Roll paper cold iron printing equipment and operation method thereof

A technology of printing equipment and web, which is applied in the field of printing equipment for the cold ironing process of web, can solve the problems of inflexibility of the whole machine process, affecting the speed of the whole machine, and the inability to realize skipping, so as to shorten the adjustment time and reduce the production The cost of consumables and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

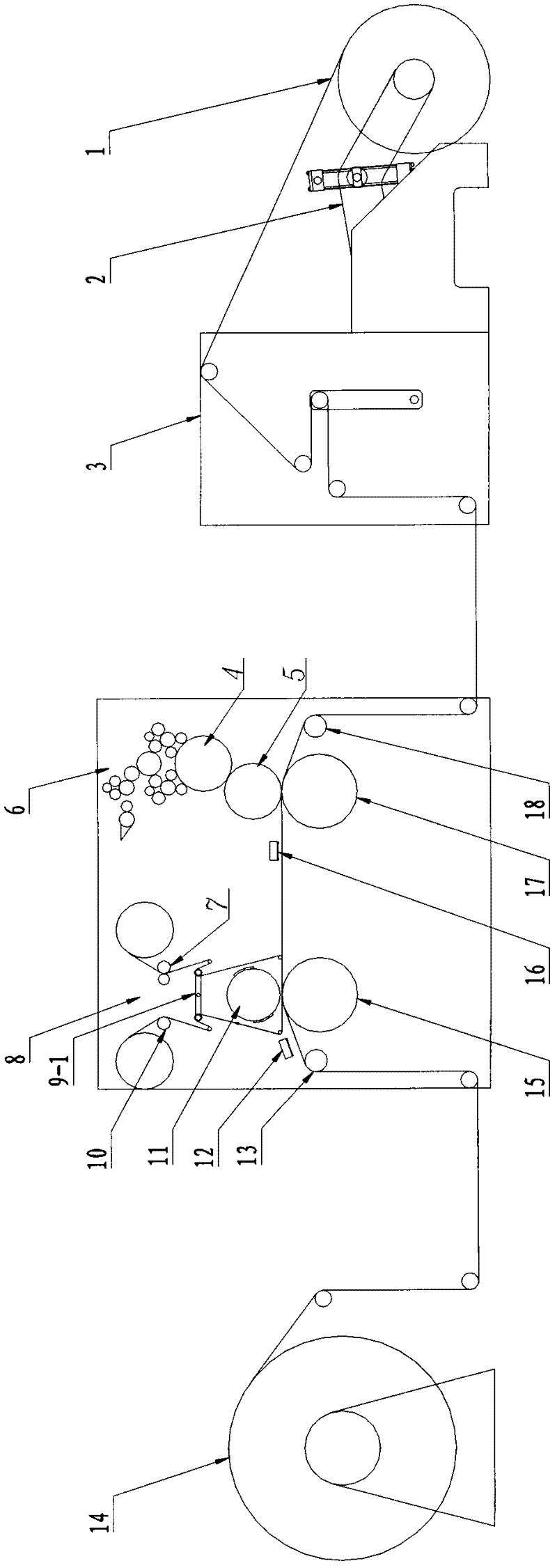

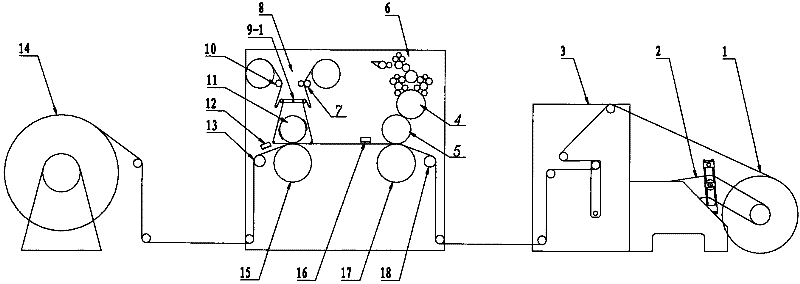

[0027] Embodiment 1: a kind of web cold pressing printing equipment (see figure 1 ), is characterized in that it comprises unwinding unit 2, tension control unit 3, gluing unit 6, cold perm unit 8 and winding unit 14; The output of described unwinding unit 2 connects the input end of tension control unit 3; The described The output of the tension control unit 3 is connected to the input of the gluing unit 6; the output of the gluing unit 6 is connected to the input of the cold pressing unit 8; the output of the cold pressing unit 8 is connected to the input of the winding unit 14.

