Rotary lamp cap

A technology of rotating the lamp head and rotating the ground, which is applied to lighting devices, lighting device parts, lighting auxiliary devices, etc., can solve the problems of high cost, complex structure, unfavorable replacement of light sources, etc., and achieve the effect of convenient change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

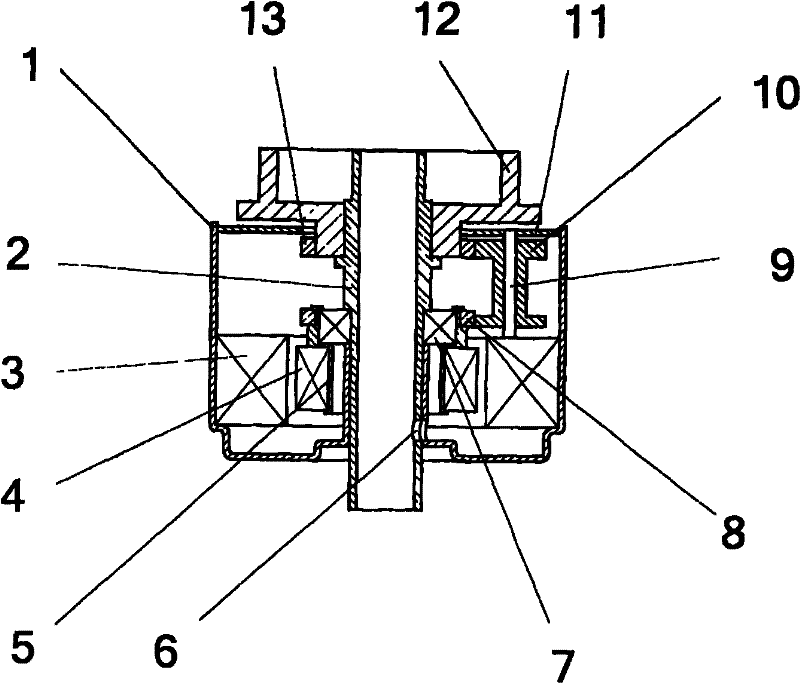

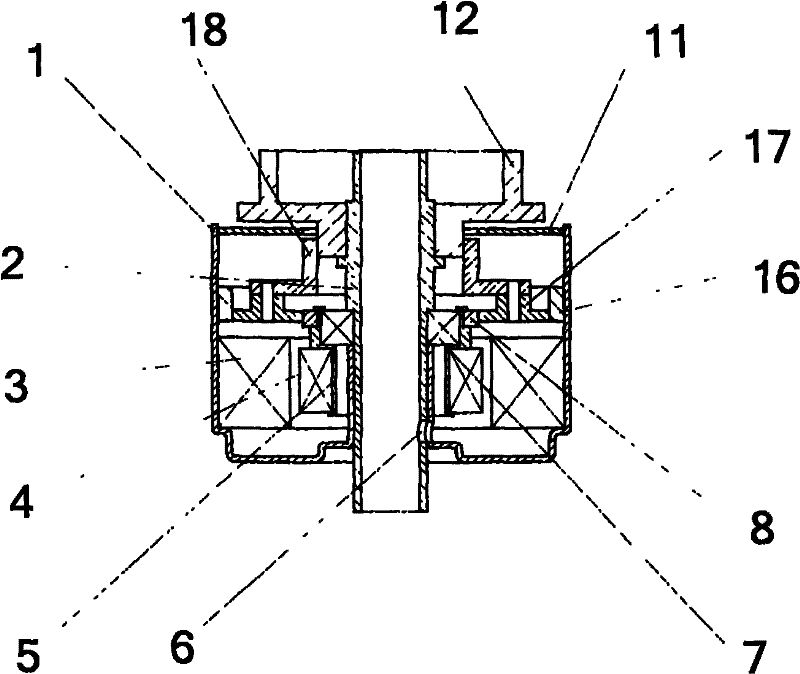

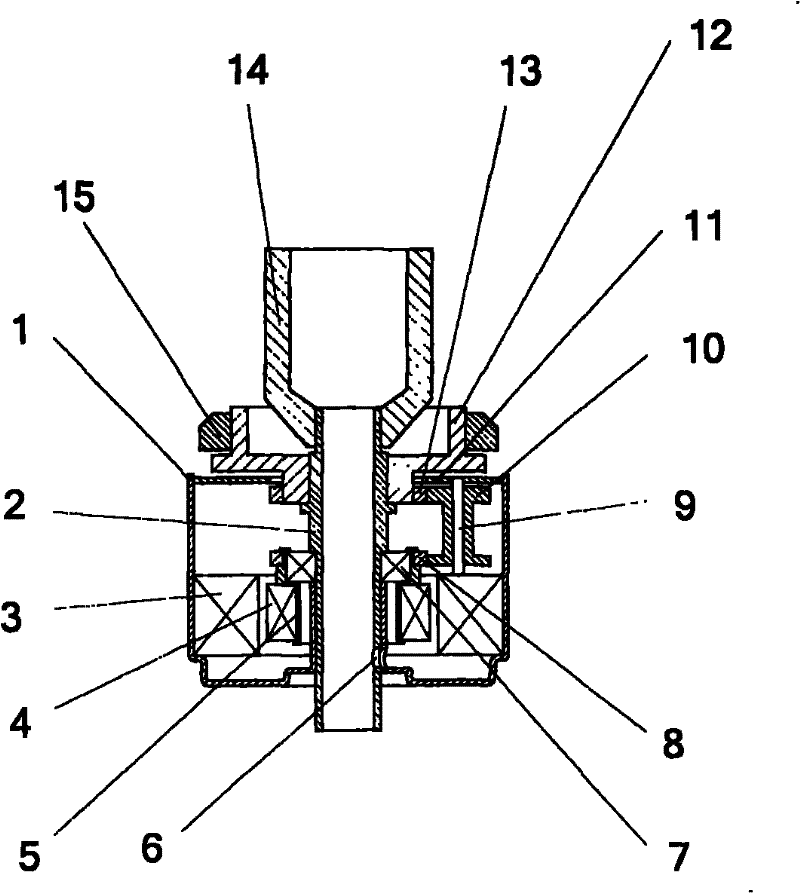

[0044] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0045] See figure 1 The rotating lamp cap (or simply called “motor”) according to the first embodiment of the present invention includes a substantially cylindrical or cylindrical housing 1. The housing 1 has a first longitudinal end and an opposite second longitudinal end. The first longitudinal end of the housing 1 is closed by a cover 11. Both the first and second longitudinal ends are provided with a central opening to allow the substantially cylindrical lead post 2 to pass longitudinally.

[0046] The motor stator 3 is provided around the inner peripheral surface of the housing 1. The (hollow) rotating shaft 5 is rotatably mounted around the lead column 2 via a bearing 7. The motor rotor 4 is fixed on the rotating shaft 5 and arranged coaxially with the motor stator 3. The lead post 2 passes through the longitudinal cavity of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com