Fuel supply system of double fuel tanks of heavy truck

A fuel supply system and fuel tank technology, which is applied to the charging system, liquid fuel feeder, engine components, etc., can solve the problems of increased transportation costs and inability to switch fuel models in time, so as to reduce transportation costs and overcome fuel costs. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

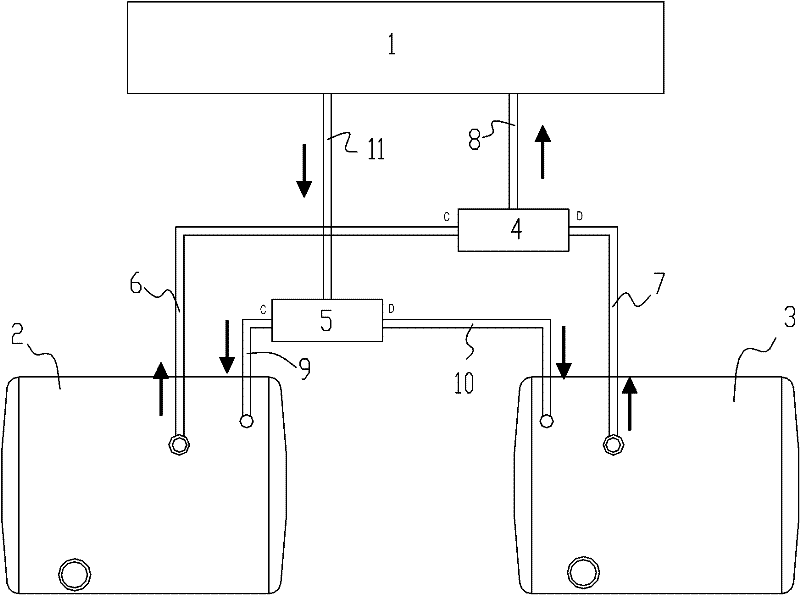

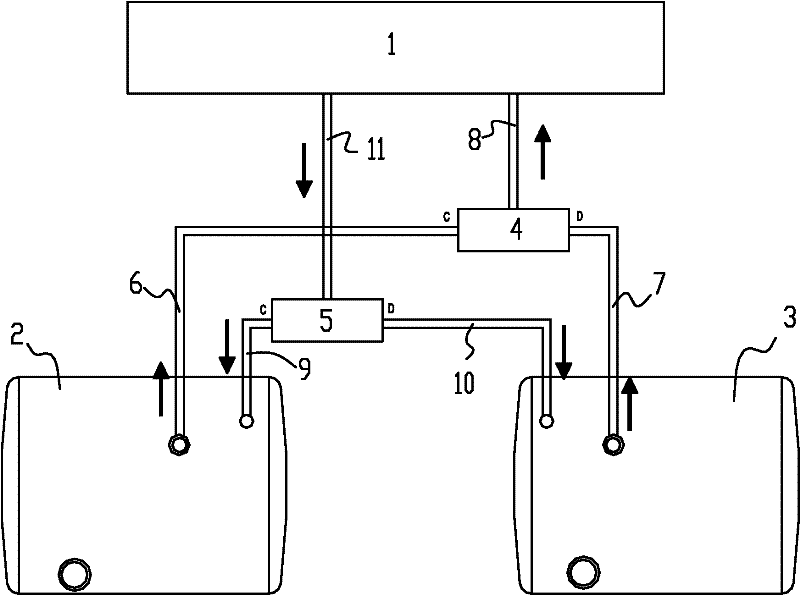

[0011] Referring to the accompanying drawings, a dual fuel tank fuel supply system for heavy trucks includes a fuel engine 1 and a fuel tank. The above-mentioned fuel tanks include a No. 1 fuel tank 2 and a No. 2 fuel tank 3, and the No. 1 fuel tank 2 and the No. 2 fuel tank 3 can alternatively be connected to a fuel engine.

[0012] More specifically, the fuel delivery pipeline 6 of the No. 1 fuel tank 2 and the fuel delivery pipeline 7 of the No. 2 fuel tank 3 are connected to the main fuel delivery pipeline 8 communicating with the fuel engine 1 through the first synchronization valve 4 . The oil return line 9 of the No. 1 fuel tank 2 and the oil return line 10 of the No. 2 fuel tank 3 are connected to the main oil return line 11 communicated with the fuel engine through the second synchronous valve 5 .

[0013] In the above method, when the selection control first and second synchronous valves are both in the C state, the fuel in the No. 1 fuel tank enters the fuel engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com