Hydraulic anti-rotation self-unlocking device and hoisting and transporting vehicle using same

An anti-rotation and self-unlocking technology, which is applied in the direction of crane transportation, fluid pressure actuating device, crane, etc., can solve the problems of insufficient safety, trouble, and inability to guarantee absolute safety, etc., to achieve large locking force, overcome trouble, and prevent accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

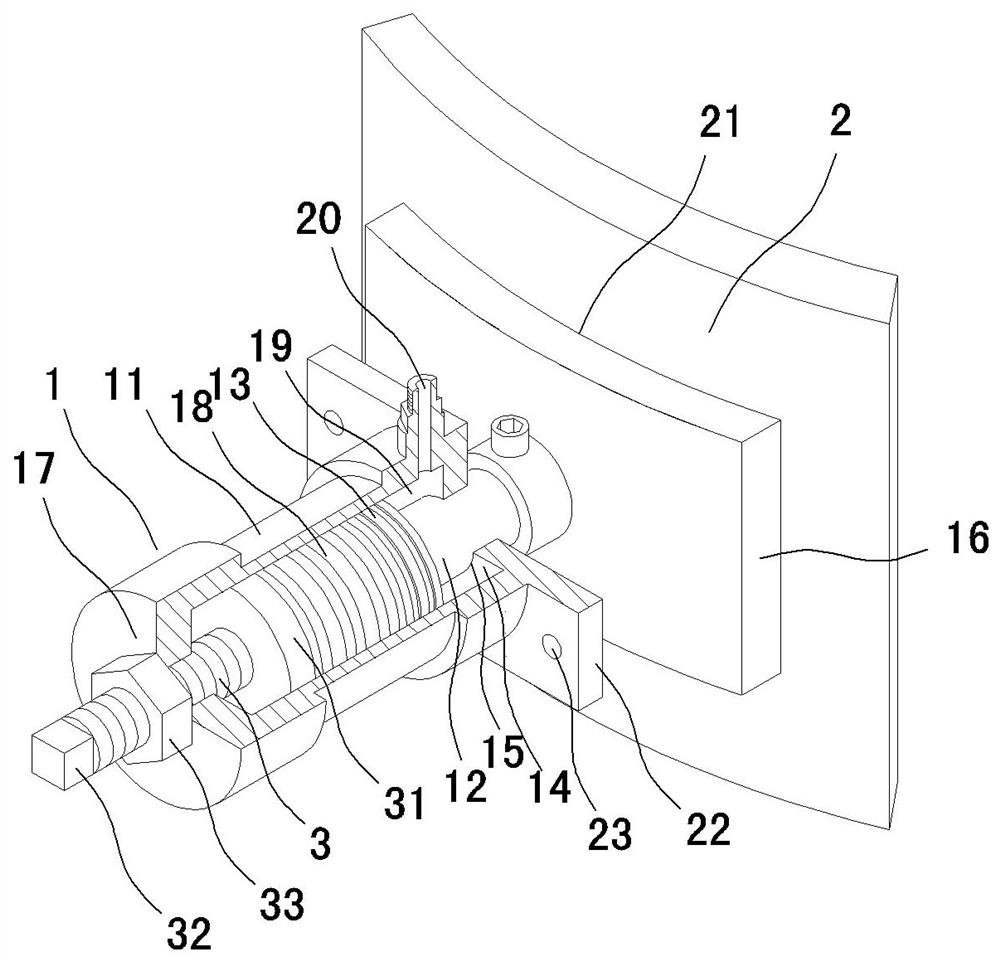

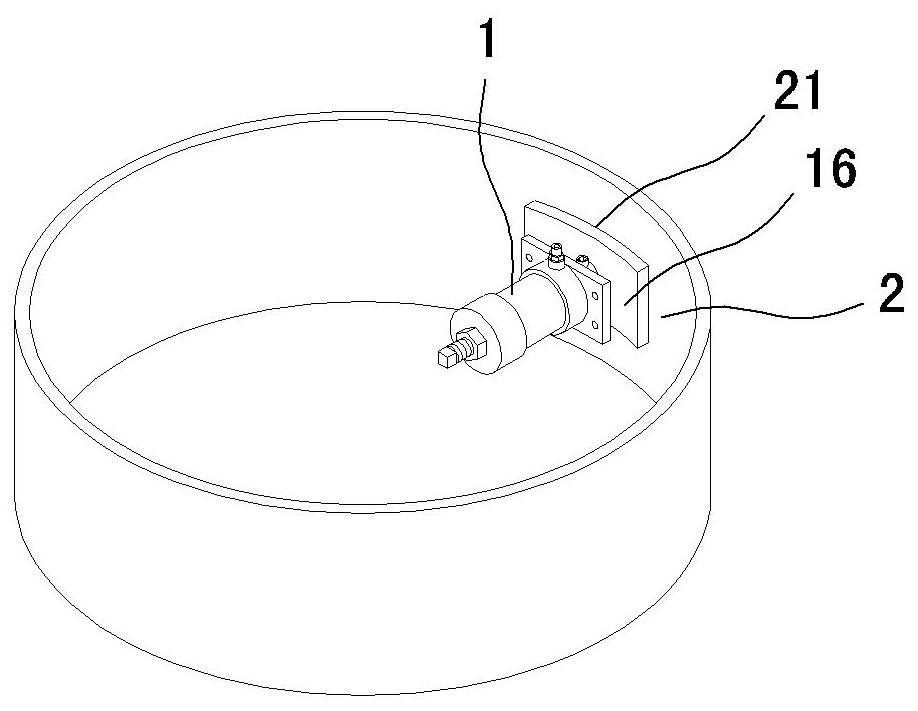

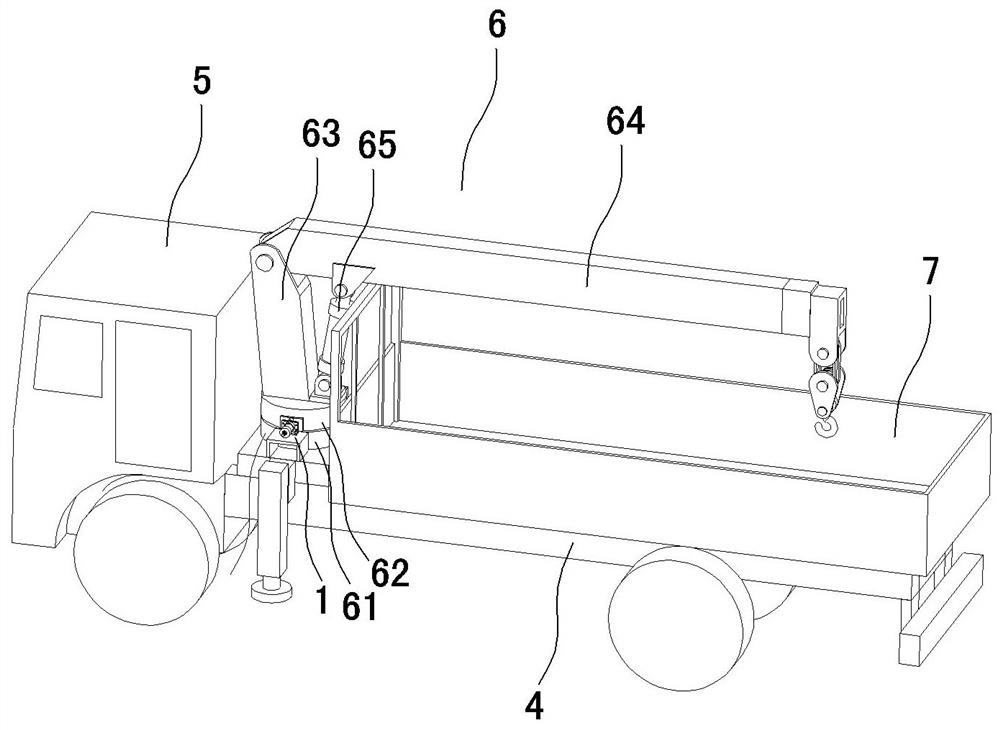

[0011] like figure 1 As shown in the figure, the hydraulic anti-rotation self-unlocking device includes an anti-rotation self-unlocking hydraulic cylinder 1 and a rotary locking surface 2 respectively arranged on two parts that are rotatably matched with each other. The anti-rotation self-unlocking hydraulic cylinder 1 includes a cylinder block 11, Cylinder rod 12 and piston 13, cylinder rod 12 and cylinder rod hole 15 on the front end cover 14 of cylinder block 11 are axially sliding and sealingly matched, piston 13 is slidably installed in cylinder block 11 and fixedly installed at the rear end of cylinder rod 12, The front end of the cylinder rod 12 located outside the cylinder body 11 is provided with a friction locking block 16 which is matched with the rotary locking surface 2 . The cylinder body 11 is provided with a number of butterfly springs located between the piston 13 and the rear end cover 17 of the cylinder body 11 . 18. The side wall of the cylinder block 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com