Compressor for a supercharger of an internal combustion engine, a throttle module and a supercharger for an internal combustion engine

A booster device and compressor technology, applied in the field of compressors, can solve problems such as low efficiency, achieve the effects of improving durability, reducing assembly and production costs, and reducing structural space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

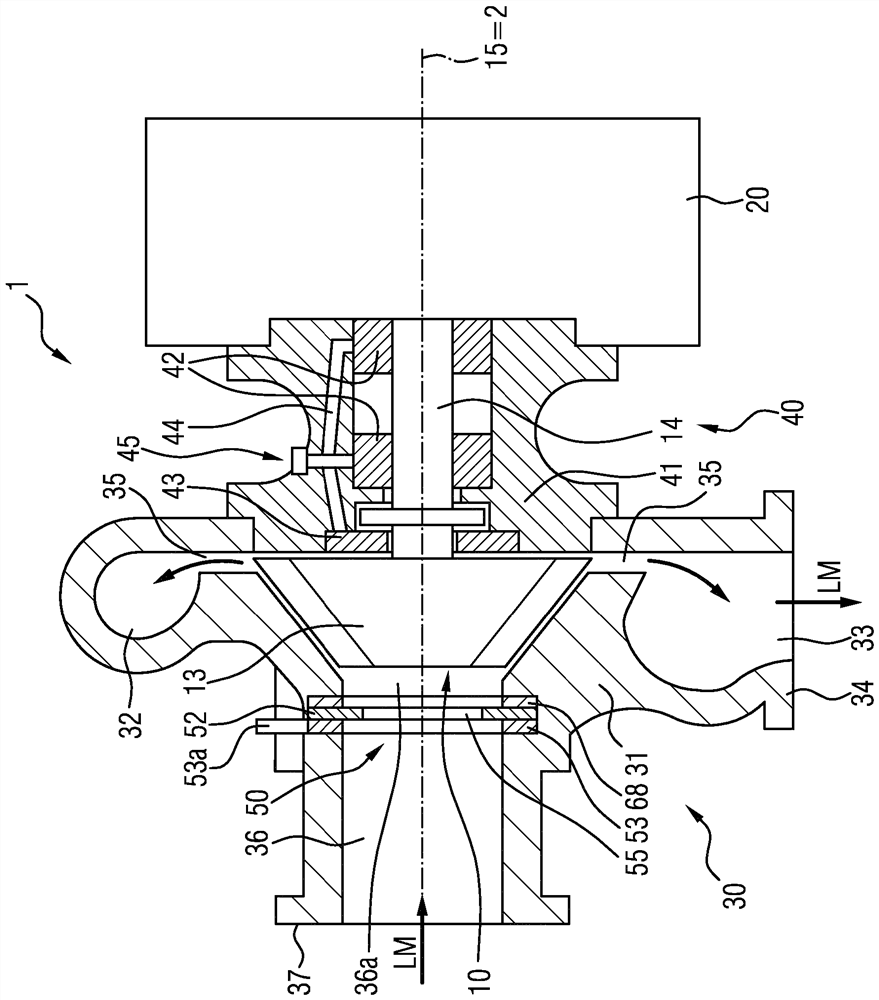

[0057] figure 1 An example of a supercharging device 1 comprising a compressor 30 (in this case a radial compressor), a rotor bearing 40 and a drive unit 20 is schematically shown in a sectional view. Compressor 30 has an optional overrun air recirculation valve (not shown), and air mass flow LM is also indicated by arrows. The so-called charger rotor 10 of the charging device 1 has a compressor wheel 13 (also called compressor wheel) and a rotor shaft 14 (also called shaft). The supercharger rotor 10 rotates during operation about a rotor axis of rotation 15 of a rotor shaft 14 . The rotor axis of rotation 15 and at the same time the supercharger axis 2 (also referred to as the longitudinal axis) are shown by the indicated center lines and identify the axial orientation of the supercharging device 1 . The supercharger rotor 10 is installed, wherein the rotor shaft 14 of the supercharger rotor 10 is situated in the bearing housing 41 via two radial bearings 42 and an axial b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com