Instrument housing

A technology of instrument shell and shell, applied in the direction of instruments, shells, instrument parts, etc., can solve the problems of long operation time, fragility, corrosion of connecting and unloading terminals, etc., and achieves low cost, simple structure and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

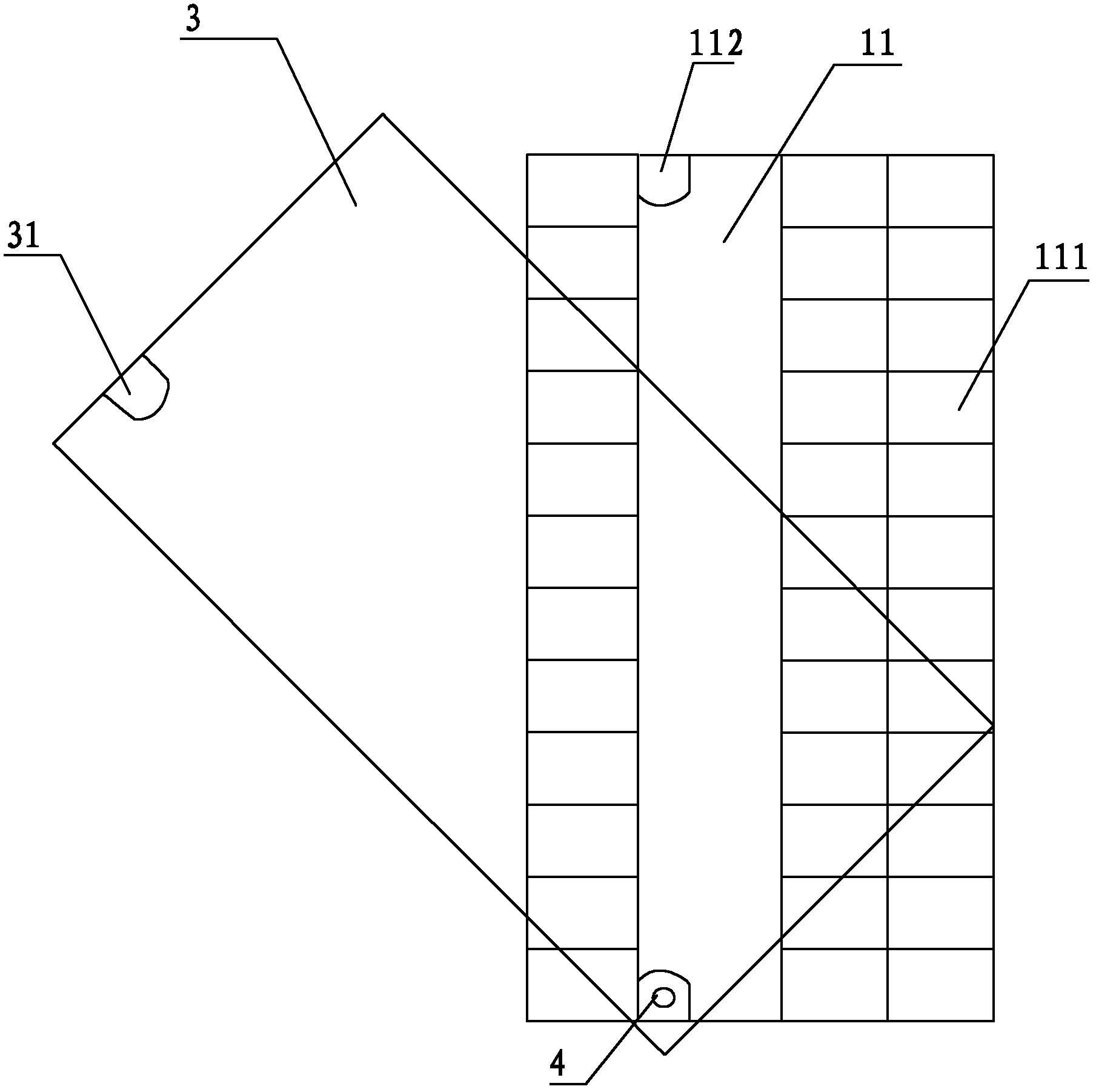

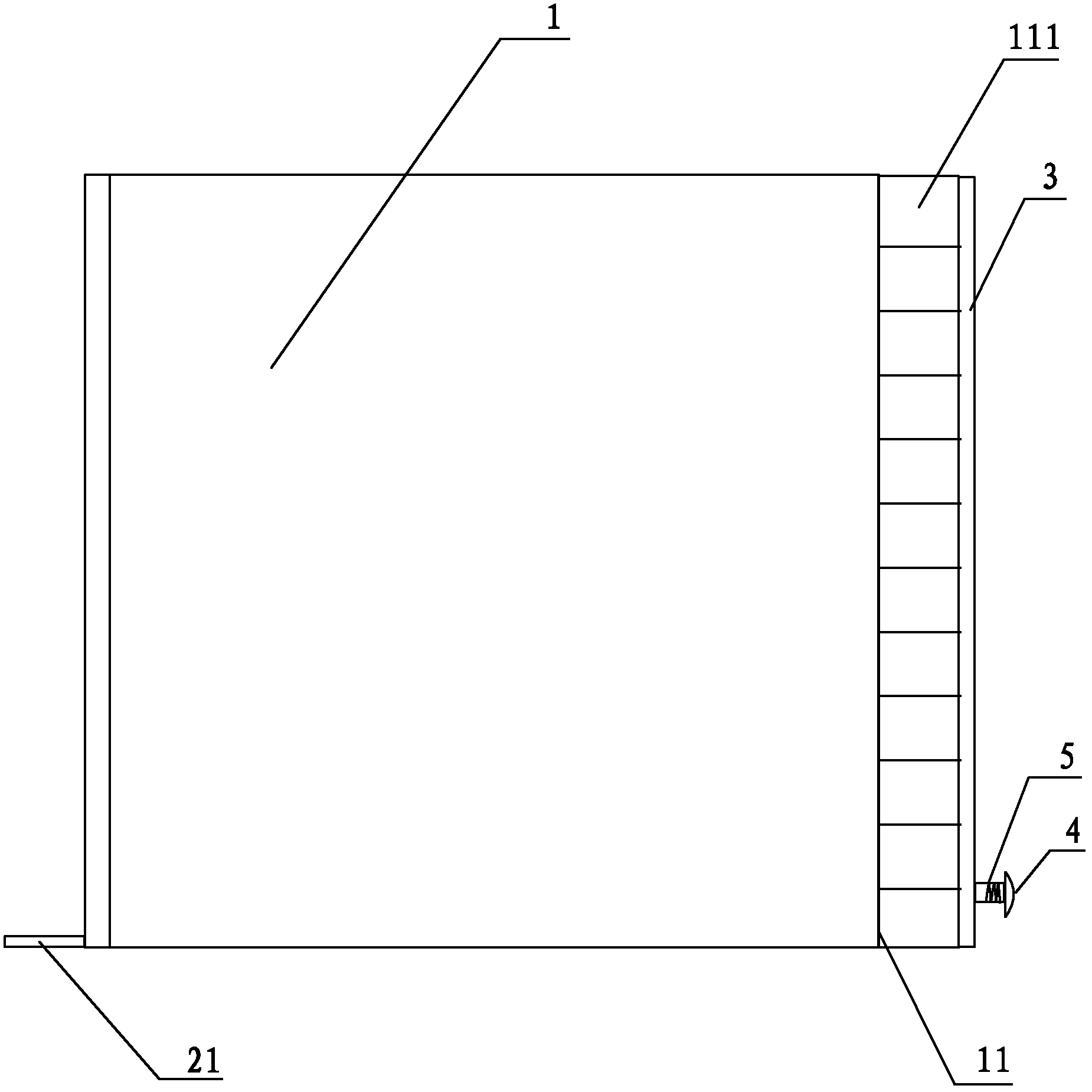