[0028] Above-mentioned gluing unit 6 (seefigure 1 ) is made up of gluing roller 4, transfer roller 5, gluing UV curing device 16, gluing printing roller 17 and gluing traction roller 18; described transfer roller 5 is positioned at gluing printing roller 17 The top of the web 1 passes between the rubberized printing roller 17 and the transfer roller 5, and the transfer roller 5 is pressed on the we...

Embodiment 2

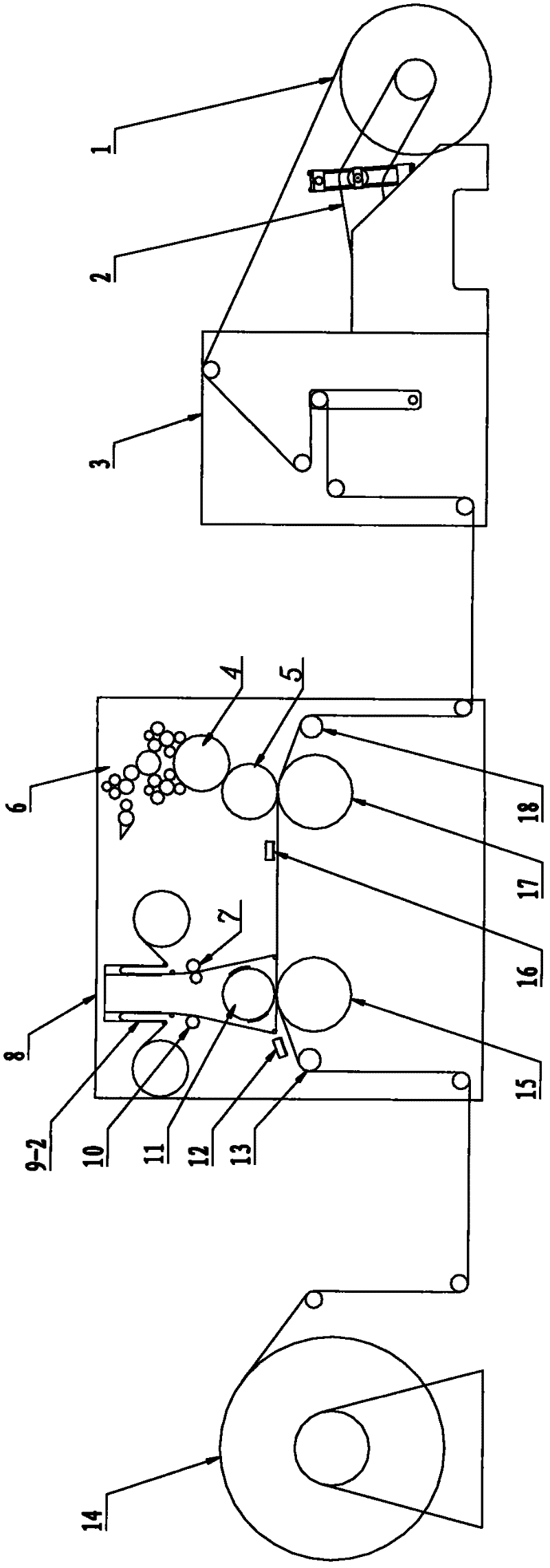

[0041] Embodiment 2: a kind of web cold pressing printing equipment (see figure 2 ), is characterized in that it comprises unwinding unit 2, tension control unit 3, gluing unit 6, cold perm unit 8 and winding unit 14; The output of described unwinding unit 2 connects the input end of tension control unit 3; The described The output of the tension control unit 3 is connected to the input of the gluing unit 6; the output of the gluing unit 6 is connected to the input of the cold pressing unit 8; the output of the cold pressing unit 8 is connected to the input of the winding unit 14.

[0042] Above-mentioned gluing unit 6 (see figure 2 ) is made up of gluing roller 4, transfer roller 5, gluing UV curing device 16, gluing printing roller 17 and gluing traction roller 18; described transfer roller 5 is positioned at gluing printing roller 17 The top of the web 1 passes between the rubberized printing roller 17 and the transfer roller 5, and the transfer roller 5 is pressed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com