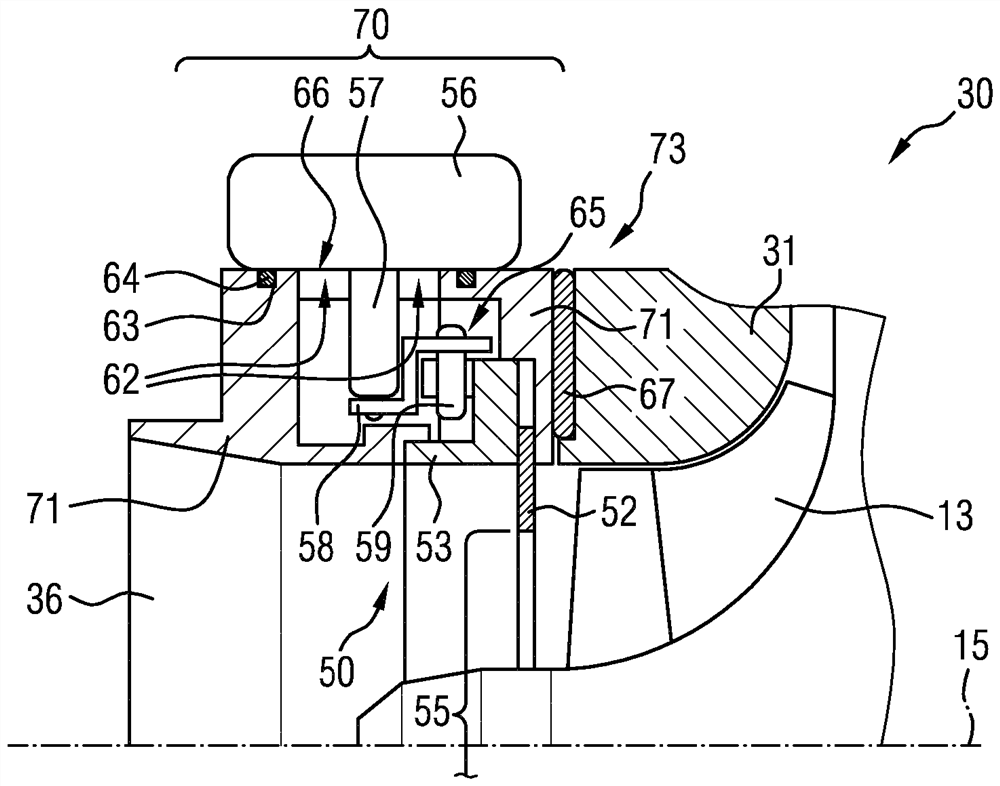

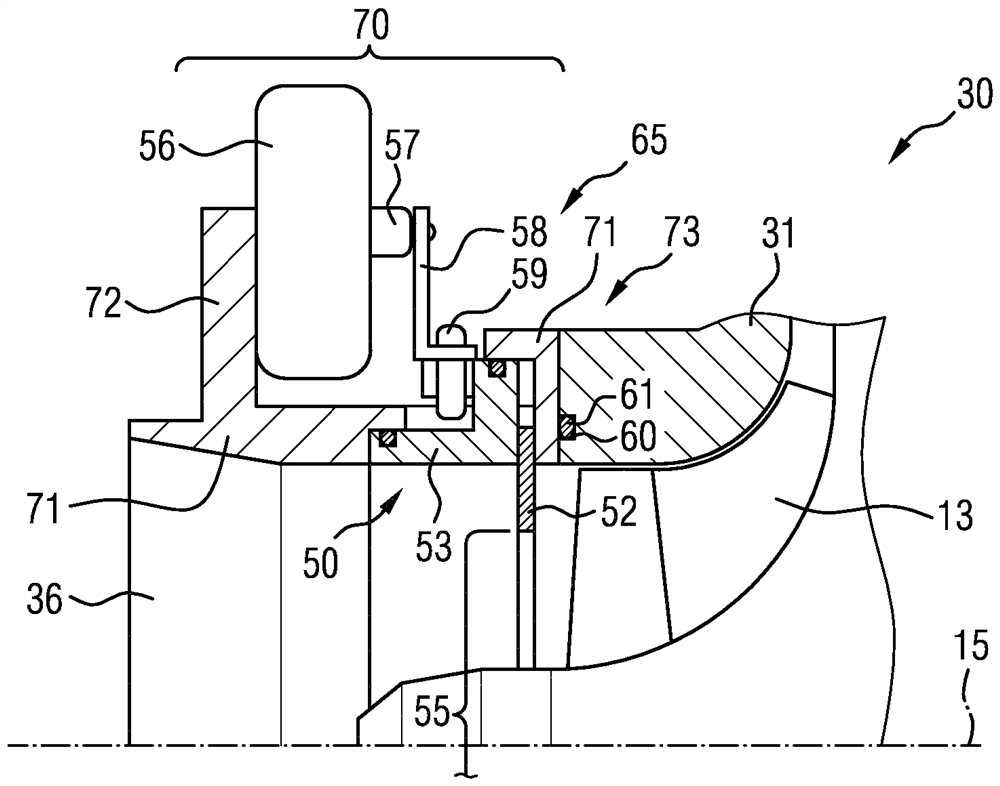

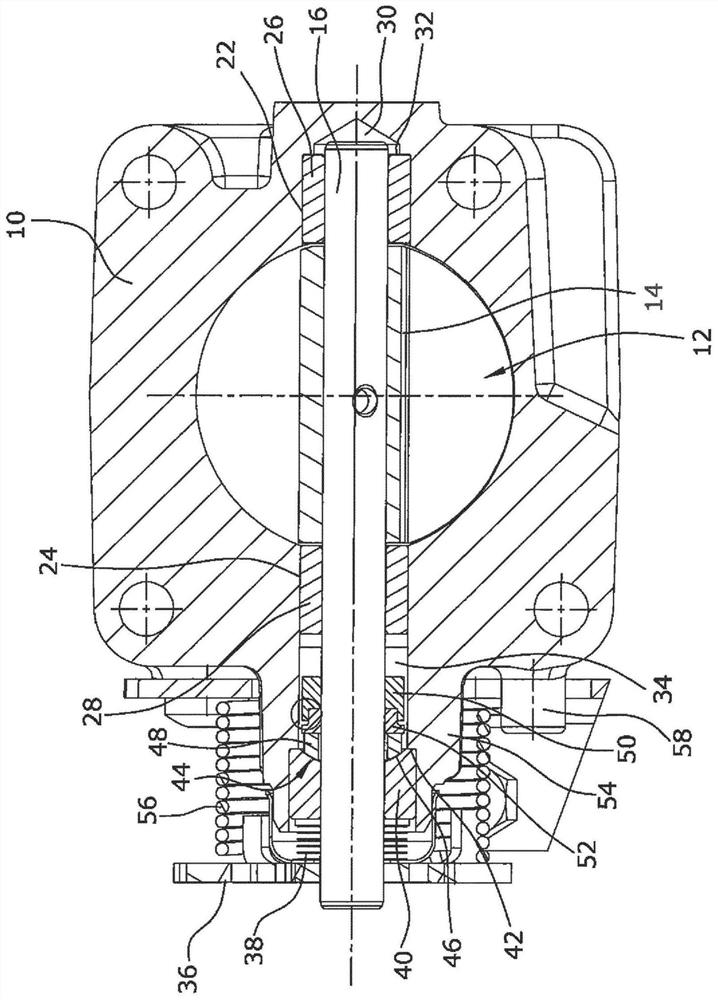

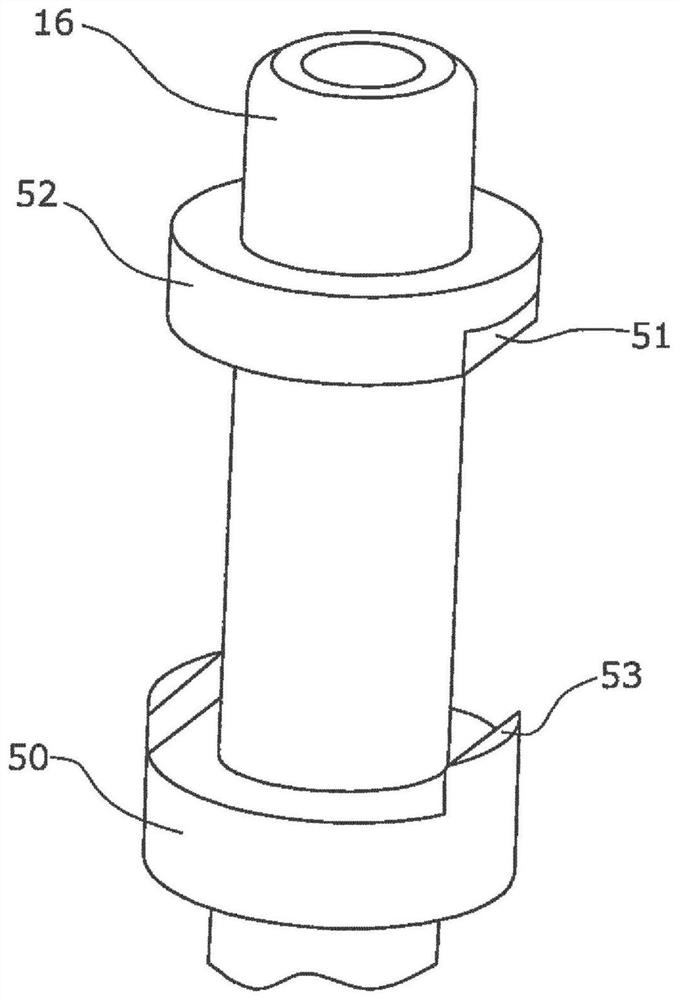

Compressor for a supercharging device for an internal combustion engine and a supercharging device for an internal combustion engine

ActiveCN111201379BIncreased durabilityLow costEngine manufactureInternal combustion piston enginesInternal combustion engineActuator

The invention relates to a compressor (30) of a supercharging device (1) for an internal combustion engine, having: a compressor wheel (13) fixed in rotation to a rotor shaft (14); an air supply channel (36) , for delivering air mass flow (LM) to the compressor wheel (13); an iris diaphragm mechanism (50), arranged upstream of the compressor wheel (13) and having a plurality of lamellae (52), and is designed to close or open the diaphragm hole (55), so that the flow cross-section for the air mass flow (LM) flowing against the compressor wheel (13) can be variably adjusted; the housing (60), It at least partially delimits the air supply channel (36), and is arranged and mounted in the housing (60) with the iris type diaphragm mechanism (50); and the actuator (56), which passes through the The opening (63) is mechanically coupled to the iris diaphragm mechanism (50) to actuate the iris diaphragm mechanism (50), wherein the actuator (56) is disposed on the housing (60) such that the opening (63) It is hermetically closed by means of an actuator (56). The invention also relates to a charging device (1).

