Device and method for eliminating welding stress of steel pipe ring beam by mechanical vibration

A technology of mechanical vibration and welding stress, which is applied in the field of steel structure welding, can solve the problem that the vibration wave energy of the vibration pickup cannot be transmitted, the clamping and positioning of the vibration pickup and the structural parts are difficult, and the reliability of the contact between the vibration pickup and the structural parts is difficult. Guarantee etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

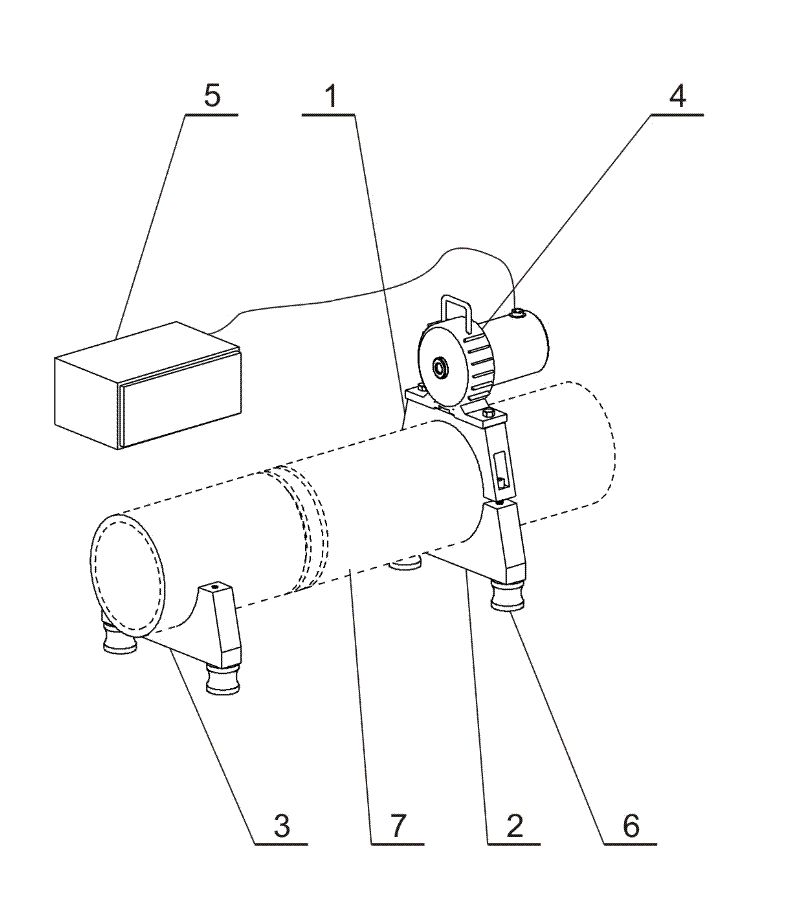

[0025] Project overview: The main steel structure of the curtain wall of the Shanghai Center, the main component of the main steel structure is a steel pipe ring beam structure, and its main parameters are 60m in chord length and 5.8m in arch height. The pipe shaft sliding telescopic node and the steel pipe ring beam tie rod hanging lug plate are welded. The process of the inner ring steel pipe ring beam and the outer ring steel pipe ring beam is: Butt jointing of sliding expansion joints, welding, installation of welding tie rods and lug plates, and overall elimination of welding stress on the steel pipe ring beam 7 after welding.