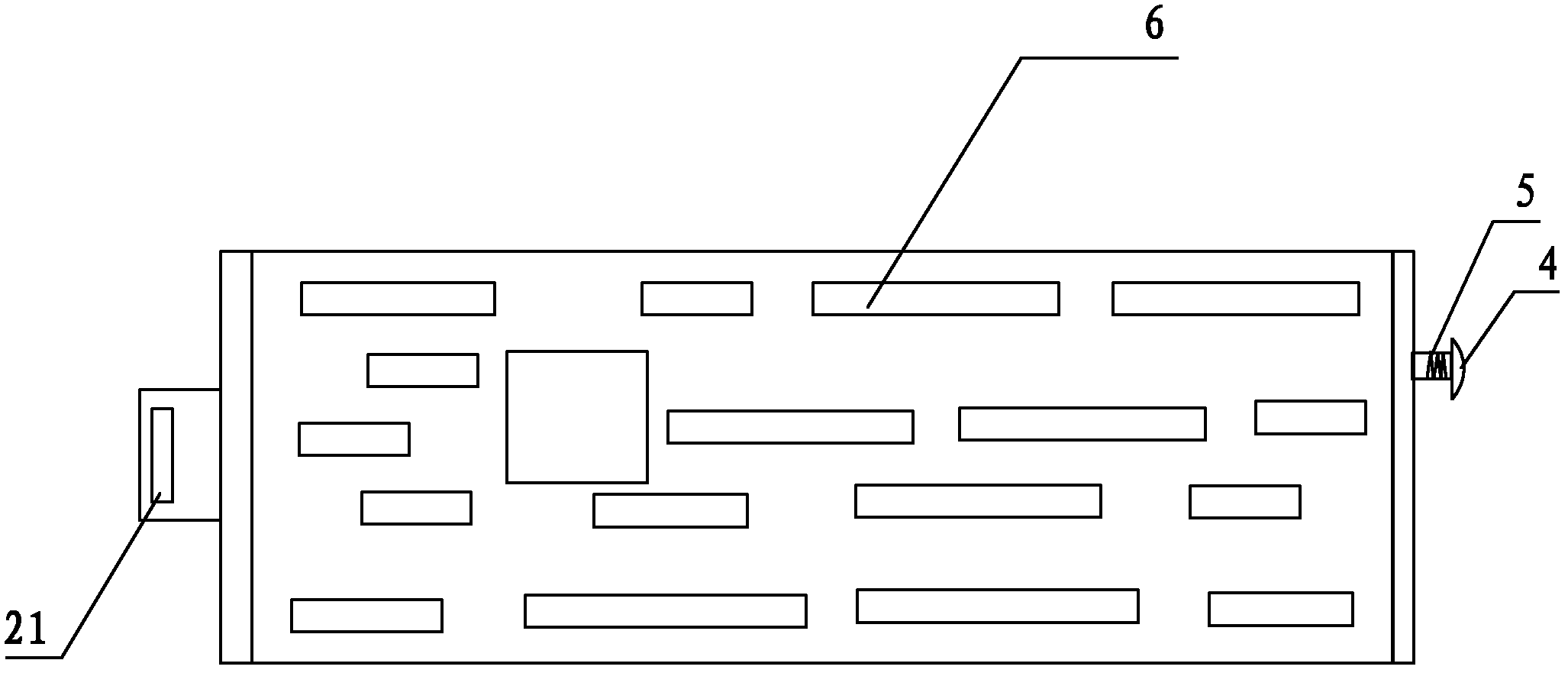

[0021] Refer to attached figure 1 And attached figure 2 , shown in the accompanying drawing is a kind of instrument casing 1 of the present invention, comprises: casing 1, is made of 4 side panels fixed on the back plate 11 by the back plate 11, and it forms an open end; Front cover 2 , to cover the opening end of the housing 1; the instrument housing 1 is also provided with a rear cover 3, and the side of the rear board 11 facing away from the opening end is set as the outer side of the rear board 11, and the outer side of the rear board 11 is arranged with a fence type Connecting terminal 111, the rear cover 3 and the rear plate 11 are connected by the rotating shaft 4, the rotating shaft 4 is arranged on the rear plate 11, the rear co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com