Owner:VITESCO TECH GERMANY GMBH

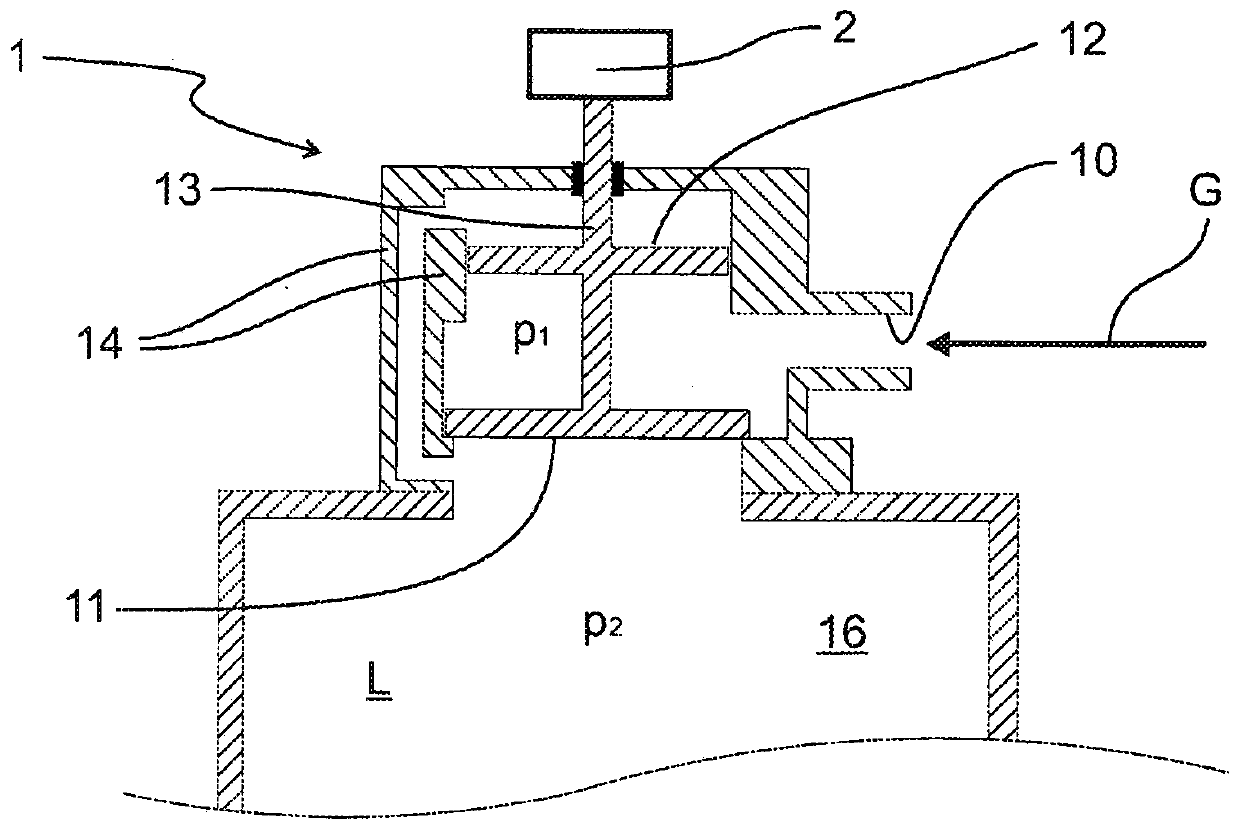

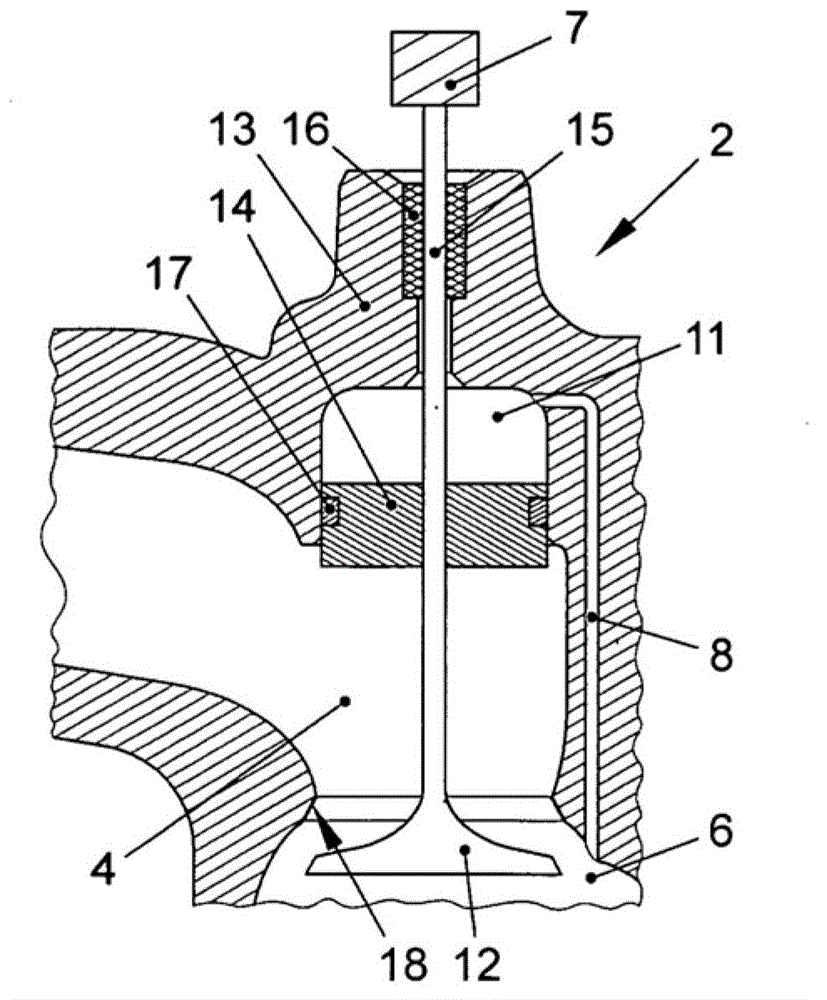

Insert valve for sectional radiator

InactiveCN1246617CSmall regulationSmall sizeFluid heatersOperating means/releasing devices for valvesEngineeringValve seat

An insert valve for a sectional radiator (1), comprising a housing (6) extending through a first section (2), a valve seat (16) cooperating with an externally operated sealing member (17), an inlet duct extending from the periphery of the housing (21), and an outlet duct leading to a second section (3). The sealing element (17) is relieved from pressure. The inlet duct (21) is disposed in a lateral position close to the sealing element (17). The outlet duct (22) is joined to the valve seat (16) on the opposite side to said sealing element (17), thereby providing an insert valve which has a simple design and can therefore be produced at low cost.

