Fully mechanized coal mining method combining steeply inclined long-wall drilling type coal mining machine with hydraulic shield type supports

A shearer, steep incline technology, applied in earth-moving drilling, mine roof support, ground mining, etc., can solve problems such as difficulty in moving the support down, small adaptability to changes in coal seam thickness, poor support safety, etc., and achieve mining conditions. Safe and reliable, avoid drilling holes and blasting coal, and use safe and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

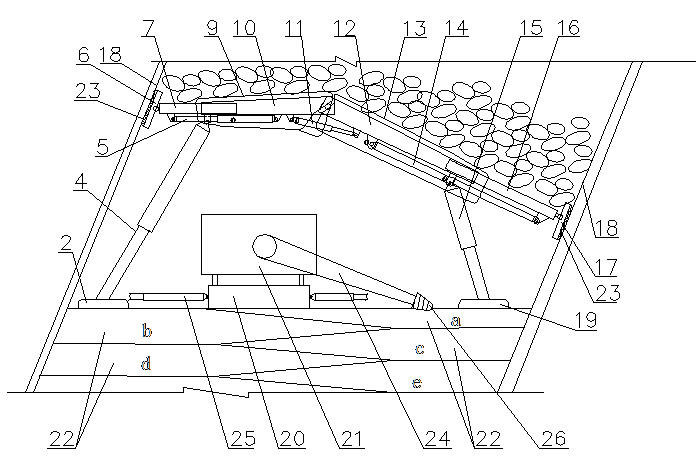

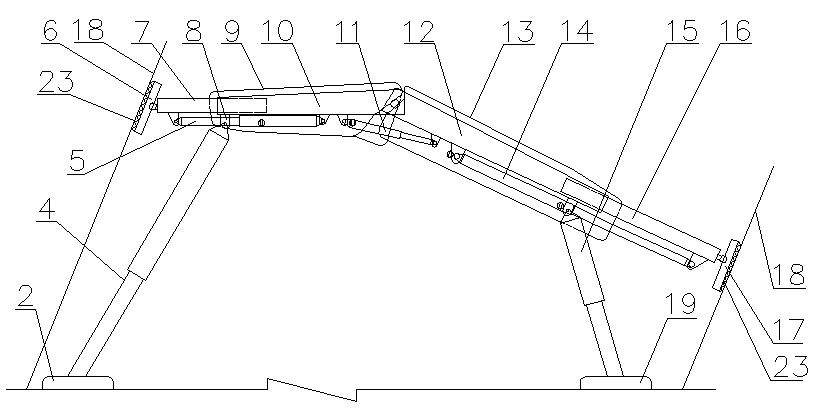

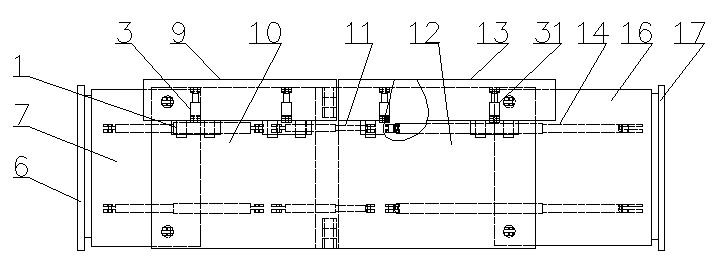

[0025] like figure 2 and image 3 The shown hydraulic shielding support includes a main beam 10 and a shielding beam 12, the main beam 10 is hinged with the inner end of the shielding beam 12, and the inner ends of the main beam 10 and the shielding beam 12 are hingedly equipped with a balance hydraulic cylinder 11, and the balance The hydraulic cylinder 11 is located below the inner hinge of the main beam 10 and the cover beam 12, and is used to adjust the support angle between the main beam 10 and the cover beam 12 to adapt to the change of the coal seam angle and ensure that the support is in an ideal support position. The outer ends of the main beam 10 and the cover beam 12 are respectively movably inserted with a telescopic front beam 7 and a telescopic rear beam 16. The main beam 10 and the telescopic front beam 7 are connected with a front telescopic hydraulic cylinder 5, and the cover beam 12 is connected with the telescopic rear beam 16. Rear telescopic hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com