Device for quickly screwing steel bar splicing sleeve

A technology of connection and sleeve, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of unsuitable connection of two sections of steel mesh cages, small wrench rotation angle, high labor intensity, etc., to achieve clamping or It is convenient and fast to loosen the workpiece, convenient and fast to clamp the workpiece, and overcome the troublesome effect of connecting the sleeve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

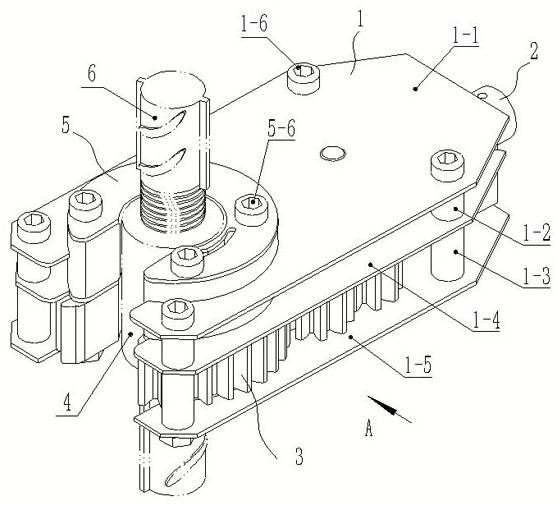

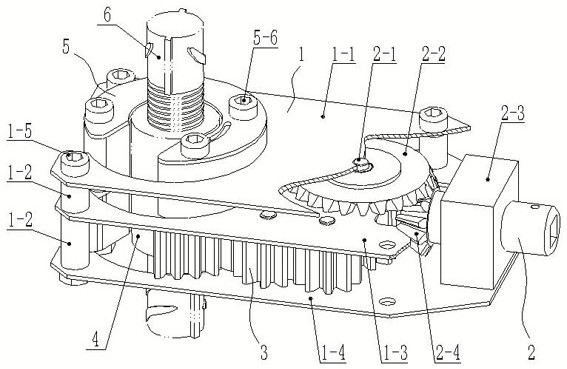

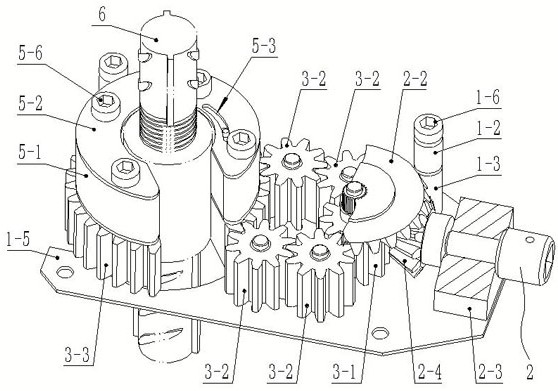

[0028] Such as Figure 1-12 As shown: the frame 1 is composed of an upper plate 1-1, a middle plate 1-4, a bottom plate 1-5 arranged from top to bottom, and four upper plates supported between the upper plate 1-1 and the middle plate 1-4. The spacer 1-2 is composed of four lower spacers 1-3 supported between the middle plate 1-4 and the bottom plate 1-5; and passes through the upper plate 1-1 and the upper spacer 1 respectively from top to bottom -2. The four frame connecting bolts 1-6 of the middle plate 1-4, the lower spacer 1-3 and the bottom plate 1-5, and the nuts matched with the connecting bolts 1-6 of each frame (not shown in the figure) The connection is fixed. There are positioning holes on the corresponding positions of the upper plate 1-1, the middle plate 1-4 and the bottom plate 1-5, and the left sides of the three plates are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com