Owner:DANFOSS AS

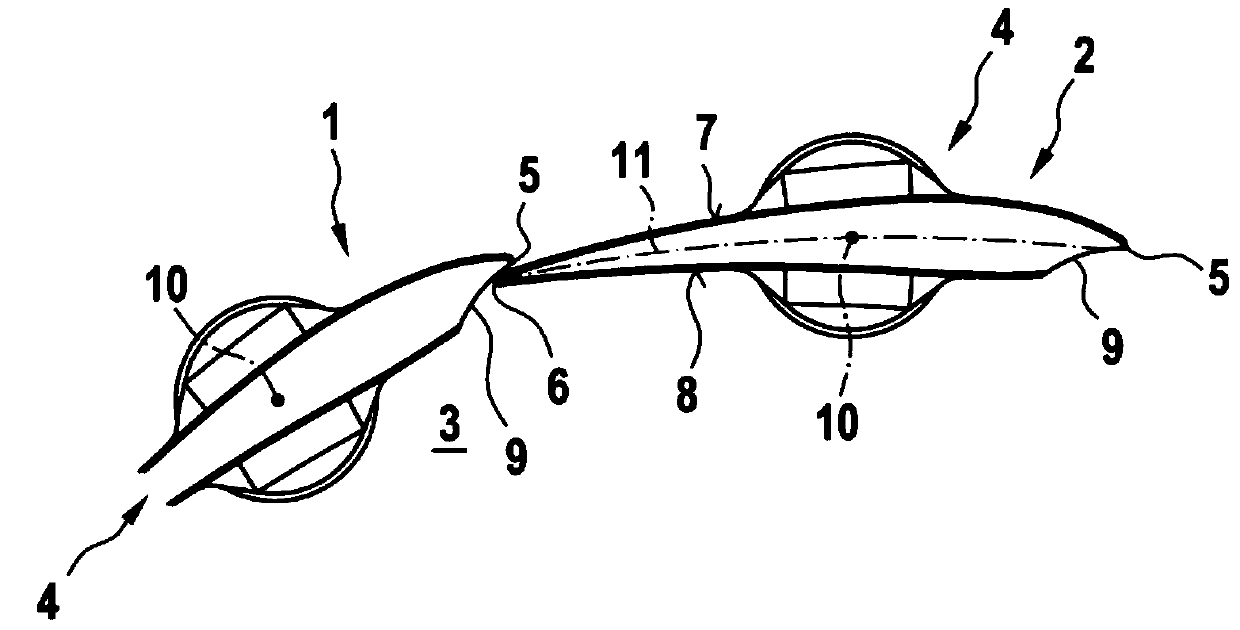

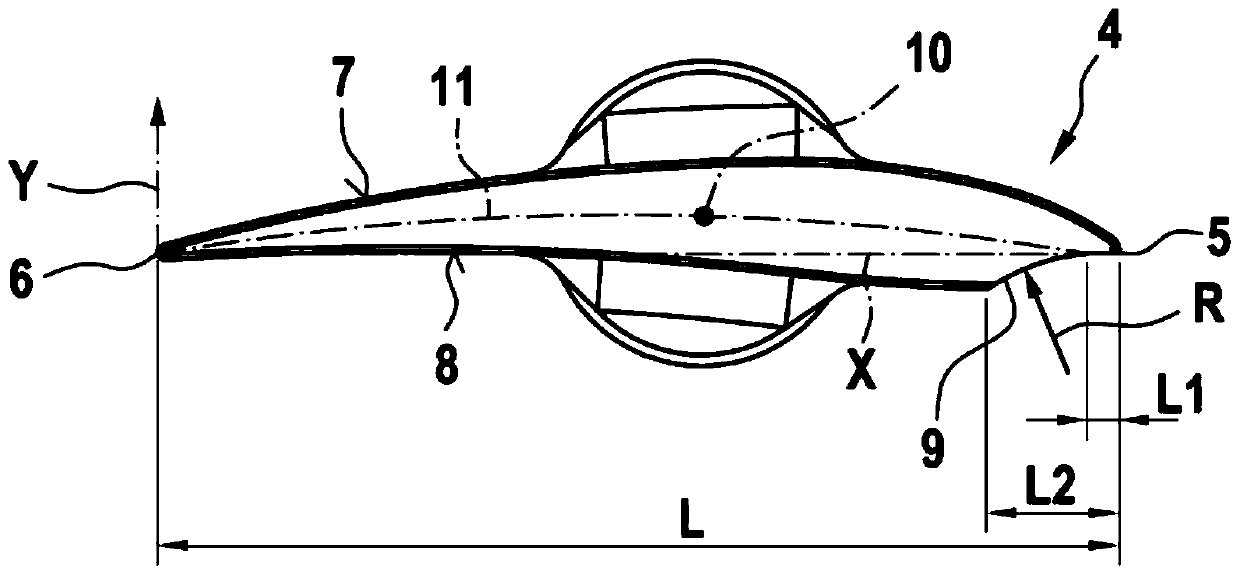

Supercharger device with variable geometry turbine

ActiveCN105986843BGood aerodynamic shapeSpeed up response behaviorBlade accessoriesCombustion enginesVariable geometry turbineClassical mechanics

The invention relates to a supercharger arrangement (1) with a variable geometry turbine (2), in particular an exhaust-gas turbocharger for a motor vehicle, having guide vanes (4) which are rotatably Fitted in the blade bearing ring (3) and has a top side (7) extending in a convex form from the profile nose (5) to the profile end (6). What is essential for the invention here is that the concave groove (9) is arranged on the bottom side (8) of the guide vane (4) at the profile nose (5). In this way, in particular an improved response behavior can be achieved.

