Medium-temperature cobalt blue disperse dye

A disperse dye, medium temperature technology, used in azo dyes, organic dyes, monoazo dyes, etc., can solve the problem of low color yield, and achieve excellent fastness to sunlight and washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

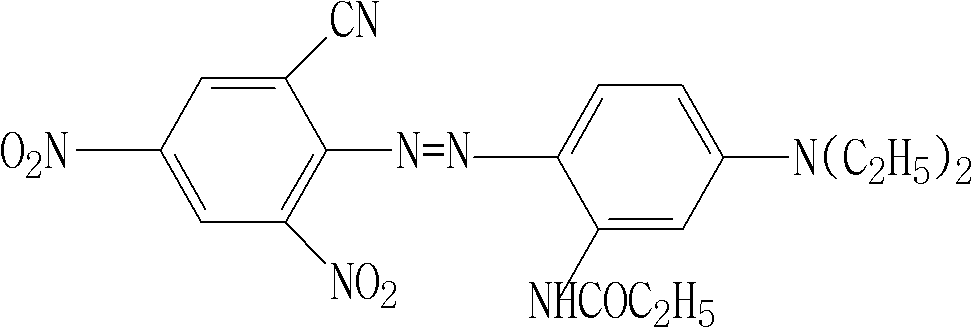

[0026] Add 40 milliliters of 98% sulfuric acid in a 250 milliliter four-necked flask, add 9.95 grams of 98 percent 3-amino-5-nitro-2,1-benzisothiazole under stirring, stir to dissolve completely, then 17 g of 40% nitrosyl sulfuric acid was slowly added dropwise at 10°C. React to the end at this temperature to obtain a diazonium solution to be coupled.

[0027] Add 400 milliliters of water in the 2000 milliliter flask, then slowly add 10 milliliters of sulfuric acid while stirring. Then add 13.4 grams of 98% N-ethyl-N-p-methylbenzyl m-toluidine (0.05 gmol) and stir until dissolved , cool down on an ice-water bath, and at the same time add an appropriate amount of crushed ice to the cup to cool down to 0-5°C, start adding the above-mentioned diazo solution dropwise, keep the reaction at 0-5°C until the diazo component disappears, filter and wash with water until neutral. Obtain about 90 grams of filter cake, and the average weight of dry dyestuff is 18 grams. The dye is dissol...

preparation example 2-4

[0031] Dye synthesis conditions and ingredient molecular ratio are the same as Preparation Example 1, the only difference is that N-ethyl-N-p-methylbenzyl m-toluidine in Preparation Example 1 is replaced, and Preparation Example 2 is replaced by N-ethyl-N- M-methylbenzyl m-toluidine, preparation example 3 is replaced by N-ethyl-N-p-chlorobenzyl m-toluidine, preparation example 4 is replaced by N-butyl-N-p-chlorobenzyl m-toluidine, obtaining The general formula and corresponding properties of dyes are shown in the following table:

[0032] Example

preparation example 5

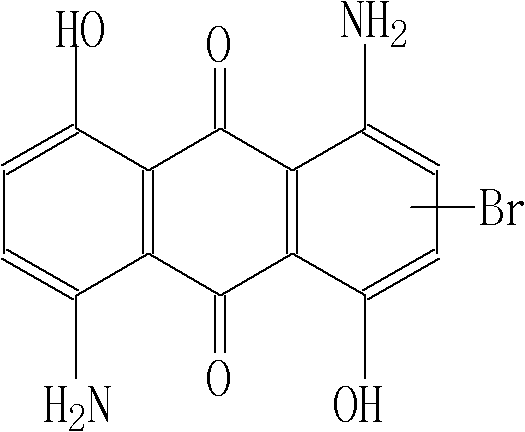

[0034] Dye synthesis conditions and batching ratio are the same as Preparation Example 1, wherein 0.05gmol N- Ethyl-N-p-methylbenzyl-m-toluidine to give the corresponding dye. Its absorption wavelength is λ max =620nm. The dye is a mixed dye, and its structural formula is:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com