display device

一种显示装置、透明基板的技术,应用在辨认装置、离子注入镀覆、涂层等方向,能够解决密接性下降、氮化铜不是、配线膜劣化等问题,达到形状优良、构图容易、低电阻率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] (production of samples)

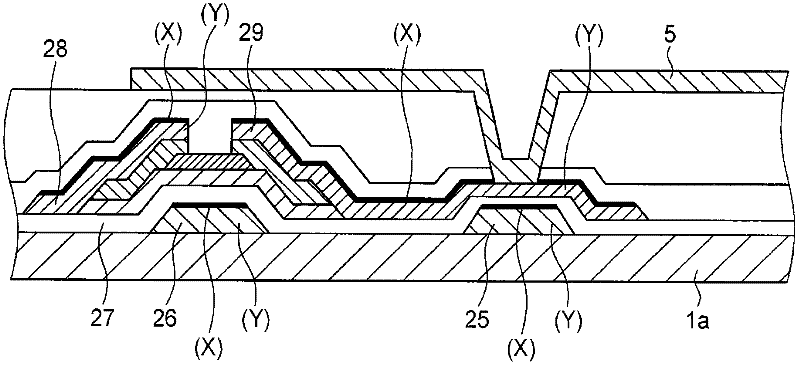

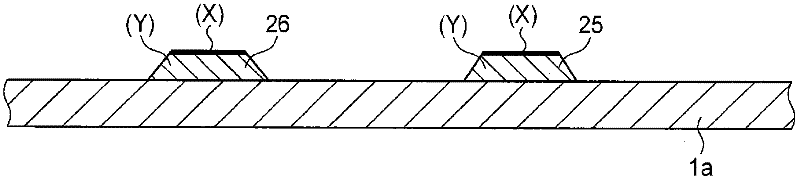

[0097] In this example, the type and content of the Cu alloy constituting the first layer (Y) and the thickness of the first layer (Y) were investigated for the samples (No. 3 to 35) in Table 1 prepared as follows Effects on resistivity and adhesion to glass substrates.

[0098] A Cu alloy containing various elements shown in Table 1 was fabricated as the first layer (Y) by the sputtering method as follows, and a Cu alloy film composed of a laminated structure of pure Cu was fabricated as the second layer (X) . In Table 1, No. 3 to 16 are examples of adding Mn as an element constituting the first layer (Y), No. 17 is an example of adding Bi, No. 18 to 21 are examples of adding Ni, and No. 21 to No. 23 is an example of adding Zn, No. 24-25 is an example of adding Al, No. 26-27 is an example of adding Ti, No. 28-29 is an example of adding Mg, No. 30-31 is an example of adding Ca , Nos. 32-33 are examples in which Nb is added, and No. 34-35 are...

Embodiment 2

[0131] In this example, the adhesiveness after the DC stress test and the peeling test when using the soda-lime glass substrate was examined about the samples (this invention example and comparative example) produced as follows. The DC stress test is to maintain a certain distance and apply a certain driving voltage (direct current, DC), that is, stress, between the electrically separated patterns to maintain a certain electric field strength between the patterns, and to check the change of the leakage current between the electrodes. , peeling or formation of foreign matter and other appearance inspection methods. By applying a voltage higher than the normal applied voltage in a constant temperature and humidity atmosphere (temperature 80°C, humidity 80%), it is possible to inspect the wiring generated by the movement of charges caused by normal panel operation in a short time The exception checking method is useful. Here, two comb-shaped electrode patterns formed with a line...

Embodiment 3

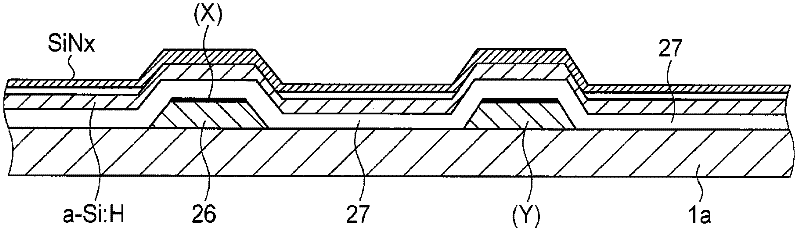

[0145] In this example, the constituent element of the first layer (Y) is Mn, and the effects of the content of Mn and the film thickness of the first layer (Y) on the adhesion to the glass substrate and the resistivity were further studied in detail.

[0146] (1) Evaluation of Adhesion with Glass Substrate

[0147] Except for the case where the glass substrate is EAGLE2000 (diameter: 4 inches x thickness: 0.7 mm) manufactured by Corning, and the film thickness of the first layer (Y) varies between 5 and 100 nm and the second layer (X) A laminated film of the first layer (Y) and the second layer (X) was formed on a glass substrate in the same manner as in Example 1 except that the film thickness was constant at 500 nm. After film formation, heat treatment was performed at 320° C. for 5 minutes under a nitrogen atmosphere of 1 Pa using a CVD apparatus. Next, use a cutter to form 5×5 grid-shaped incisions at 1 mm intervals on the film-forming surface, and firmly stick 8422B tap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com