Owner:BMTS TECH SHANGHAI CO LTD

Compressor for a supercharger of an internal combustion engine, a throttle module and a supercharger for an internal combustion engine

ActiveCN111133199BIncreased durabilityLow costEngine manufactureInternal combustion piston enginesActuatorControl theory

The invention relates to a compressor ( 30 ) for a charging device ( 1 ) of an internal combustion engine, the compressor ( 30 ) having: - a compressor housing ( 31 ), wherein the compressor wheel ( 13 ) is rotatably coupled Arranged on the rotor shaft (14); - an air feed channel (36) for directing the air mass flow (LM) to the compressor wheel (13). The compressor (30) has a throttle module (70) with: - an iris diaphragm mechanism (50) arranged upstream of the compressor wheel (13) and has a plurality of lamellae (52) and is designed to close or open the diaphragm orifice (55) through the lamellae (52), allowing variable adjustment of the air mass flow (LM) into the compressor wheel (13) flow cross-section; - a throttle module housing (71) at least partially delimiting the air feed passage (36) and on which the iris diaphragm mechanism (50) is arranged and mounted in and / or on the throttle module housing (71); and - the actuator (56) mounted on the throttle module housing (71) And mechanically coupled to the iris diaphragm mechanism (50) to actuate it. The throttle module (70) is formed as a structural unit which is separated from the compressor housing (31) and is flange-mounted on the compressor housing (31) via the throttle module housing (71). The invention also relates to a throttle module (70) and a charging device (1).

Owner:VITESCO TECH GERMANY GMBH

Constant pressure control valve of large-flow high-pressure plunger pump

The invention discloses a constant pressure control valve of a large-flow high-pressure plunger pump. The constant pressure control valve is characterized by comprising a valve body, a mounting base, a valve element assembly, a limiting ejector rod assembly and a pressure adjusting spring assembly, wherein a main body of the pressure adjusting spring assembly is located in the mounting base; the valve element assembly comprises a transition valve sleeve, a main sliding valve element and an inner valve element. The constant pressure control valve has the advantages that by increasing the diameter of the valve body, the diameter of the main sliding valve element in the valve body is increased, so that the response speed of the high-pressure plunger pump is increased; the inner valve element is placed in the main sliding valve element, so that the axial thrust of the main sliding valve element under the high-pressure working condition can be reduced, and the control force of the pressure adjusting spring assembly is reduced; when the diameter of the main sliding valve element is increased, the thrust for pushing the main sliding valve element can be kept unchanged by reducing the sectional area of the inner valve element, so that the adjusting force of a spring is small, and the appearance of the pressure adjusting spring assembly is compact; and when the set pressure needs to be remotely controlled and adjusted, remote pressure control over pressure oil introduced into the pressure adjusting spring assembly can be achieved only by disassembling the inner valve element in the valve element assembly.

Owner:宁波恒力液压股份有限公司

Adjusting device for a turbocharger, and turbocharger

ActiveCN108474293AReduced service lifeExtended service lifeInternal combustion piston enginesShaftsTurbine wheelEngineering

The invention relates to a control device for an exhaust turbocharger, comprising an exhaust gas conducting section through which fluid can flow and which includes a bypass duct for bypassing a turbine wheel that is rotatably arranged in the exhaust gas conducting section, and comprising an adjusting arm (3) for accommodating a valve element (2) provided for opening or blocking a flow cross-section of the bypass duct; the adjusting arm (3) is movably accommodated in the exhaust gas conducting section; furthermore, a flexible element (14) is provided at least for securing the valve element (2)in place on the adjusting arm (3). According to the invention, the flexible element (14) is designed so as to be radially slidable in order to reduce adjustment forces.

