Bisecting and marking gauge

A regular and symmetrical technology, applied in the field of division and planning, can solve the problems of troublesome use and low efficiency, and achieve the effect of overcoming trouble and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

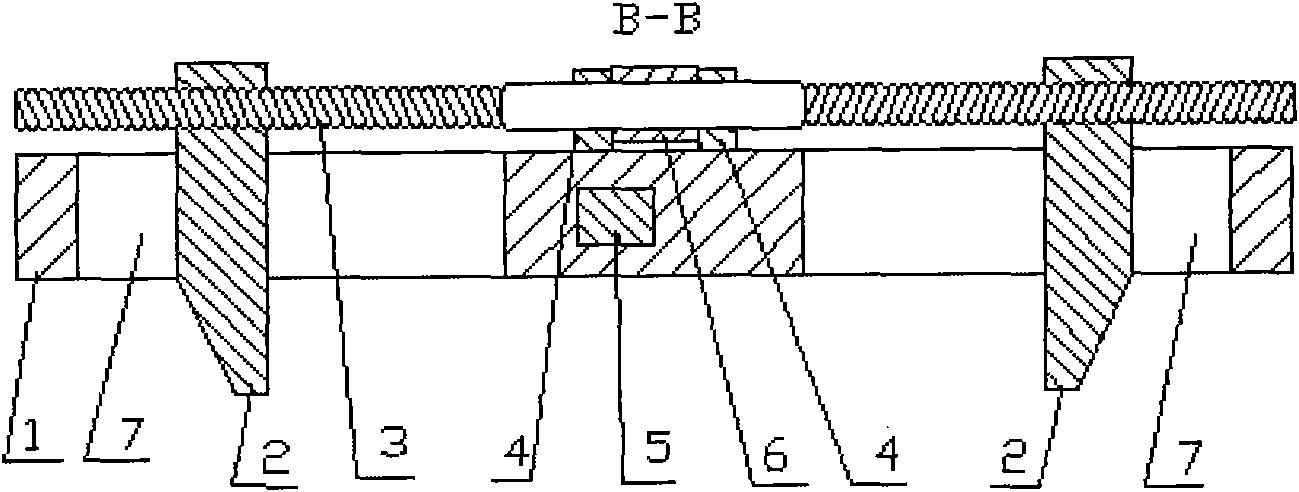

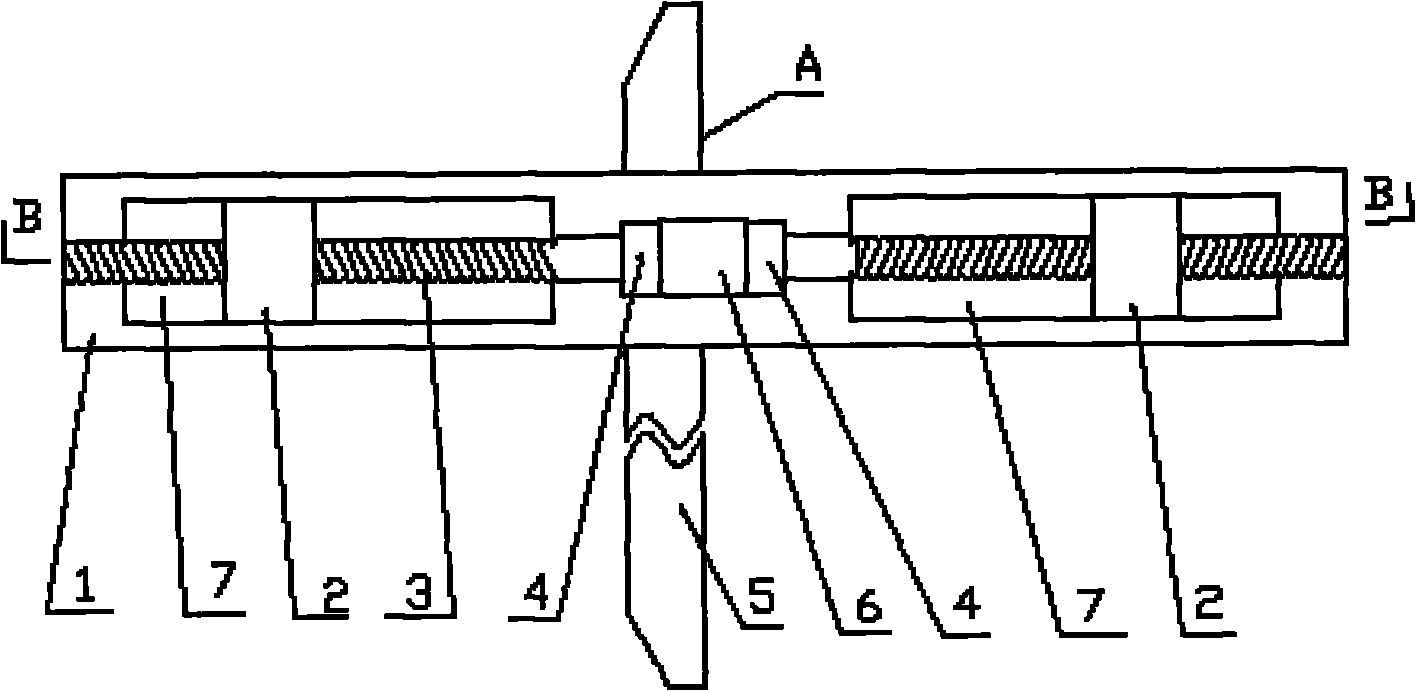

[0010] Produce guide rail (7) symmetrically on both sides of the planning body (1), also make a slide hole perpendicular to the planning body at the middle part of the planning body, install a sliding ruler (5) in the sliding hole, When installing, ensure that the A side of the sliding ruler (5) is always perpendicular to the sides C and D of the ruler body (1), the screw seat (4) is installed and fixed directly above the ruler body (1), and the knob (6) Installed on the screw base (4) through the middle of the screw (3), the connection between the knob (6) and the screw (3) is a fixed connection, and the movable grip (2) is composed of the same two pieces , the movable catch (2) is installed symmetrically on both sides of the lead screw (3) through threaded fit, and at the same time, is installed in the guide rails (7) on both sides of the planning body (1), the lead screw (3) The pitches of the threads at both ends are equal but in opposite directions. Therefore, during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com