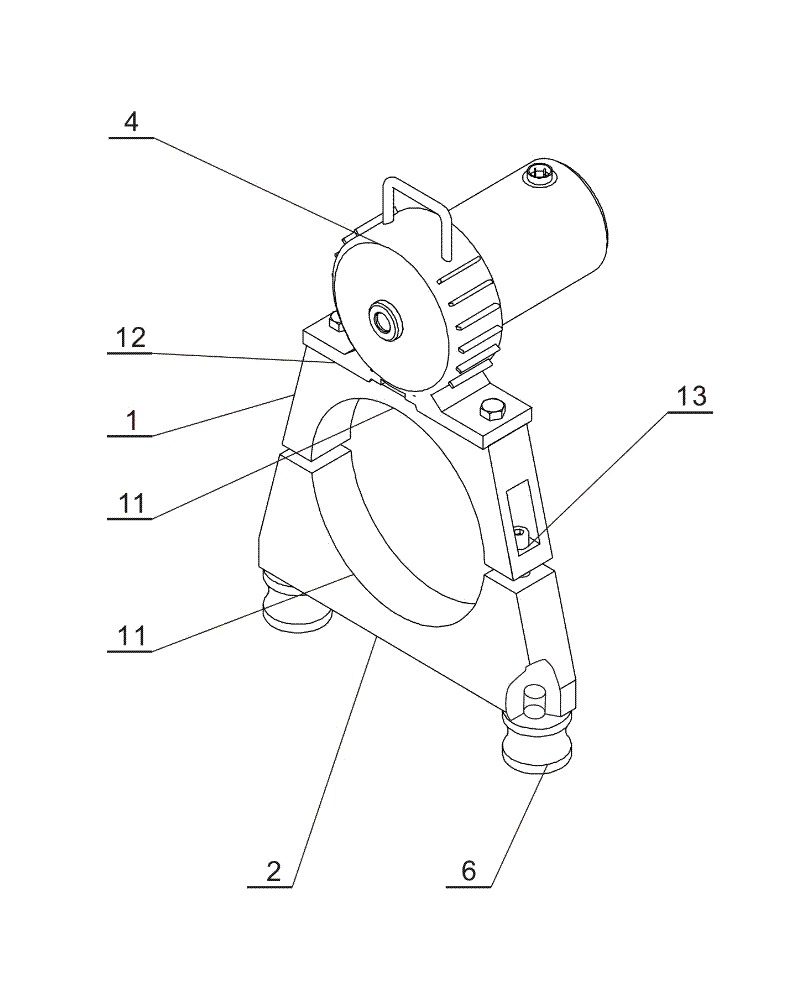

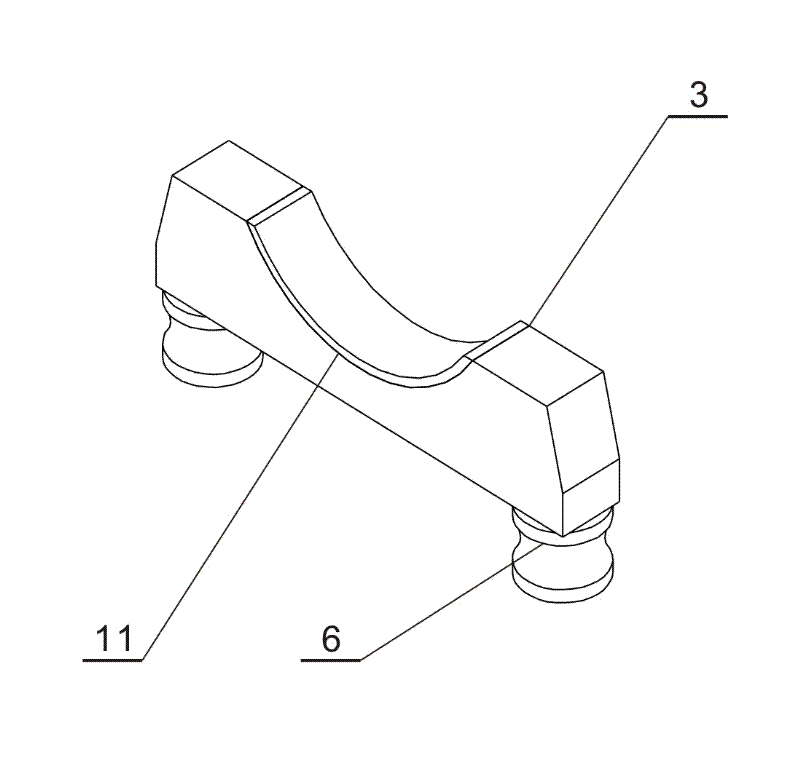

[0026] refer to figure 1 , figure 2 , image 3 The device of the present invention comprises an upper pipe seat 1, a lower pipe seat 2, a steel pipe ring beam rest seat 3, a vibration pickup 4, a frequency control box 5 and a rubber foot 6, and the upper pipe seat 1 and the lower pipe seat 2 are all There is a semi-circular pipe collar 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com