Owner:IHI CHARGING SYST INT

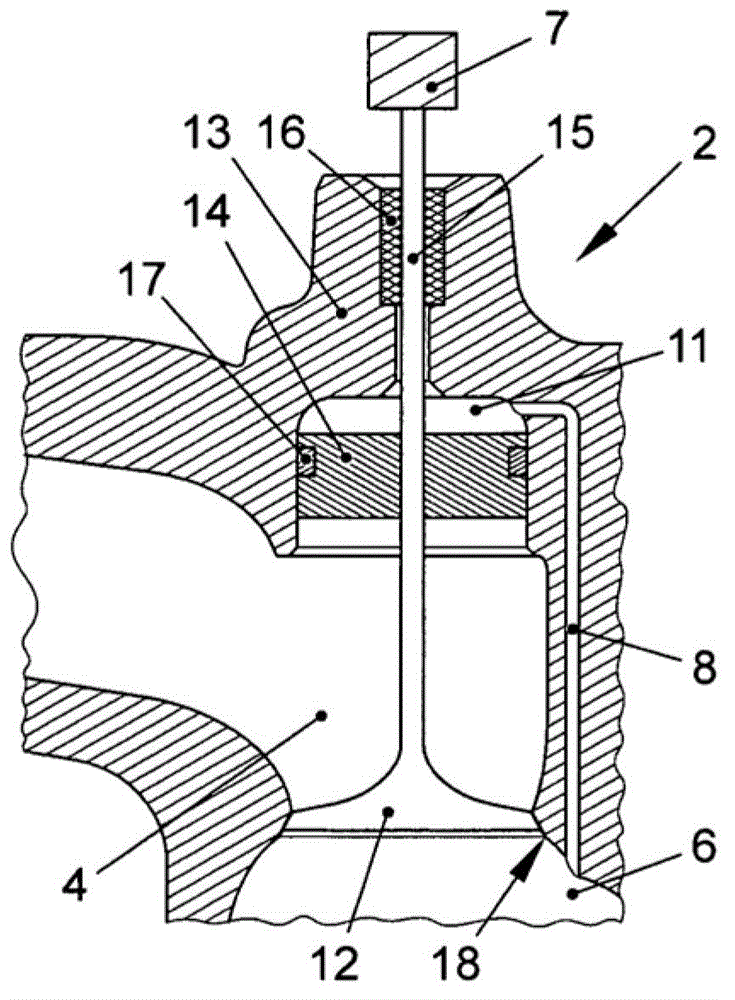

Exhaust turbocharger with bypass valve

ActiveCN103097689BLow power consumption requirementsSmall regulationInternal combustion piston enginesGas turbine plantsExhaust gasValve stem

An exhaust-gas turbocharger is embodied with a bypass valve which is disposed in a bypass duct of a turbine between an exhaust-gas pressure line and an outlet cross section of the turbine of the exhaust-gas turbocharger and which is connected to an actuating device for controlling the throughput of exhaust-gas through the bypass duct. Through the bypass valve, a partial flow of the exhaust-gas can be guided past the turbine on demand. The bypass valve has a valve head and a valve stem. The bypass valve is axially movably held with the valve stem. The valve head, in a closed state of the bypass valve, can be placed against a valve seat in order to close the bypass duct in a gas-tight and pressure-tight manner. The side of the valve head that is connected to the valve stem faces the exhaust-gas pressure line.

Owner:VOLKSWAGEN AG

Wastegate devices for internal combustion engines

ActiveCN109312669BHigh chemical resistanceGood sliding performanceExhaust gas recirculationEngine controllersExhaust gasExhaust fumes

An exhaust gas valve device for an internal combustion engine is known, which has a flow housing (10), a valve body (14), a shaft (16), at least one radial bearing (26, 28), a sealing device (44), The flow housing defines a flow channel (12), the valve body (14) is fixed on the shaft, and the shaft (16) is connected to at least one of the flow housing (10) through the radial bearing. Mounted radially in bearing receptacles (22, 24), the sealing device has a ceramic disk (48) and a sleeve (50) fastened to the shaft (16). In order to reduce the coefficient of friction and wear between the axial bearing and the ceramic disk and to improve the tightness, it is proposed that the axial bearing (40) is fixed in the bore (34) and is made of sintered metal powder of an iron alloy with a high chromium content , and has an austenitic and ferritic composite structure with a carbide alloy composition and a uniformly distributed solid lubricant phase, and is axially loaded relative to a ceramic disk (48) which is free to rotate ground around the shaft (16).

Owner:PIERBURG GMBH & CO KG NEUSS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com